Polycrystalline self-doped smooth top gate JFET device and manufacturing method thereof

A self-doping and smoothing technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as difficulties for designers, improve the ability to accurately control threshold voltage, and improve device consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

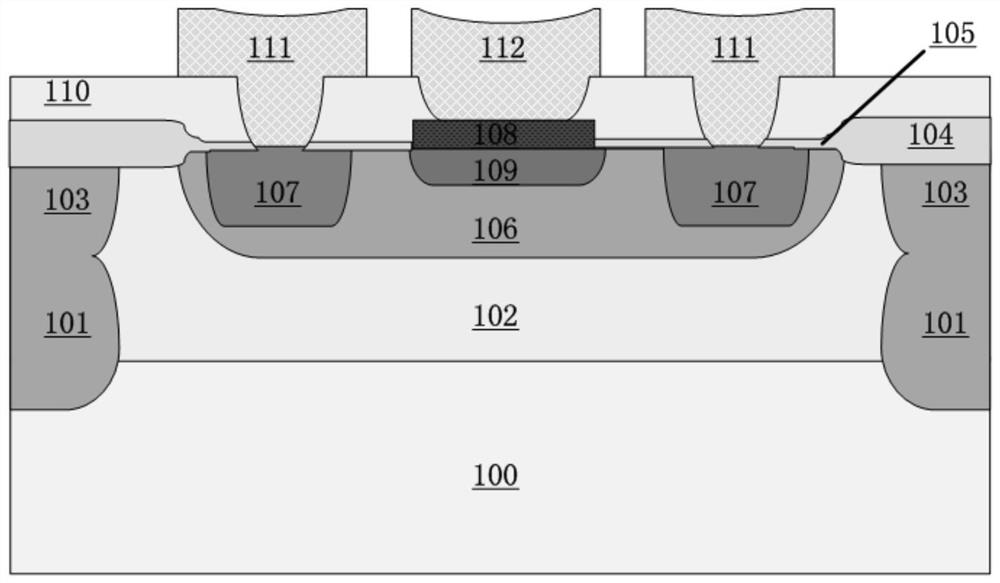

[0078] see Figure 1 to Figure 9 , a polycrystalline self-doped smooth top-gate JFET device, comprising a P-type substrate 100, a P-type buried layer 101, an N-type epitaxial layer 102, a P-type isolation penetration region 103, a field oxygen layer 104, and a pre-oxidation layer 105 , P-type channel region 106, P-type heavily doped source and drain region 107, polycrystalline gate region 108, N-type gate diffusion region 109, TEOS (orthoethyl silicate) metal pre-dielectric layer 110, source and drain first layer metal 111 and gate first layer metal 112 .

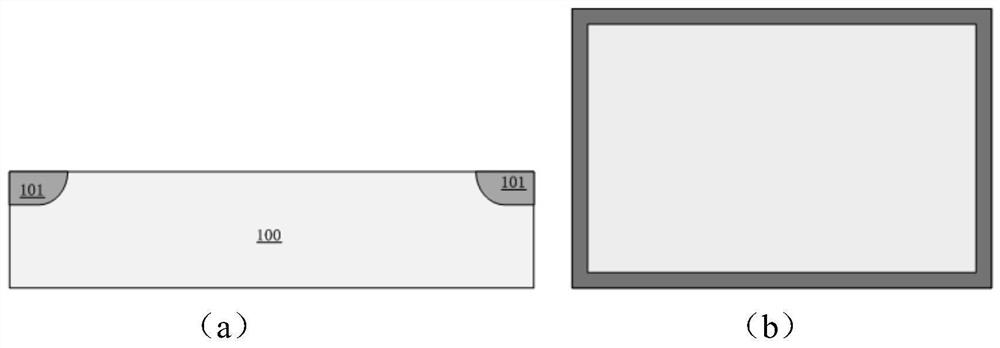

[0079] A P-type buried layer 101 is deposited on both ends of the upper surface of the P-type substrate 100 .

[0080] The materials of the P-type substrate 100 and the N-type epitaxial layer 103 include bulk silicon, silicon carbide, gallium arsenide, indium phosphide or silicon germanium.

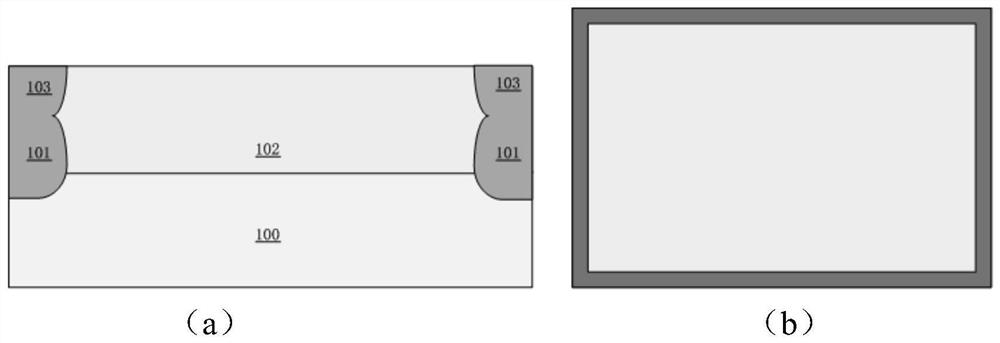

[0081] The N-type epitaxial layer 102 covers the P-type substrate 100 .

[0082] Both ends of the N-type epitaxial layer 102 are i...

Embodiment 2

[0108] A polycrystalline self-doped smooth top-gate JFET device, comprising an N-type substrate 100, an N-type buried layer 101, a P-type epitaxial layer 102, an N-type isolation penetration region 103, a field oxygen layer 104, a pre-oxidation layer 105, N-type channel region 106, N-type heavily doped source and drain regions 107, polycrystalline gate region 108, P-type gate diffusion region 109, TEOS metal front dielectric layer 110, source and drain first layer metal 111 and gate first layer metal 112 .

[0109] An N-type buried layer 101 is deposited on both ends of the upper surface of the N-type substrate 100 .

[0110] The materials of the N-type substrate 100 and the P-type epitaxial layer 103 include bulk silicon, silicon carbide, gallium arsenide, indium phosphide or silicon germanium.

[0111] The P-type epitaxial layer 102 covers the N-type substrate 100 .

[0112] Both ends of the P-type epitaxial layer 102 are in contact with the N-type buried layer 101 .

[0...

Embodiment 3

[0138] Such as figure 1 As shown, a polycrystalline self-doped smooth top-gate JFET device includes a P-type substrate 100, a P-type buried layer 101, an N-type epitaxial layer 102, a P-type isolation penetration region 103, a P-type channel region 106, P-type heavily doped source-drain region 107, polycrystalline gate region 108, N-type gate diffusion region 109, pre-oxidation layer 105, field oxygen layer 104, TEOS metal pre-dielectric layer 110, source-drain first layer metal 111, gate Pole first layer metal 102.

[0139] The P-type buried layer 101 is located at both ends of the upper surface of the P-type substrate 100 .

[0140] The N-type epitaxial layer 102 is located on the P-type substrate 100 , and the N-type epitaxial layer 102 is in contact with the P-type substrate 100 and the P-type buried layer 101 .

[0141] The P-type isolation penetration region 103 is in contact with both ends of the N-type epitaxial layer 102 , and the bottom of the P-type isolation pene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com