Odh complex with on-line mixer unit and feed line cleaning

A combined device and mixer technology, applied in the field of chemical combined devices of ODH, can solve the problems of high cost and regular shutdown of coke by-products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

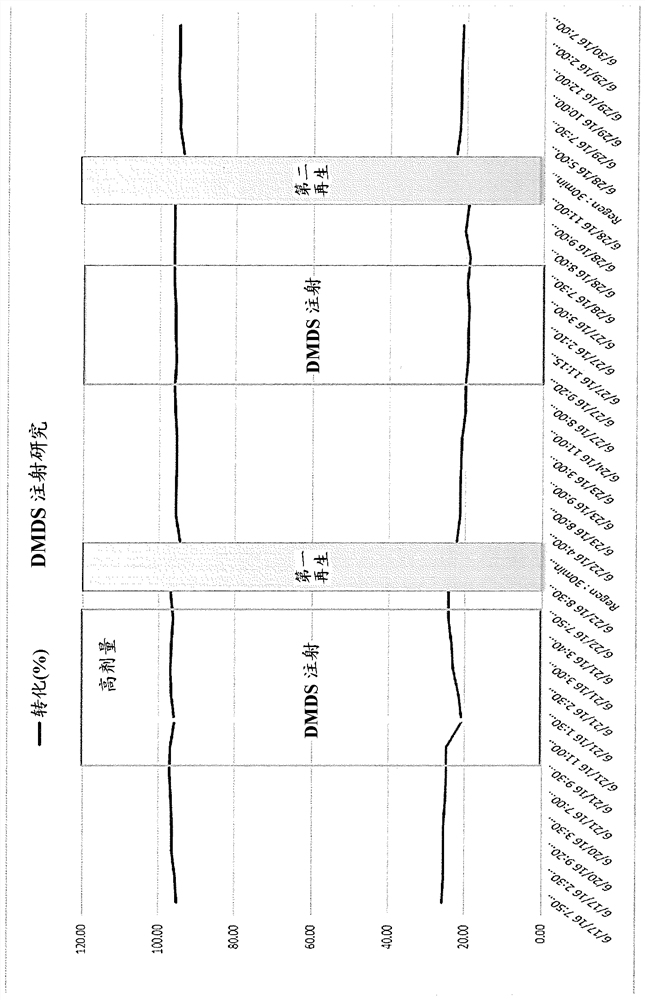

[0220] An effective solvent for dissolving sulfur scale was found in experiments. The following chemicals were experimentally tested:

[0221] 1. Toluene*

[0222] 2. Methanol

[0223] 3. Wash Oil* (Refined Heavy Reformate - Aromatics)

[0224] 4. Heptane

[0225] 5. water

[0226] 6. EnviroSol (citrus based solvent / degreaser)

[0227] 7. Dimethylsulfoxide (DMSO)

[0228] 8. Carbon disulfide (CS2)

[0229] 9. Dimethyl disulfide (DMDS)

[0230] 10. Tert-butyl polysulfide (TBPS)

[0231] CS2 was found to be a good solvent at room temperature for removal of fouling material, however this solvent presents a safety hazard and is very toxic. Also, its effect on the ODH method is unknown.

[0232] Heated toluene was also found to be effective and a safer solvent than CS2. Therefore, the use of heated toluene has been recommended for extreme environments. For example, when a feed vaporizer is blown off, material is pushed into the flare tip where it can accumulate and plug...

Embodiment approach

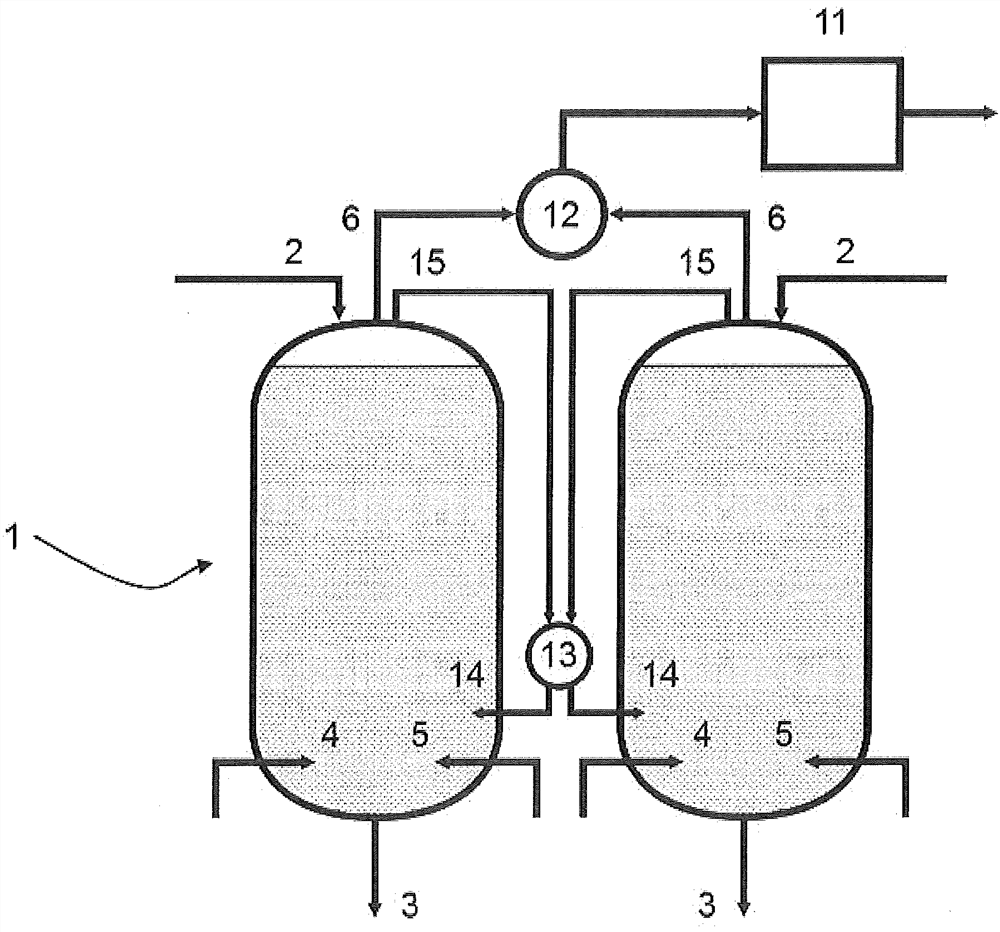

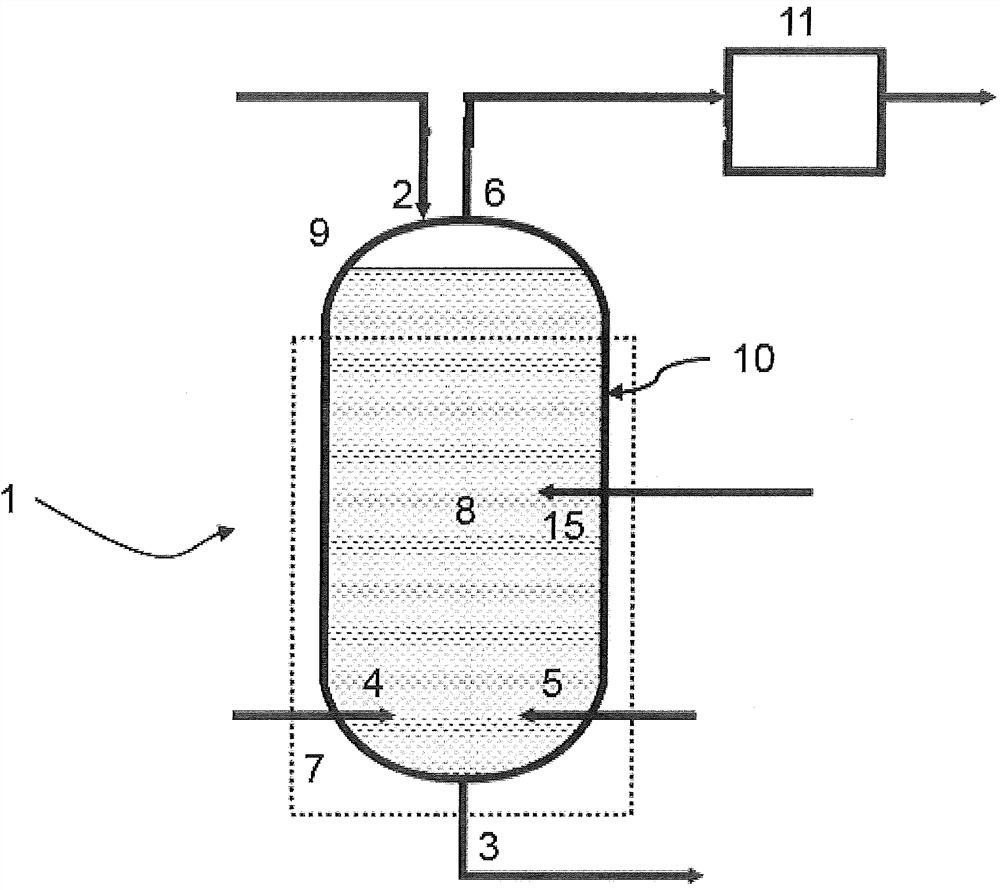

[0245] 1. A chemical complex for the oxidative dehydrogenation of lower alkanes, said chemical complex comprising:

[0246] i) at least two mixers for premixing oxygen-containing gas and lower alkane-containing gas to produce a mixed feedstock stream and additionally comprising a purge circuit; and

[0247] ii) at least one oxidative dehydrogenation reactor;

[0248] wherein said at least two mixers are connected in parallel to said at least one oxidative dehydrogenation reactor such that during normal operation either the first gas mixing unit or the second gas mixing unit is connected to said at least one oxidative dehydrogenation reactor; as well as

[0249] wherein the oxidative dehydrogenation catalyst contained within the at least one oxidative dehydrogenation reactor reacts with the mixed feed stream to produce a product stream comprising the corresponding olefin.

[0250] 2. The chemical complex of embodiment 1, wherein the cleaning circuit comprises a pump, a filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com