Production method of rice noodle special flour for precise rice blending and rice noodle special flour

A special flour and rice noodle technology, applied in food science and other directions, can solve problems such as the inability to guarantee the stability of raw materials and processed products for rice noodle production, the deterioration of early indica rice varieties, and the frequent variety changes, so as to improve the standardization of production, reduce water consumption, The effect of ensuring product quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

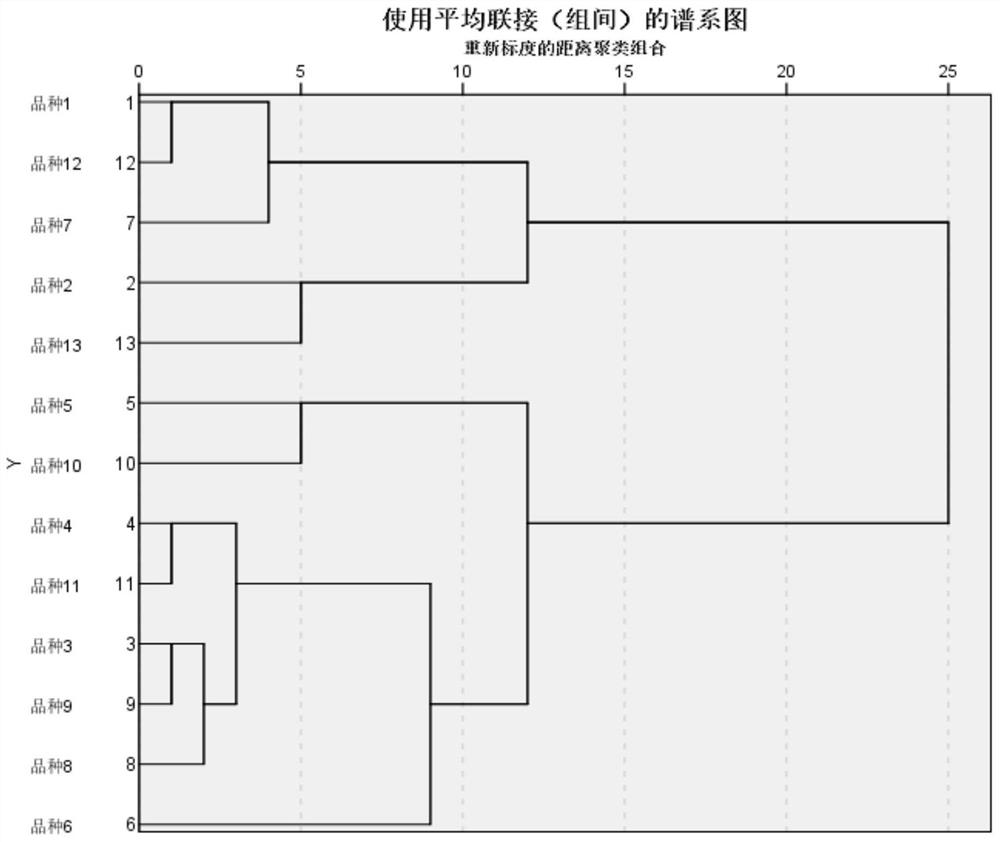

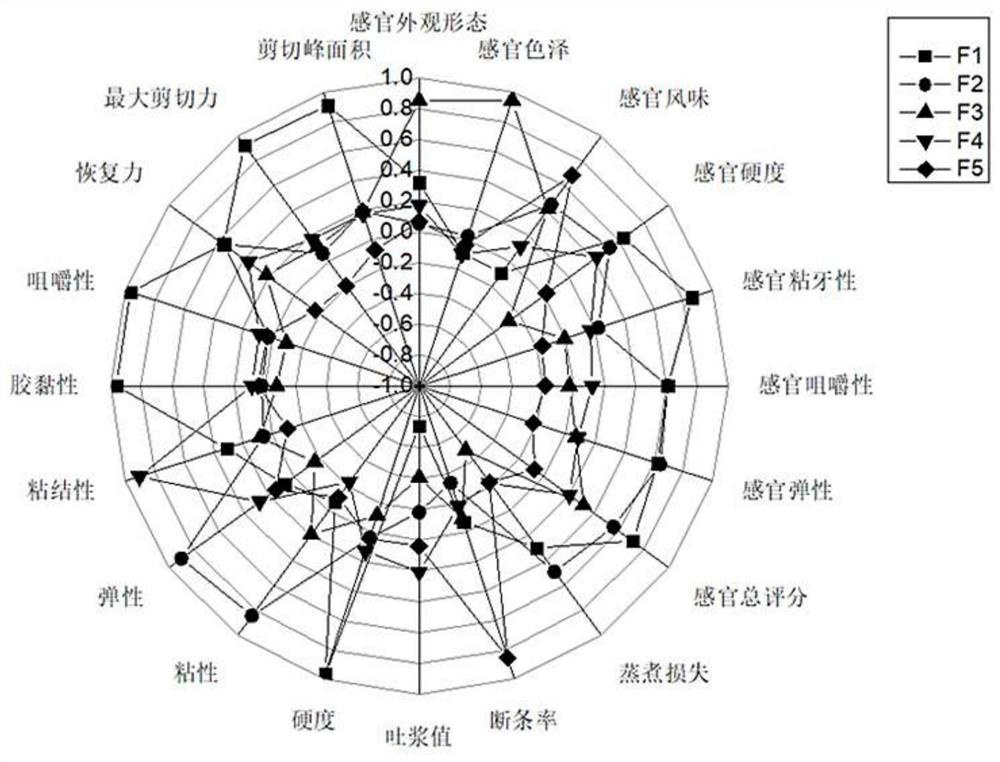

[0045] Embodiment 1: establish the screening method for rice flour special powder

[0046] (1) Collect samples of 13 rice varieties that are widely planted and popularized in the country; measure their starch content, amylose content, amylopectin content, straight branch ratio, protein content, fat content, gel consistency, solubility, penetrating force, peak value Viscosity, valley value viscosity, attenuation value, final viscosity value, retrogradation value, peak time, gelatinization temperature, particle size, whiteness rice 18 indicators.

[0047] (2) Adopt the widely used powder pressing process in industrialization, and optimize the following process flow through preliminary experiments: rice → rice washing, soaking rice → draining → semi-dry crushing → twin-screw extrusion → high temperature aging → rice noodles;

[0048]Wherein, the moisture content of the semi-dry pulverized rice flour is 33%-38%; the screw speed is 95r / min; the extrusion gelatinization temperature ...

Embodiment 2

[0073] Embodiment 2: prepare rice noodle special powder

[0074] Step 1: Subject the rice samples to be evaluated to husking, rice milling, color sorting, etc., with a processing accuracy of above grade 3, and measure the total starch content, amylose content, amylopectin content, amylopectin ratio, final viscosity, retrogradation Value, disintegration value, whiteness and other key indicators;

[0075] Step 2: Determining that the starch content is 81.83g / 100g, the amylose content is 25.50g / 100g, the amylopectin content is 55.52g / 100g, the straight branch ratio is 0.46, the final viscosity is 3486cP, the retrogradation value is 1732cP, the collapse The solution value is 531cP, and the whiteness is 77.9;

[0076] Step 3: if the rice raw material index is within the range specified in step (2), proceed to the next step;

[0077] Step 4: Wash the rice, remove the sand, soak at a constant temperature of 25°C for 12 hours, and drain.

[0078] Step 5: using semi-dry air-cooled f...

Embodiment 3

[0085] Step 1: Subject the rice samples to be evaluated to husking, rice milling, color sorting, etc., with a processing accuracy of above grade 3, and measure the total starch content, amylose content, amylopectin content, amylopectin ratio, final viscosity, retrogradation Value, disintegration value, whiteness and other key indicators.

[0086] Step 2: Measure the starch content of 83.82g / 100g, amylose content of 22.81g / 100g, amylopectin content of 56.01g / 100g, straight-branch ratio of 0.40, final viscosity of 2540cP, retrogradation of 1557cP, disintegrate The value is 1205cP, and the whiteness is 75.1.

[0087] Step 3: The rice raw material index is not within the specified range, so it is not suitable for use as a raw material for rice noodles alone. It needs to be compounded, and the method of compounding is used to select another rice: the starch content is 78.83g / 100g, the amylose content is 24.81g / 100g, the amylopectin content is 54.01g / 100g, and the amylopectin ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com