Landfill leachate and landfill gas collection system and method

A collection system and landfill gas technology, applied in the fields of landfill technology, pipeline system, waterway system, etc., can solve the problems of easily blocking pipelines, affecting the drainage of landfill gas, blocking horizontal collection tube wells, etc. Pipe blockage, convenient daily maintenance, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

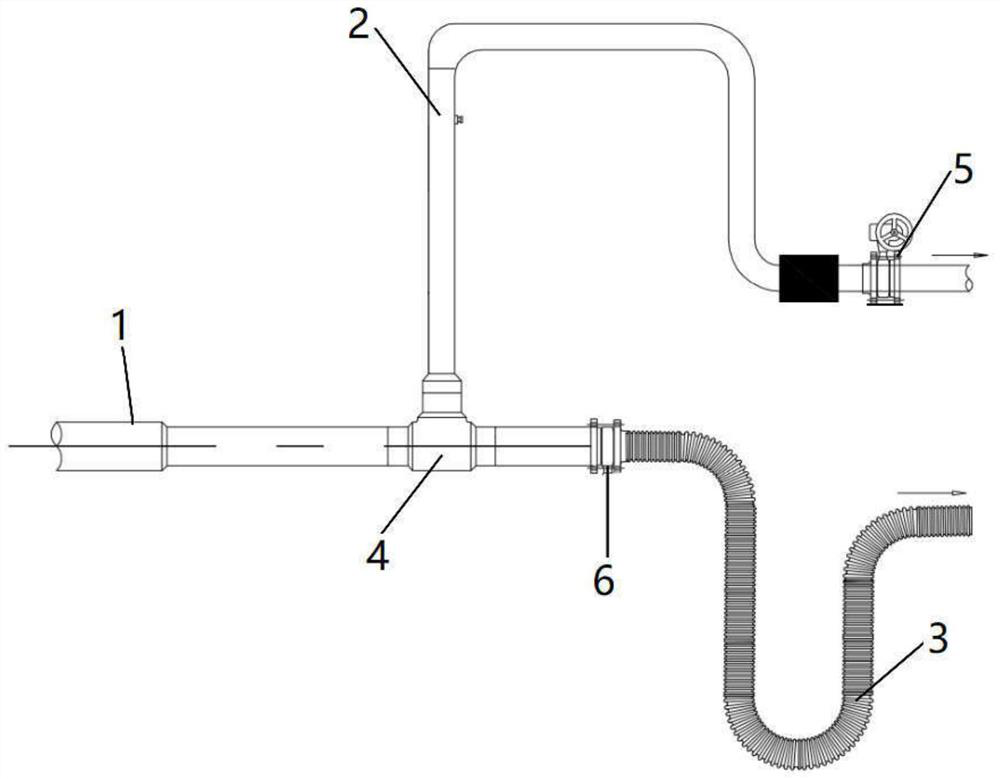

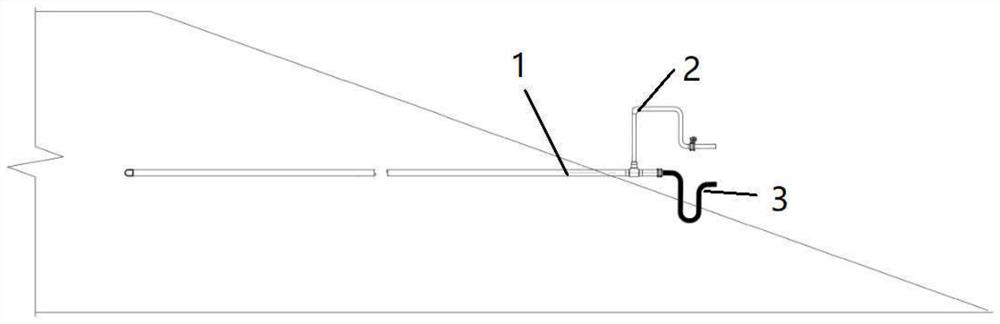

[0027] Such as Figure 1 ~ Figure 2 shown, as Figure 1 ~ Figure 2 As shown, the landfill leachate and landfill gas collection system described in this embodiment includes a first air duct 1, a second air duct 2 and a water duct 3, and the first air duct 1 is inclined relative to the horizontal direction Angle setting, one end of the first air guide pipe 1 extends into the landfill, and the second air guide pipe 2 and the water guide pipe 3 are respectively connected to one end of the first air guide pipe 1 that does not extend into the landfill, The second air guide tube 2 is located between the first air guide tube 1 and the water guide tube 3, and the first air guide tube 1, the second air guide tube 2 and the water guide tube 3 communicate with each other, so The second air guide tube 2 is arranged vertically, and the second air guide tube 2 is connected to a mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap