Polyurethane glue preparation process

A technology of polyurethane glue and preparation process, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., and can solve problems such as insufficient mixing, time-consuming and labor-intensive manual mixing, low fusion speed and fusion efficiency of polyurethane glue, etc. , to achieve the effects of improving the preparation efficiency, accelerating the filtration process, accelerating the mixing and fusion speed and fusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

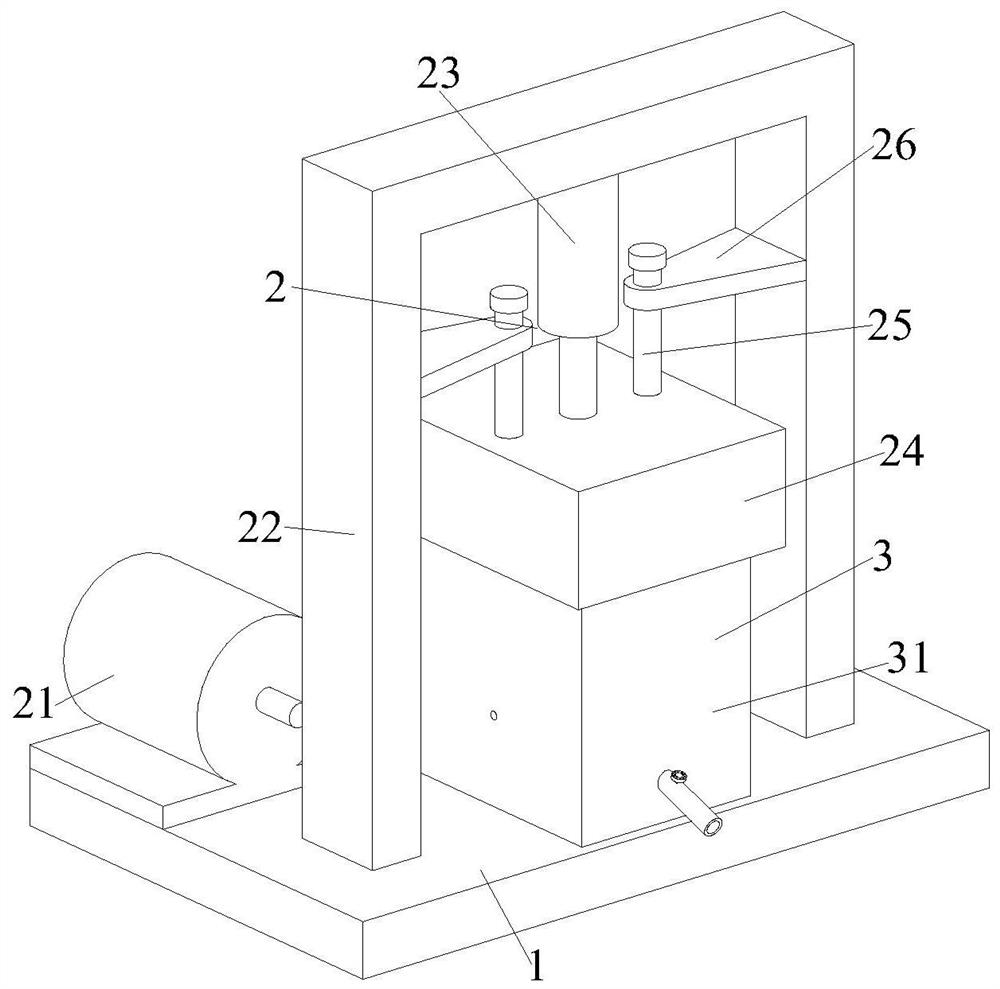

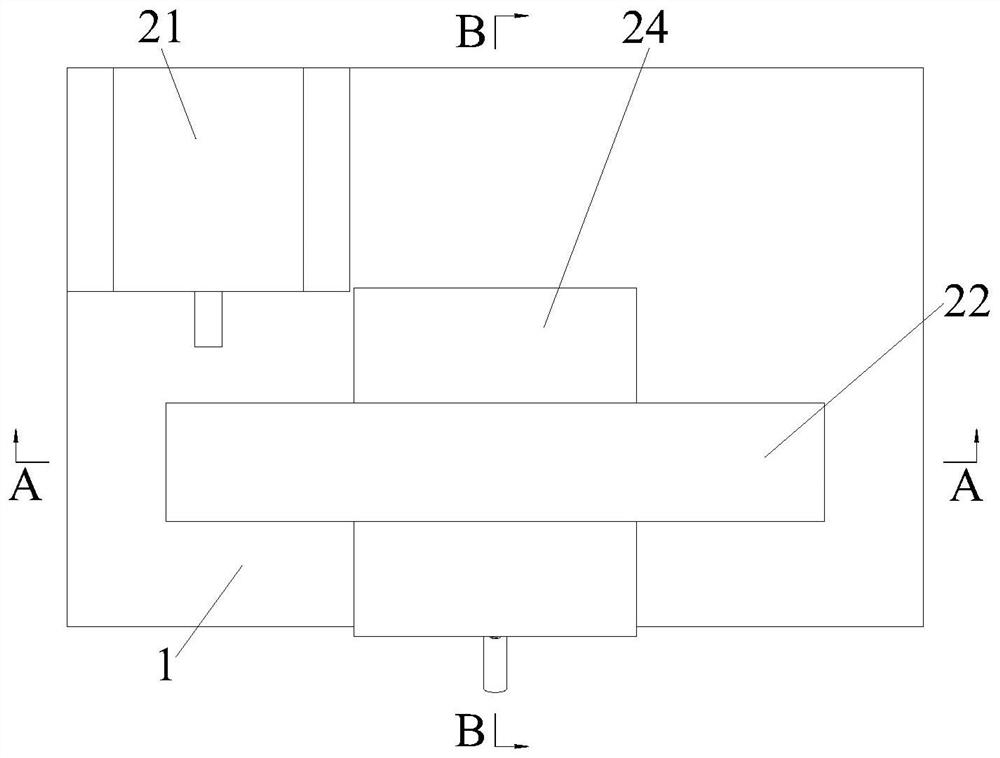

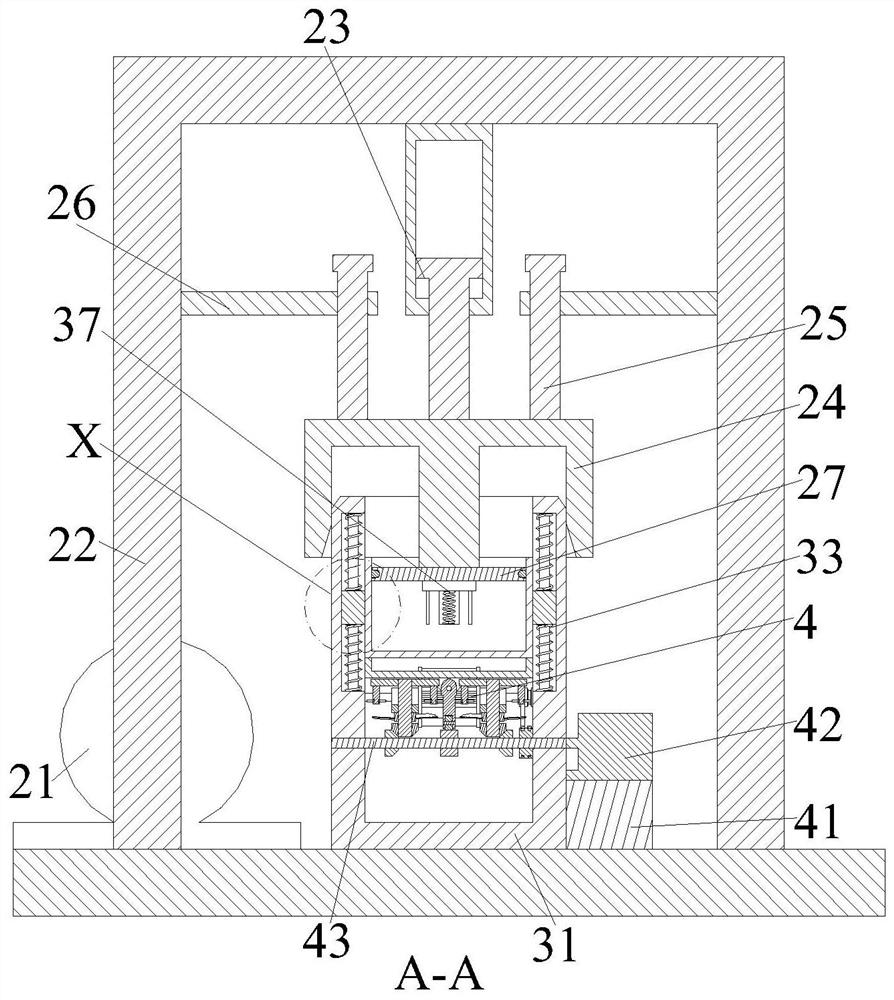

[0036] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

[0037] A preparation process of polyurethane glue, the specific preparation process is as follows:

[0038]S1. Equipment inspection: check the equipment before using the polyurethane glue production equipment to make polyurethane glue;

[0039] S2. Gluing treatment: After the equipment inspection is completed, the polyurethane glue to be filtered is manually placed in the screening device 3, so that the screening device 3 performs screening processing on the polyurethane glue to be filtered;

[0040] S3. Stirring treatment, after the screening is completed, the filtered glue falls to the stirring device 4, so that the stirring device 4 performs stirring treatment on the filtered glue;

[0041] S4. Quality inspection and blanking: After the mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com