High-precision high-temperature-resistant nuclear-radiation-resistant valve position acquisition device

A collection device and high-temperature-resistant technology, which is applied in the direction of valve device, valve details, valve shell structure, etc., can solve the problem of inability to realize fault diagnosis and eliminate the need for intelligent control, inability to realize information collection at any position of the valve, and restrict the upgrading of valve intelligent functions Development and other issues, to achieve low risk of medium leakage, compact structure, and reduce the effect of leakage risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

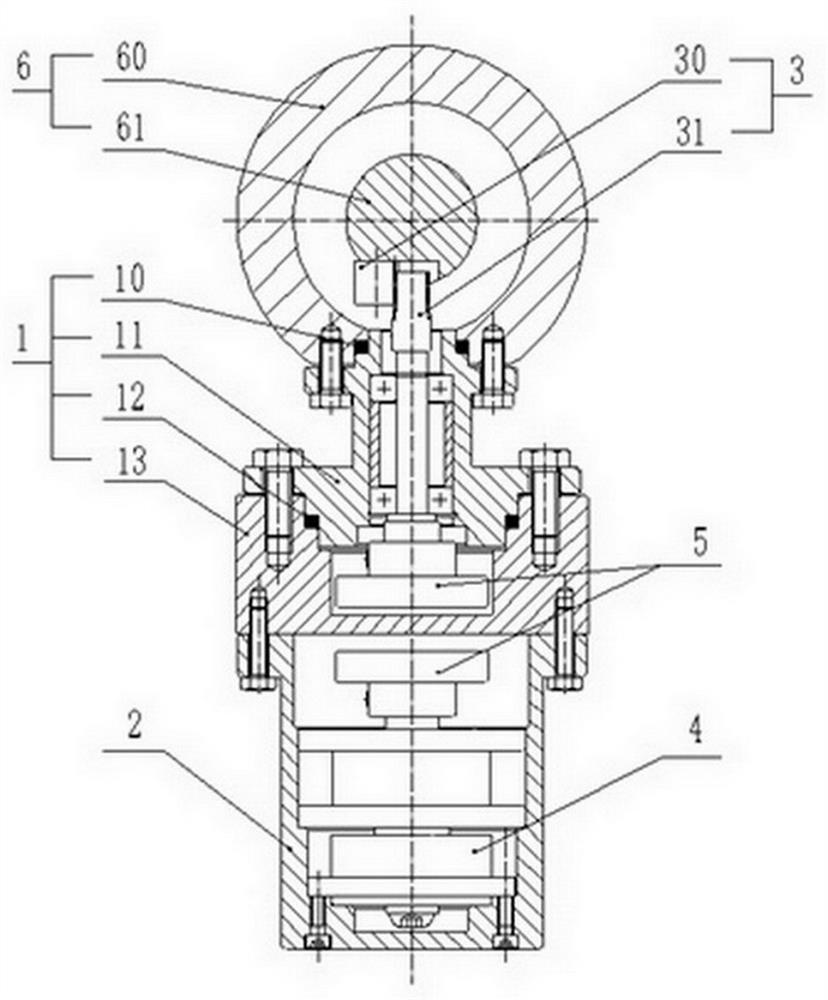

[0028] The invention provides a high-precision high-temperature nuclear radiation-resistant valve position acquisition device, which is characterized in that it is used in conjunction with a valve actuator, especially a high-temperature-resistant and nuclear-radiation-resistant shielded valve actuator, to achieve high temperature and nuclear radiation environments. The position of the valve stem is accurately collected and detected in real time for the whole stroke. The invention is directly installed and connected to the valve actuator, and the pressure medium is isolated through the sealing shell, so that the valve position acquisition device is not affected by the type and pressure of the medium in the valve. Accurate detection of the valve position is realized by directly collecting the position information of the valve stem within the working range of the full stroke. Through the non-contact motion transmission of magnetic transmission elements, the use of dynamic seals i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com