Sandwich structure composite material and preparation method and application thereof

A composite material and sandwich technology, used in structural parts, chemical instruments and methods, carbon compounds, etc., can solve problems such as electrical conductivity damage, and achieve the effects of improving stability, improving ion transport capacity, and increasing electrochemical reaction area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

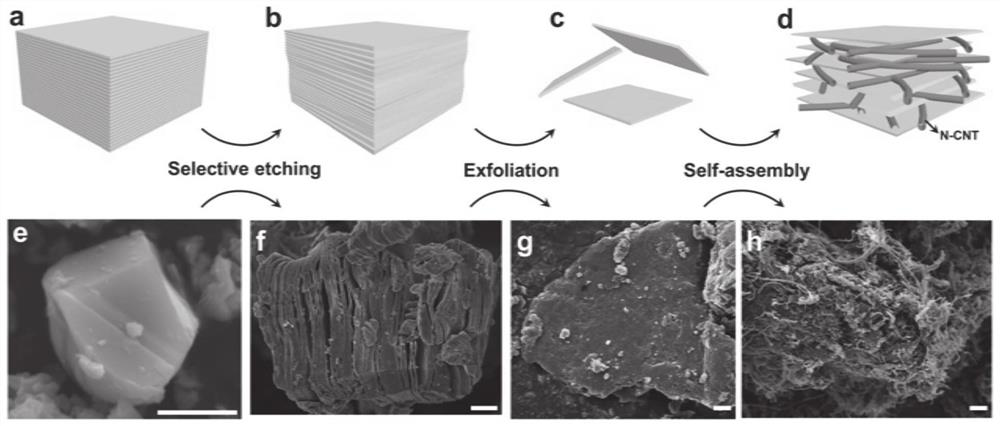

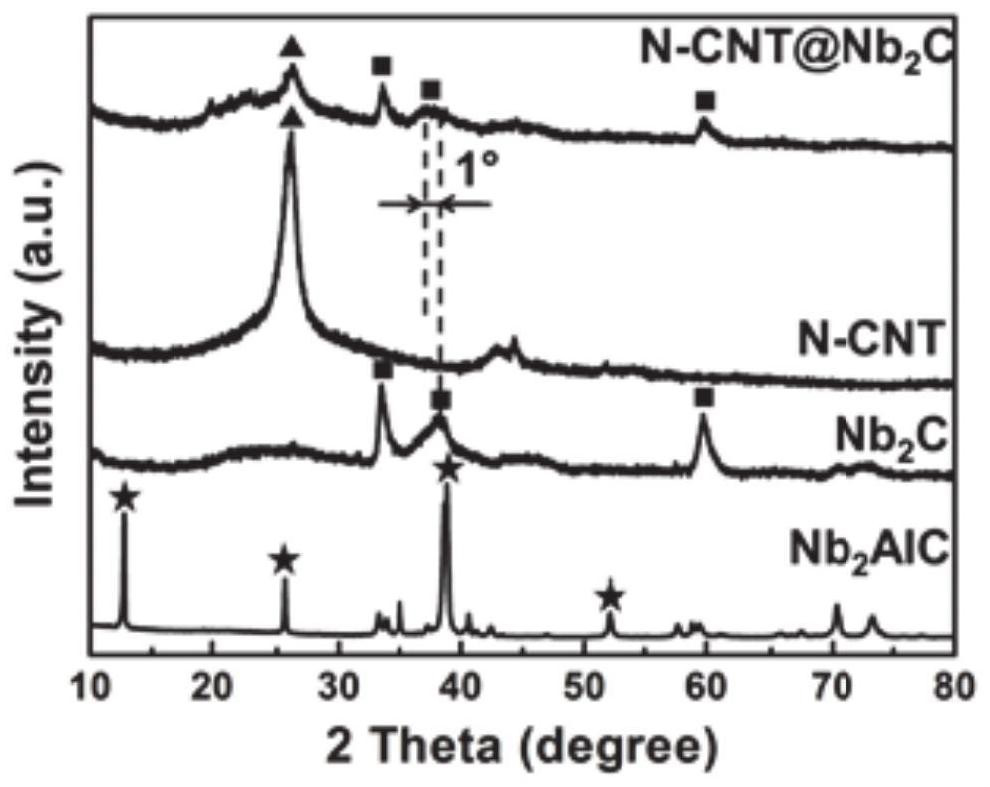

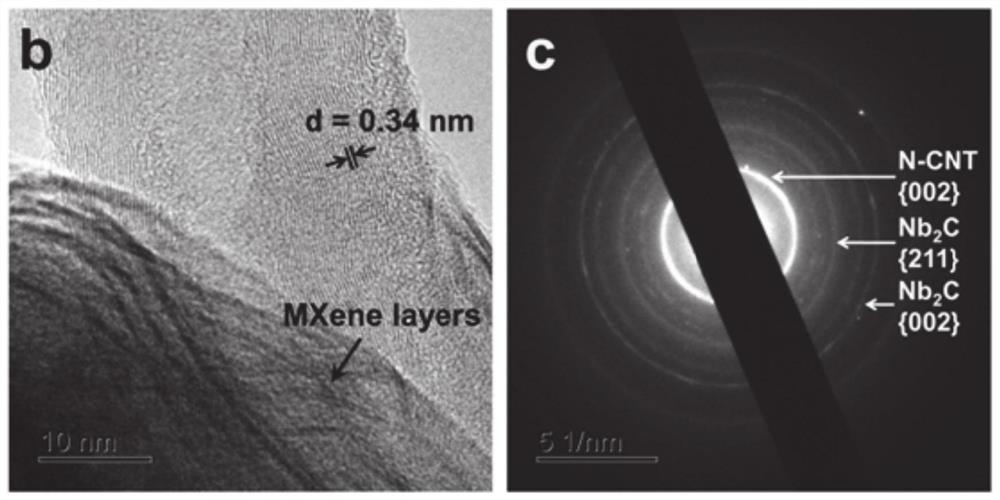

[0048] 2g of Nb 2 AlC was crushed into smaller particles by ball milling for 30 minutes and selectively etched with 40% HF, and the mixture was stirred for 24 hours and centrifuged at a speed of 4000 rpm. Collect the precipitate and wash repeatedly until the pH value of the supernatant is 6-7. Nb was obtained after drying 2 c. Then Nb 2 C was dispersed into a large amount of deionized water and argon gas was continuously injected for ultrasonic dispersion, and the temperature was kept at 25 °C. The solution was then centrifuged at 3500 rpm for 1 hour. Collect the upper liquid state, that is, MXeneNb with fewer layers 2 C colloidal solution. 1.55 mg of nitrogen-doped carbon nanotubes (N-CNT) prepared by chemical vapor deposition and 0.25 g of cetyltrimethylammonium bromide (CTAB) were mixed into 30 ml of deionized water and stirred and ultrasonically dispersed for 30 min. Then 3 mL of 5 mg / mL Nb 2 C colloidal solution was added dropwise to the mixture and sonicated for ...

Embodiment 2

[0053] 2g of Nb 2 AlC was crushed into smaller particles by ball milling for 30 minutes and selectively etched with 40% HF, and the mixture was stirred for 24 hours and centrifuged at a speed of 4000 rpm. Collect the precipitate and wash repeatedly until the pH value of the supernatant is 6-7. Nb was obtained after drying 2 c. Then Nb 2 C was dispersed into a large amount of deionized water and argon gas was continuously injected for ultrasonic dispersion, and the temperature was kept at 25 °C. The solution was then centrifuged at 3500 rpm for 1 hour. Collect the upper liquid state, that is, MXeneNb with fewer layers 2 C colloidal solution. 1.55 mg of nitrogen-doped carbon nanotubes (N-CNT) prepared by chemical vapor deposition and 0.25 g of cetyltrimethylammonium bromide (CTAB) were mixed into 27 ml of deionized water and stirred and ultrasonically dispersed for 30 min. Then 3 mL of 5 mg / mL Nb 2 C colloidal solution was added dropwise to the mixture and sonicated for ...

Embodiment 3

[0055] 2g of Nb 2 AlC was crushed into smaller particles by ball milling for 30 minutes and selectively etched with 40% HF, and the mixture was stirred for 24 hours and centrifuged at a speed of 4000 rpm. Collect the precipitate and wash repeatedly until the pH value of the supernatant is 6-7. Nb was obtained after drying 2 c. Then Nb 2 C was dispersed into a large amount of deionized water and argon gas was continuously injected for ultrasonic dispersion, and the temperature was kept at 25 °C. The solution was then centrifuged at 3500 rpm for 1 hour. Collect the upper liquid state, that is, MXeneNb with fewer layers 2C colloidal solution. 1.8 mg of nitrogen-doped carbon nanotubes (N-CNT) prepared by chemical vapor deposition and 0.25 g of cetyltrimethylammonium bromide (CTAB) were mixed into 30 ml of deionized water and stirred and ultrasonically dispersed for 30 min. Then 3 mL of 5 mg / mL Nb 2 C colloidal solution was added dropwise to the mixture and sonicated for 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com