Treatment system and method for degrading organic matters in fracturing flow-back fluid by using halotolerant bacteria

A fracturing flowback fluid and treatment system technology, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of unstable removal effect and high operating cost of organic matter removal, and reduce labor Labor intensity, convenient management, and the effect of reducing land occupation

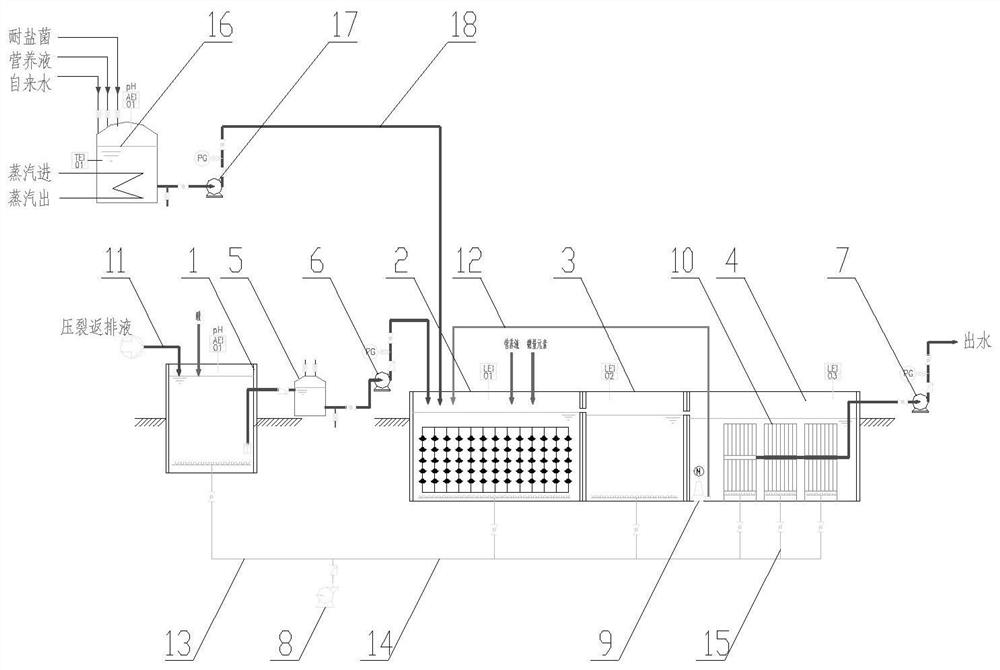

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0032] Taking the fracturing flowback fluid of a block in Sichuan as the research object, the influent CODcr of fracturing flowback fluid sewage is 650mg / L, ammonia nitrogen is 68mg / L, B / C is 0.25, and the salt content is 3.5%.

[0033] The fracturing flowback liquid sewage enters the wastewater regulating tank 1 through the pipeline, and hydrochloric acid is added to adjust the pH at 4 to 6; the effluent from the regulating tank (1) enters the integrated reaction device through the self-priming tank 5, and the wastewater is in the integrated reaction device After successively passing through the contact oxidation tank 2, the aerobic aeration tank 3 and the MBR membrane tank 4, the contact oxidation tank 2 is equipped with elastic fillers, and the filler suspension density is controlled at 70% of the tank volume; the fan 8 is connected with the contact oxidation tank 2, the aerobic aeration tank The aeration pipes at the bottom of the gas tank 3 and the MBR membrane tank 4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com