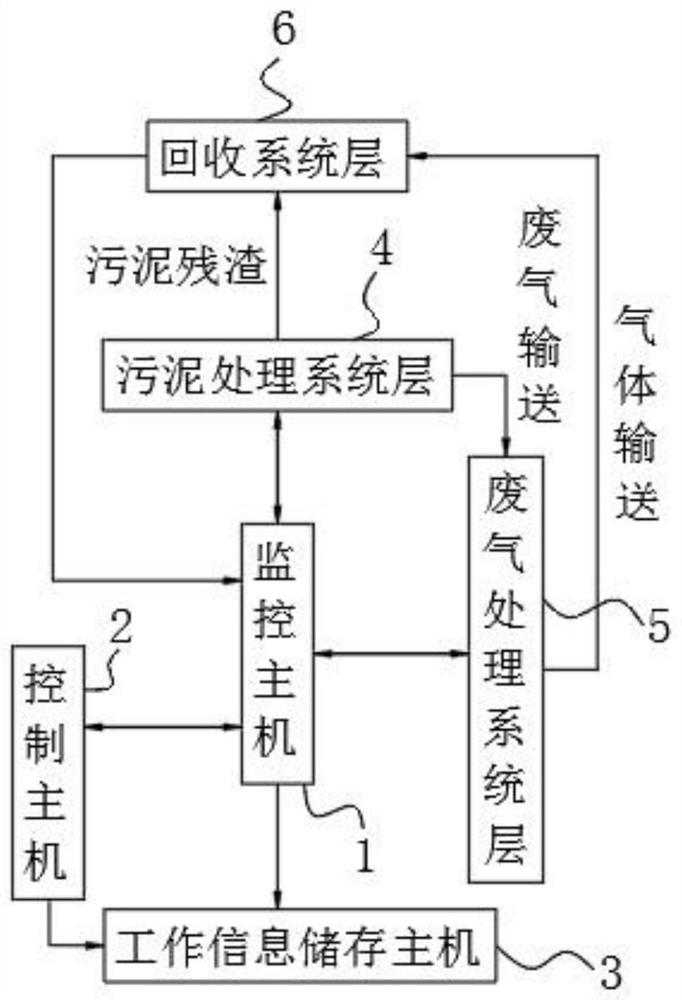

Sludge waste gas comprehensive treatment system and operation method thereof

A comprehensive treatment and sludge treatment technology, applied in gas treatment, dehydration/drying/concentrated sludge treatment, combustion methods, etc., can solve problems such as environmental pollution, harmful gas overflow, inconvenient equipment monitoring, etc., to improve treatment quality , to avoid the effect of polluting the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Step 1: Start the monitoring host 1, the control host 2 and the work information storage host 3 to monitor the relevant information of the system, and record the working information and monitoring information of each device in the system through the information receiving module 102 inside the monitoring host 1, Subsequently, the work information and monitoring information are converted to log mode by the work log generation module 103 and the processing information generation module 104, and then the relevant information is transmitted to the control host 2 by the log transmission module 105 and the log receiving module 21, and the staff passes through the control host 2 monitor the system;

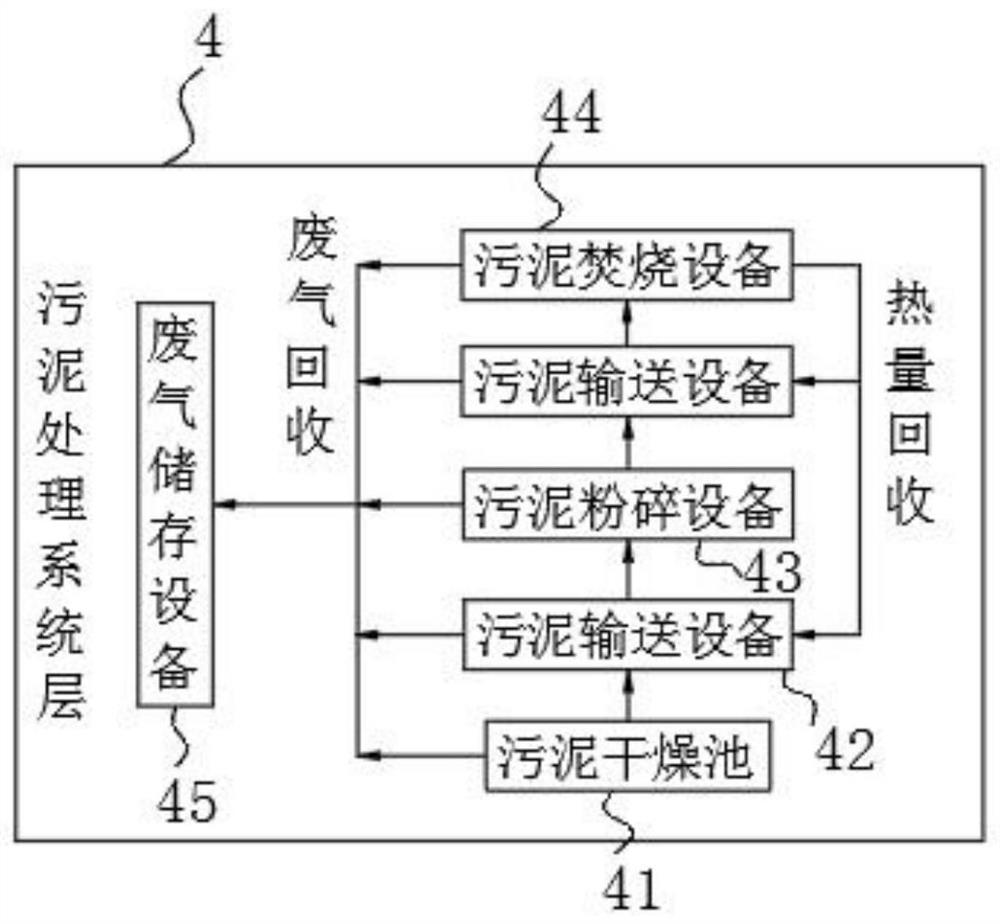

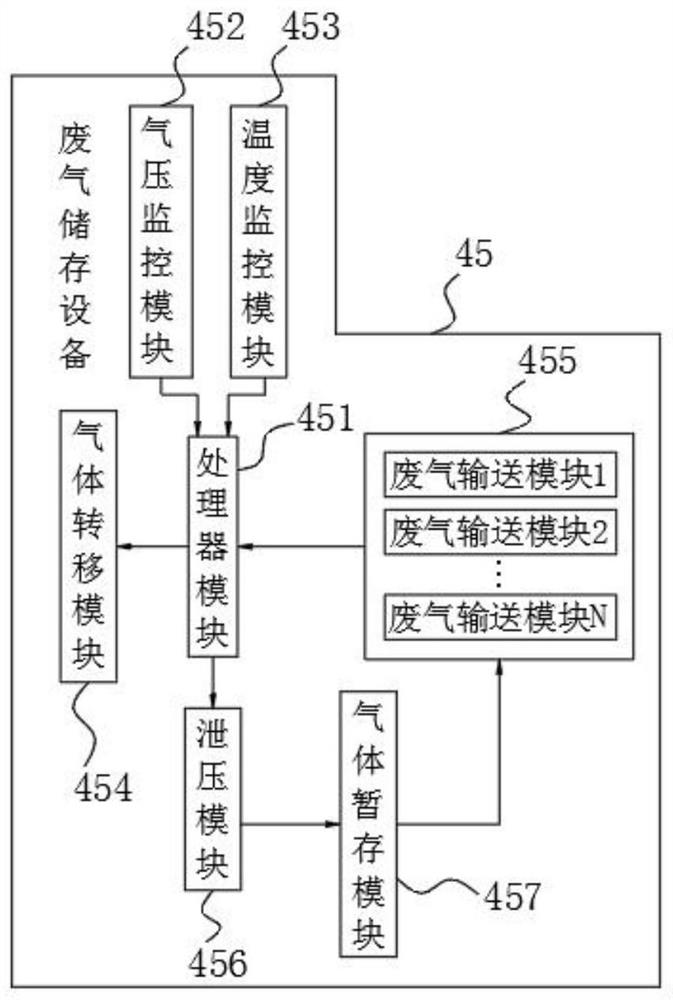

[0048] Step 2: Treat the sludge through the sludge drying tank 41, the sludge crushing equipment 43 and the sludge incineration equipment 44, and the waste gas generated during the transportation and processing of the sludge is collected into the waste gas storage device 45 through ...

Embodiment 2

[0052] Step 1: Start the monitoring host 1, the control host 2 and the work information storage host 3 to monitor the relevant information of the system, and record the working information and monitoring information of each device in the system through the information receiving module 102 inside the monitoring host 1, Subsequently, the work information and monitoring information are converted into a log mode by the work log generation module 103 and the processing information generation module 104, and then the relevant information is transmitted to the control host 2 by the log transmission module 105 and the log reception module 21, and the staff passes through the control host 2 monitor the system;

[0053] Step 2: Treat the sludge through the sludge drying tank 41, the sludge crushing equipment 43 and the sludge incineration equipment 44, and the waste gas generated during the transportation and processing of the sludge is collected into the waste gas storage device 45 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com