High-strength galvanized steel sheet, high-strength member, and manufacturing methods therefor

A technology of galvanized steel sheet and manufacturing method, applied in manufacturing tools, hot-dip plating process, coating, etc., to achieve the effects of excellent strength-ductility, good surface properties, and excellent resistance to hydrogen embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

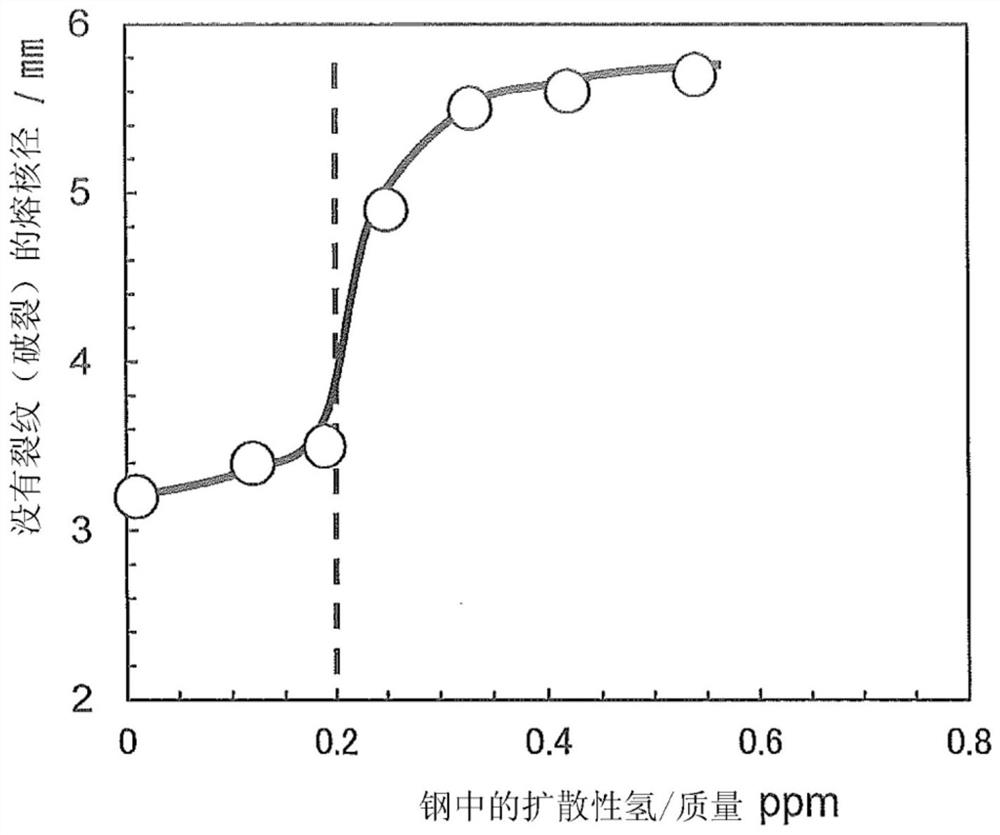

Problems solved by technology

Method used

Image

Examples

Embodiment 1

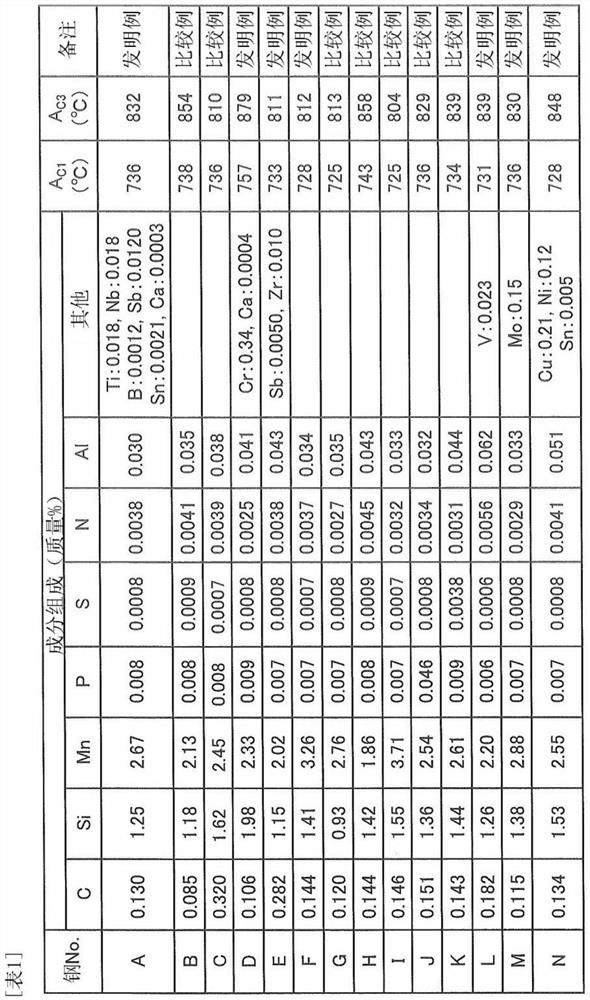

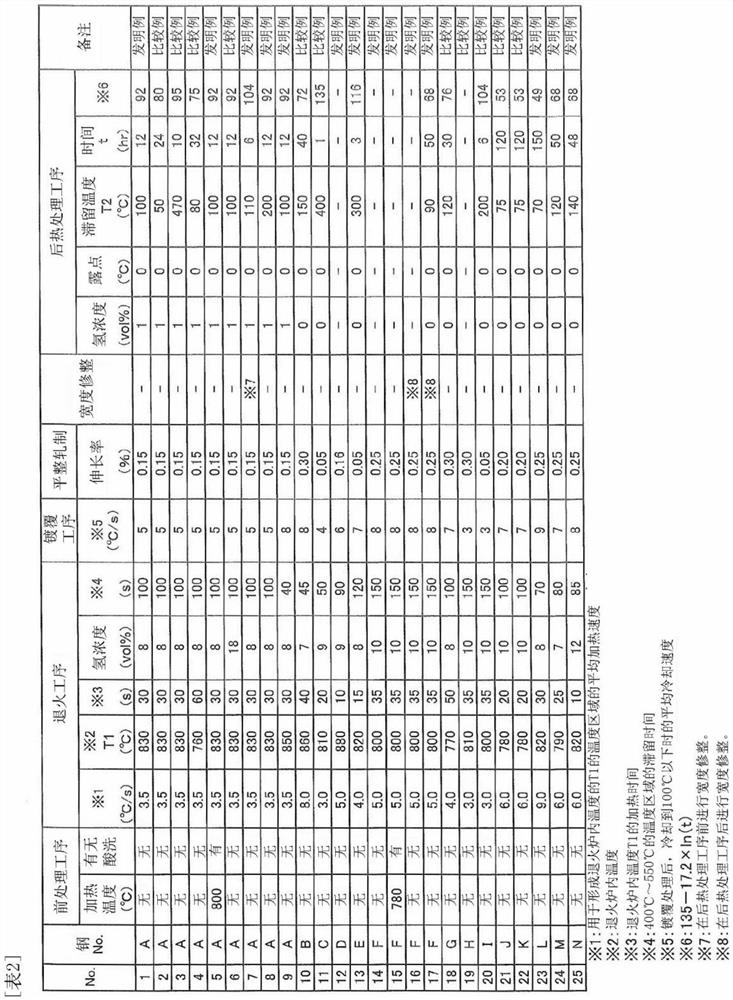

[0146]Molten steel having the component composition of steel A shown in Table 1 was melted in a converter, and a billet was formed by a continuous casting machine. This billet was heated to 1200°C, and a hot-rolled steel coil was formed at a finish rolling temperature of 840°C and a coiling temperature of 550°C. This hot-rolled steel coil was formed into a cold-rolled steel sheet having a cold reduction ratio of 50% and a sheet thickness of 1.4 mm. The cold-rolled steel sheet was heated to 810°C ((A c3 point -10°C) to 900°C), stay for 60 seconds, cool to 500°C, and stay for 100 seconds. Afterwards, galvanizing is carried out to perform alloying treatment, and after plating, it passes through a water bath at a water temperature of 40°C, thereby cooling at a cooling stop temperature of 100°C or lower and an average cooling rate of 3°C / s or higher to produce high-strength steel. Galvanized steel sheet (product sheet). Skin temper rolling was performed after plating, and the el...

Embodiment 2

[0157] Melt molten steel with the composition of steels A to N shown in Table 1 in a converter, use a continuous casting machine to form a billet, heat it to 1200°C, and then carry out hot rolling. The finishing temperature is 910°C, and the coiling temperature is 560°C Form hot-rolled steel coils. Thereafter, a cold-rolled steel coil having a cold reduction rate of 50% and a thickness of 1.4 mm was formed. It was subjected to heating (annealing), pickling (pickling using a pickling solution whose HCl concentration was adjusted to 5 mass%, and the liquid temperature was adjusted to 60° C.), and plating treatment under the various conditions shown in Table 2. , temper rolling, width trimming, and post-heat treatment to manufacture 1.4mm thick high-strength galvanized steel sheets (product sheets). Moreover, it cooled to 100 degreeC or less by passing through the water tank of 50 degreeC of water temperature during cooling (cooling after plating process). In addition, in the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com