Plasma fabric modification treatment device

A processing device, plasma technology, applied in physical processing, liquid/gas/steam textile material processing, textile material processing and other directions, can solve problems such as single function, reduced efficiency, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

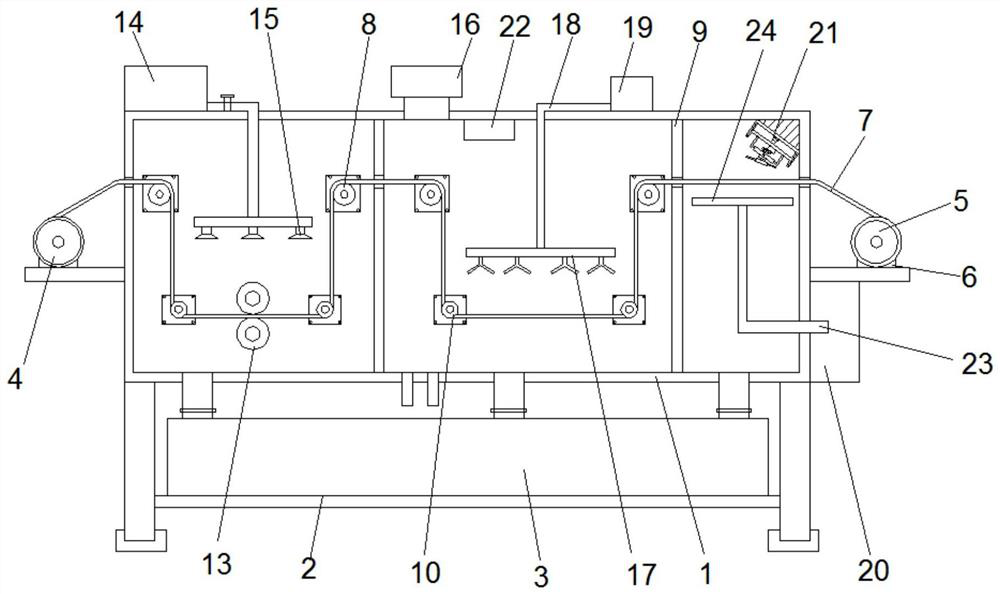

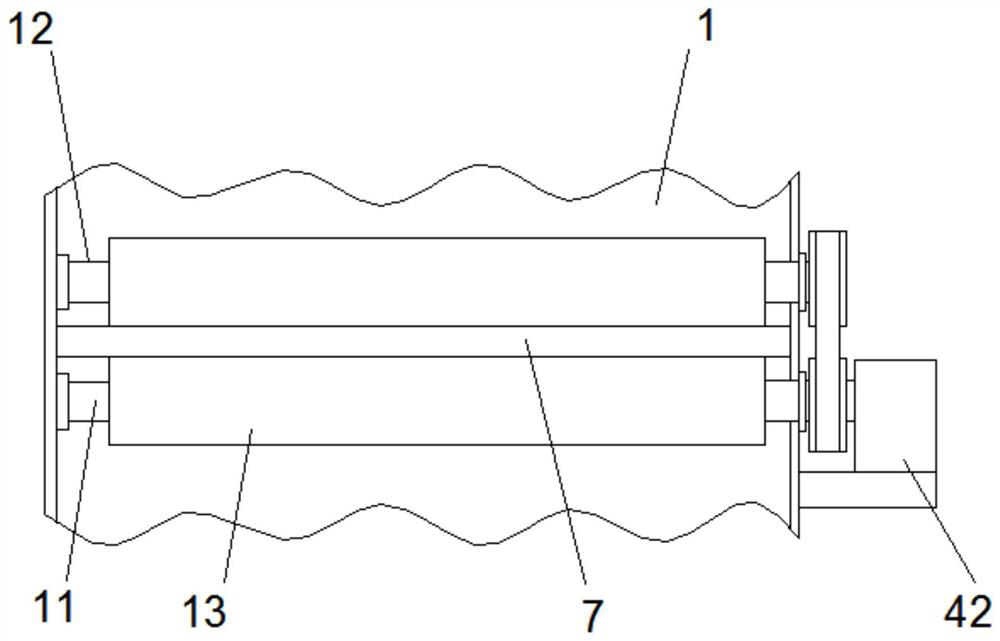

[0026] see Figure 1-4A plasma fabric modification treatment device according to an embodiment of the present invention, comprising a treatment housing 1, the bottom of the treatment housing 1 is symmetrically fixed with support legs, and a support seat 2 is fixed between the support legs, The support base 2 is provided with a recovery mechanism 3, and both sides of the processing housing 1 are fixedly provided with mounting seats, and the mounting seats are respectively equipped with a feeding drum 4 and a receiving drum 5. The drum 4 and the middle part of the receiving drum 5 are provided with a movable shaft, and one end of the movable shaft is connected with the output end of the motor one 6, and the motor one 6 is fixed on the mounting seat, and the feeding drum 4 A fabric 7 is connected between the receiving drum 5, and a cleaning chamber, an airtight processing chamber and a drying chamber are sequentially arranged inside the processing housing 1 from left to right, th...

Embodiment 2

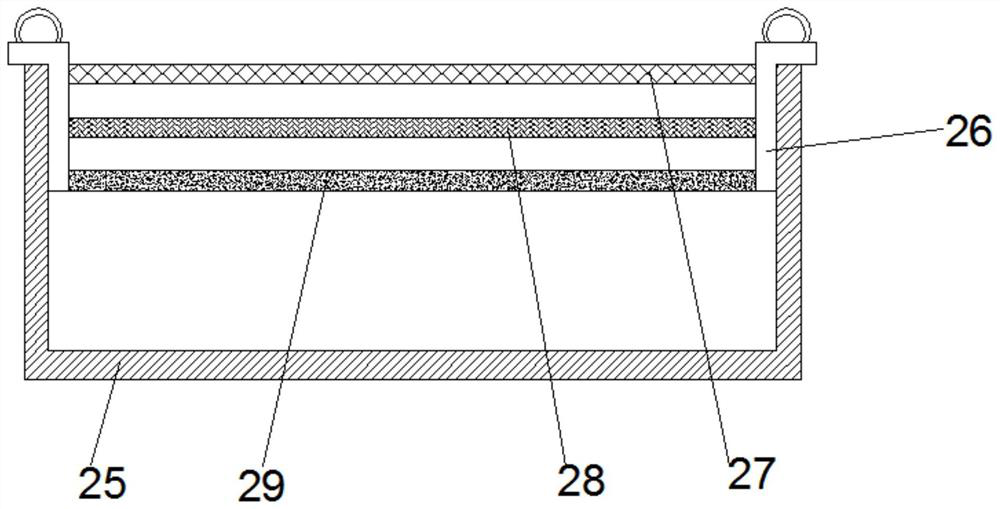

[0028] see Figure 1-4 , for the corner roller 8, both the corner roller 8 and the guide roller 10 are fixedly connected to the processing housing 1 through a mounting plate. For the water inlet pipeline, valves are installed on the water inlet pipeline, the first water outlet, the second water outlet, and the third water outlet, and the water flow is controlled by the valves. For the recovery mechanism 3, the recovery mechanism 3 includes a recovery box body 25, the inside of the recovery box body 25 is provided with a filter basket 26, and the filter basket 26 is sequentially installed with an activated carbon adsorption layer 27, coarse Filter mesh layer 28 and fine filter mesh 29. For the filter basket 26, the tops of both ends of the filter basket 26 are fixedly provided with pull rings, and the treated water can be recovered by being provided with a recovery box 25, and then passed through the activated carbon adsorption layer on the filter basket 26. 27. The coarse fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com