A method for integrating local large-area welding board-level interconnection of hermetic packaging units

A technology of hermetic packaging and integration methods, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problem of low reliability of signal interconnection, improve tensile and shear strength, and reduce shear strain , The effect of high welding interface strength

Active Publication Date: 2022-05-31

SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

View PDF20 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Aiming at the above-mentioned deficiencies in the prior art, the present invention provides a local large-area soldered board-level interconnection integration method for hermetic packaging units to solve the problem of low reliability of the signal interconnection between the multilayer ceramic package and the system motherboard. The problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0048] In the present embodiment, tin-lead solder balls are selected as interconnect solder joints.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

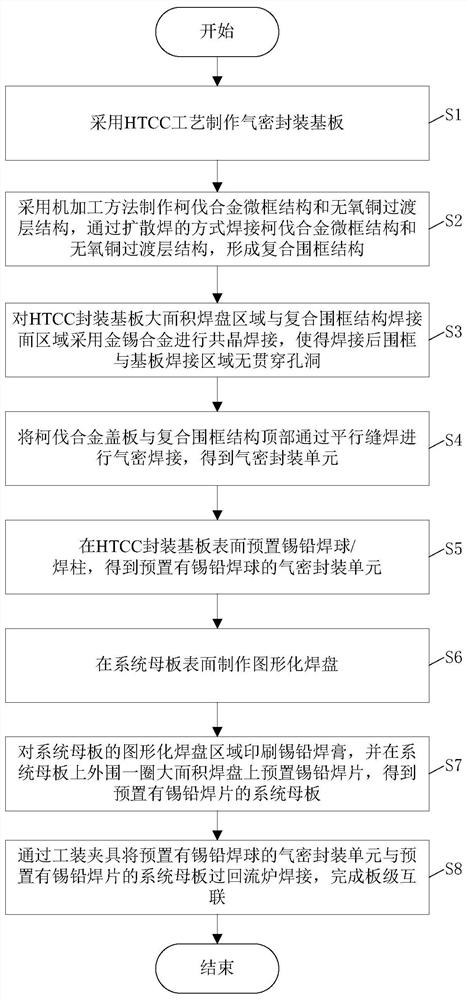

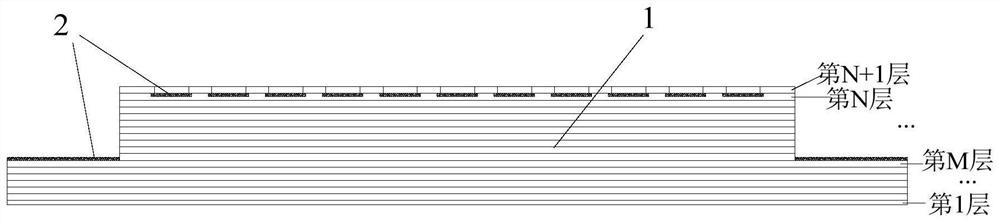

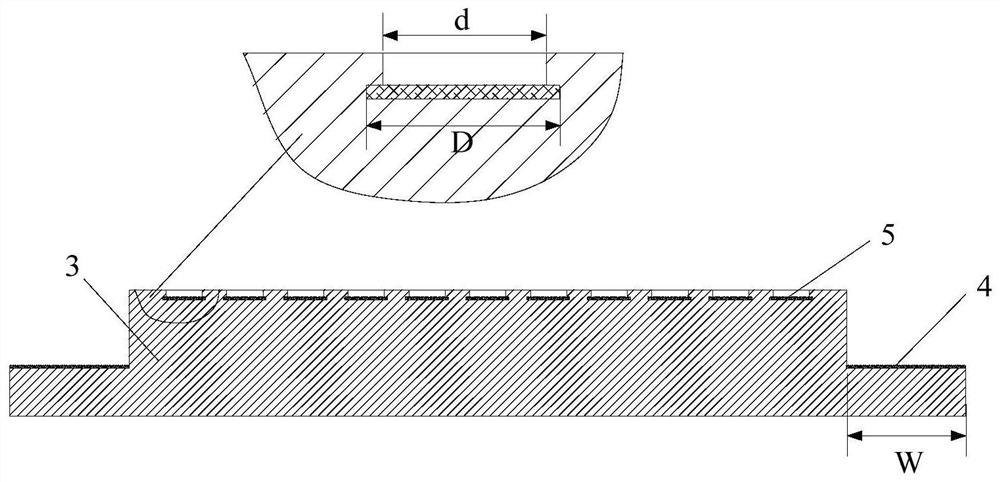

The invention discloses a local large-area welding plate-level interconnection integration method of a hermetic packaging unit. The local large-area welding board-level interconnection integration method of the pad-enhanced hermetic packaging unit involved in the present invention completes the production of the enhanced pad on the substrate through the HTCC process; by using multiple packaging substrates, composite enclosures, and cover plates Temperature gradient welding realizes airtight packaging; through the method of combined welding of tin-lead solder balls / solder columns and composite frame structure, the highly reliable board-level interconnection between the airtight packaging unit and the system motherboard is completed.

Description

A method for integrating local large-area welding board-level interconnection of hermetic packaging units technical field The present invention relates to the technical field of electronic packaging board-level interconnection, in particular to a local large-area hermetic packaging unit Solder board level interconnect integration method. Background technique [0002] The electronic complete machine has put forward higher requirements for package miniaturization, high density, versatility, high reliability, high power, etc. [0002] Therefore, the system-in-package form using co-fired multilayer ceramic substrates is widely favored. This multilayer ceramic package and system The signal interconnection between motherboards is usually realized by ball grid grid array (BGA) interconnection. However, multilayer ceramic substrates and system mother The thermal expansion coefficient of the board varies greatly. With the increase in the complexity of the package function and t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01L21/768H01L21/48

CPCH01L21/76895H01L21/4817

Inventor 王辉李阳阳庞婷董东卢茜曾策张继帆罗明张晏铭董乐李杨陆吟泉徐榕青向伟玮毛小红

Owner SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com