Rotary kiln safety production protection system

A protection system and safe production technology, applied in general control system, control/regulation system, rotary drum furnace, etc., can solve problems such as scrapping of materials after firing, damage of electric lifting bars of mechanical structure of equipment, etc., and achieve stable pressure in the furnace , Improve production efficiency and avoid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

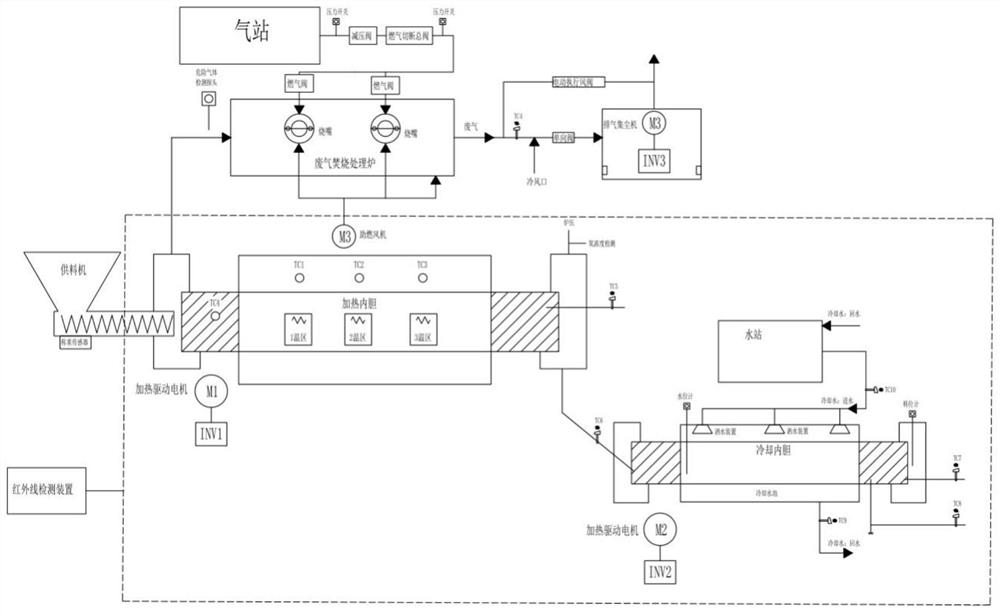

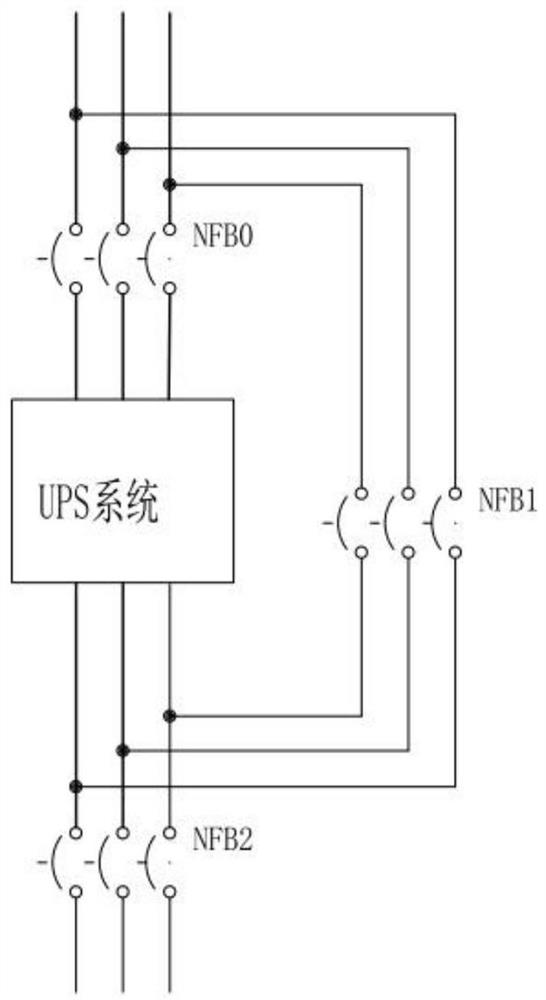

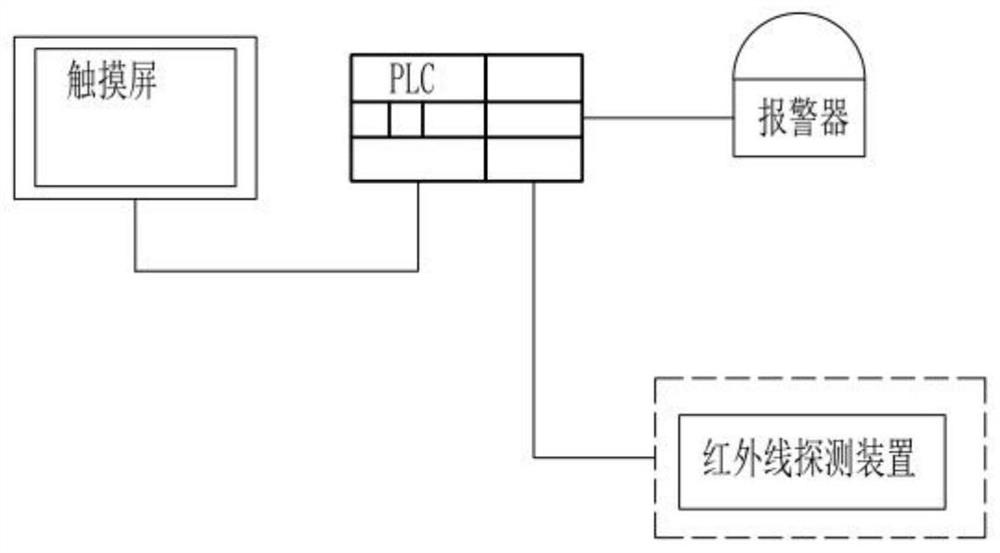

[0059] see Figure 1-23 The multiple safety subsystems of the rotary kiln, the safety production system operation protection UPS system during the power failure of the rotary kiln can effectively avoid the hazards caused by sudden power failure. The system mainly includes UPS power supply and the power control system of the entire rotary kiln. This system is mainly to install a UPS power supply at the control power supply of the rotary kiln. During normal power supply, the UPS acts as a voltage stabilizer, and at the same time charges the battery inside the machine. When the power is cut off, the UPS immediately supplies the electric energy in the battery to the control power supply. In this case, the PLC control system will switch the operation of the equipment to the power-off safe operation mode: in this mode, 1. The feeder stops running and no longer continues to feed materials into the kiln, and the inner tank (heating / cooling) remains 2. The heating circuit will be cut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com