Method and structure for improving strength of glass

A glass and strength technology, which is applied to cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of low electromagnetic wave transmission attenuation performance, glass strength decline, and limited glass strength improvement, etc., to achieve light and shadow scenes Good deep feeling, improve compressive strength, and enhance the effect of brilliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the description of the following embodiments is used to help understand the invention, but does not constitute a limitation to the invention.

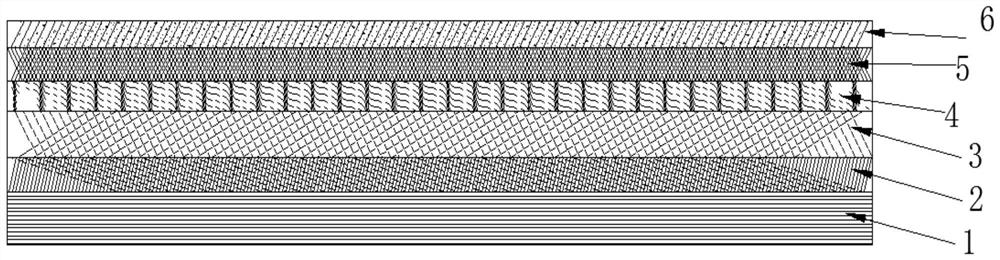

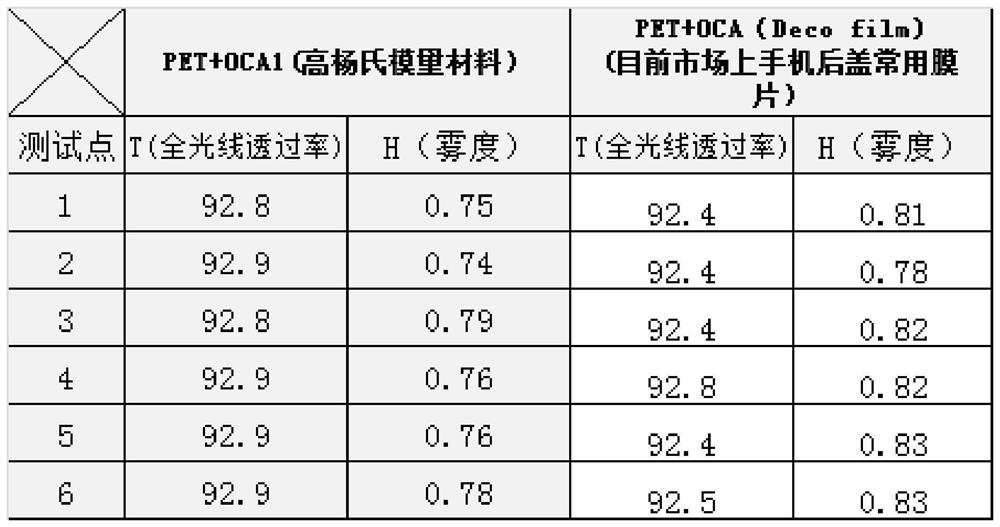

[0032] Figure 1-3 It shows a method and structure for increasing the strength of glass disclosed in the present invention, wherein a method for increasing the strength of glass includes glass, and also includes the following processing methods:

[0033] S1, clean the glass first, and then perform plasma treatment on the glass, wherein the WCA of the glass surface is less than 10°;

[0034] S2, spraying high Young's modulus material on the glass;

[0035] S3, pre-baking the glass sprayed in S3, the pre-baking temperature is 90-120°C;

[0036] S4, and then bake the pre-baked glass in S4 at a temperature of 160-200° C. for 50-70 minutes.

[0037] S5, attaching a film on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com