Combined dust removal device for continuous casting flame cutting machine and application thereof

A dust-removing device and a combined technology, which are applied in the directions of combined devices, smoke removal, cleaning methods and utensils, etc., can solve the problems of inability to deal with different dust-removing conditions, damage to workers and the environment, and incomplete dust-removal, and achieve a simple and efficient structure. , Complete dust removal, easy to deal with the effect of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

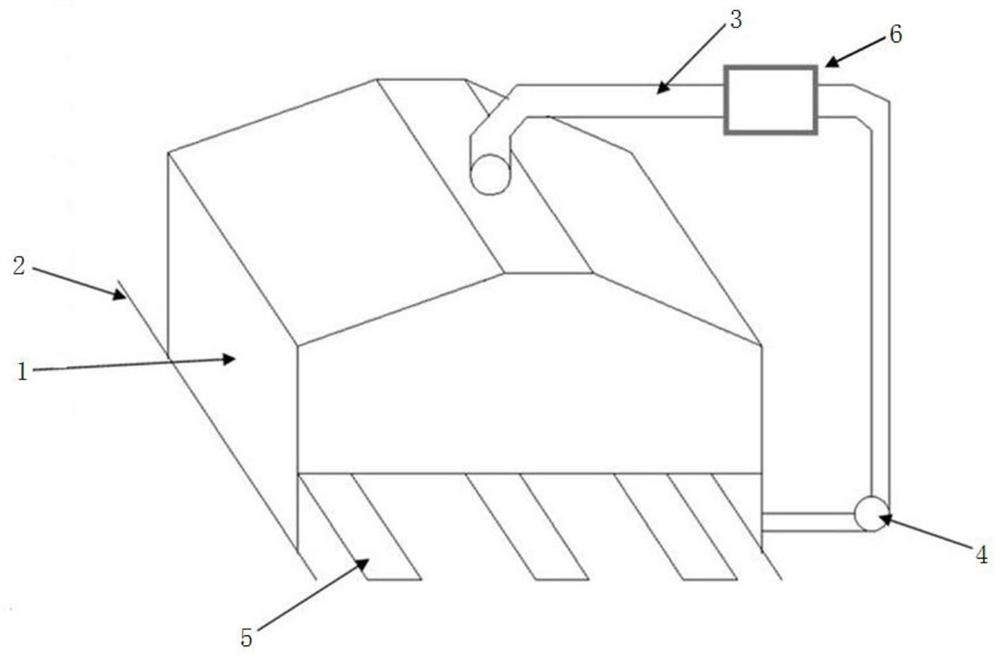

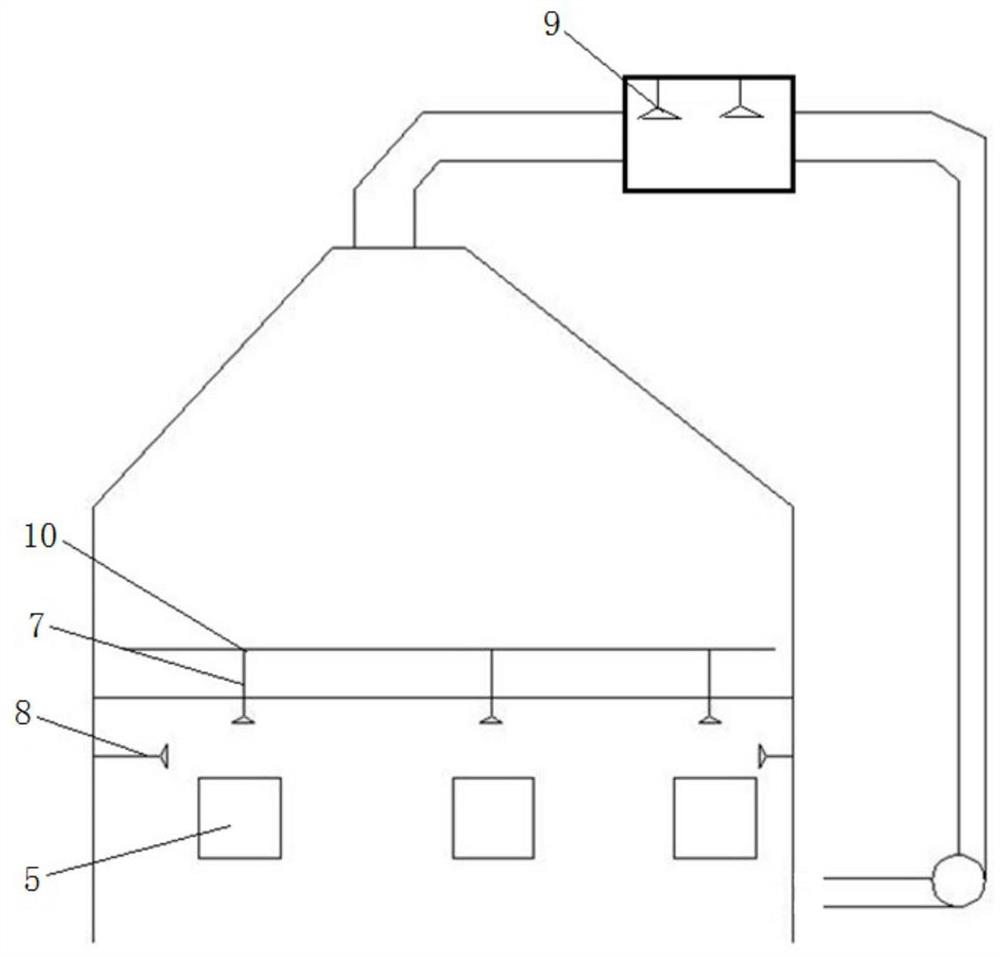

[0030] like Figure 1-2 As shown, this embodiment provides a combined dust removal device for a continuous casting torch cutter, including a dust removal cover 1, which is slidably arranged on slide rails 2 on both sides of the torch cutter; the lower side of the dust removal cover 1 is arranged There is a steel billet 5; one end of the air pipe 3 is connected to the upper side of the dust removal cover 1, and the other end of the air pipe 3 is connected to the fan 4, and a filter 6 is arranged on the air pipe 3 between the fan 4 and the dust removal cover 1; a filter nozzle is arranged in the filter 6 9. A dust removal assembly is arranged inside the dust removal cover 1, and the dust removal assembly is used for dust removal.

[0031] Wherein, the dust removal assembly includes an atomization dust removal assembly and a water curtain assembly; wherein the atomization dust removal assembly includes a support frame 10 and a water mist nozzle 7, the support frame 10 is horizont...

Embodiment 2

[0034] A combined dust removal device for a continuous casting torch cutter, the structure of which is the same as that of Embodiment 1, except that the number of the water mist nozzles 7 is 20.

Embodiment 3

[0036] A kind of working method of the combined type dedusting device that is used for continuous casting fire cutter, adopts the scheme described in embodiment 1, comprises the following steps:

[0037] (1) When the steel billet reaches the working area of the fire cutter in the dust cover, the fire cutter performs the billet fire cutting;

[0038] (2) When the steel billet is cut by fire, the fan and filter nozzle are turned on to extract the particulate smoke from the dust removal hood;

[0039] (3) According to different steel types and the amount of dust, selectively open the water mist nozzle, or open the water mist nozzle and water curtain nozzle at the same time, to spray and reduce dust in the working area; that is, when the dust volume is large, the water mist can be turned on Nozzle, if the amount of dust is larger, the water mist nozzle and water curtain nozzle can be opened at the same time;

[0040] (4) After the billet fire cutting is completed, turn off the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com