An online monitoring device and method for laser cleaning based on temperature perception

A technology of laser cleaning and monitoring device, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem of inability to accurately judge whether the surface of the object to be cleaned is clean, the high cost of laser-induced breakdown spectroscopy, and the technical skills of operators. High level requirements, to achieve the effect of simple structure, low cost, and low technical level requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

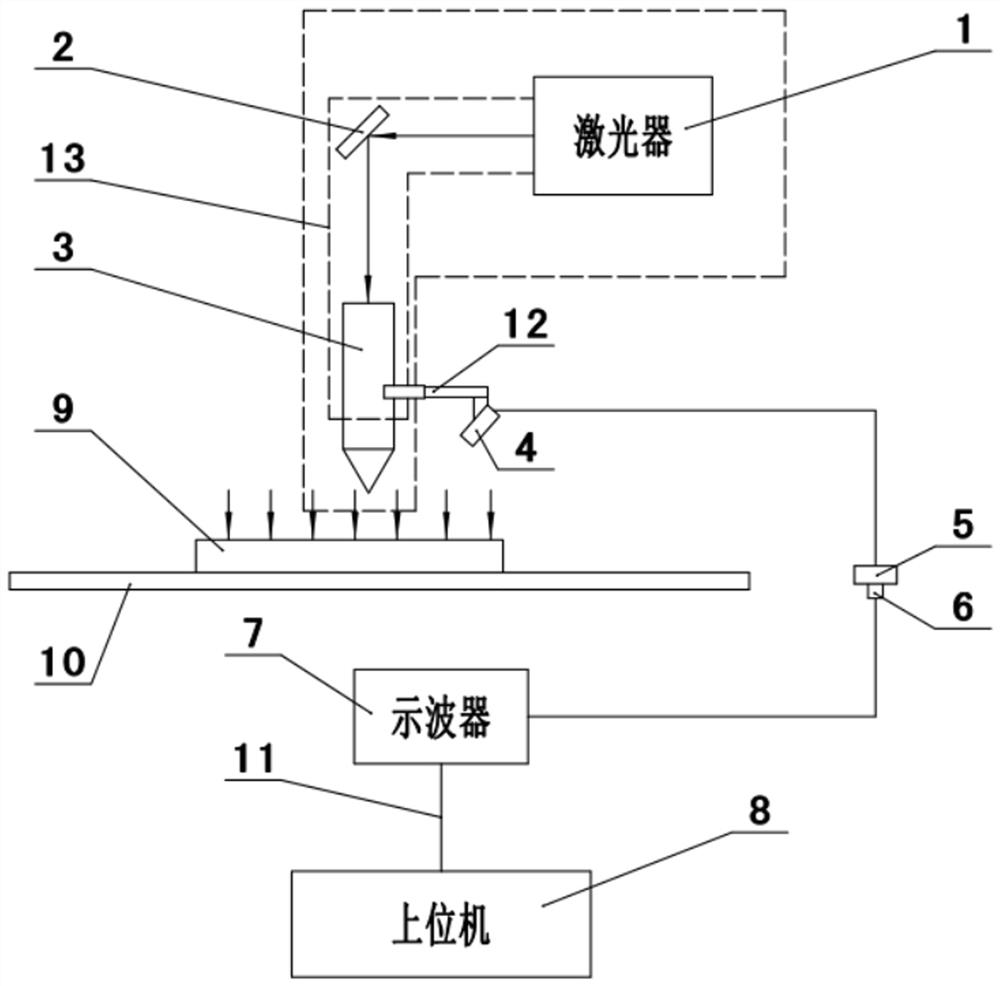

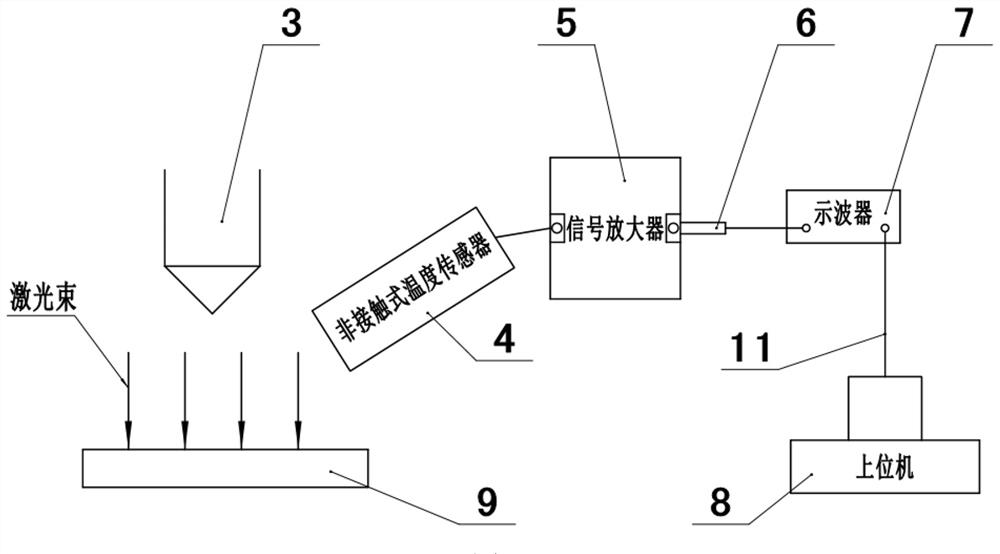

[0035] In order to make the device structure, technical principle and implementation method of the present invention more intuitive and clear, the following examples and accompanying drawings will be used for description.

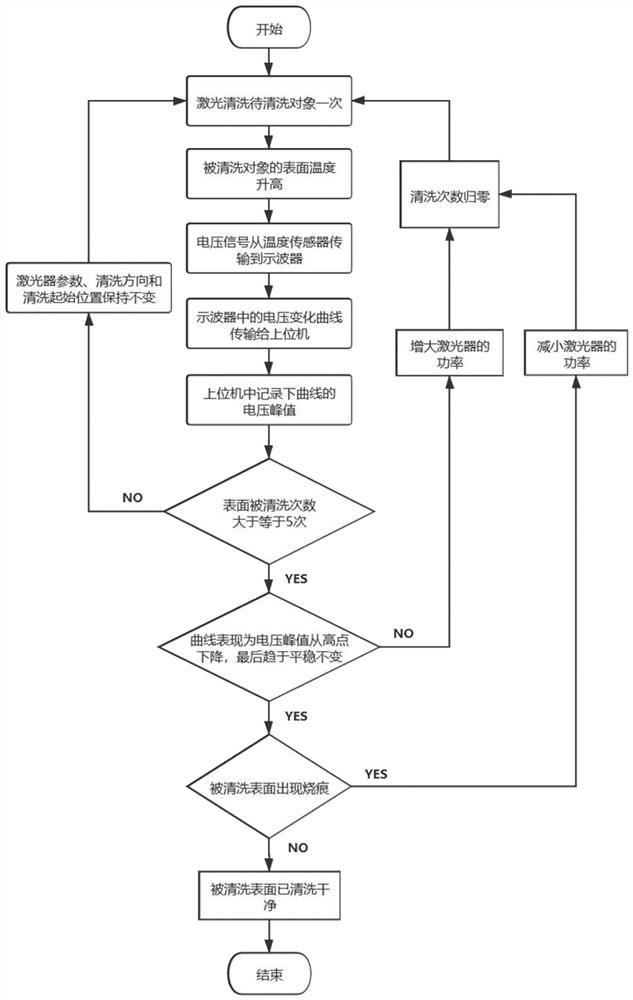

[0036] The monitoring principle involved in the present invention is that under the irradiation of laser light, both the pollutant and the substrate will absorb heat and heat up; but due to the different thermophysical parameters of different substances, when they are cleaned, the temperature rise rate and temperature peak value of the two are Different, the measured voltage peak is also different. Under the condition of keeping the same laser parameters, cleaning direction and cleaning starting position for each cleaning, according to this monitoring principle, after cleaning the surface to be cleaned for many times, if the drawn voltage peak change curve appears with the cleaning times With the increase of , the voltage peak change curve starts to decreas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com