Coupling and boring axle hole accuracy guarantee method

A technology of shaft coupling and shaft hole, which is applied in boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc. It can solve problems such as poor boring accuracy, large machining deviation, and large equipment stroke. Achieve the effect of small precision deviation, small vibration and high position precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

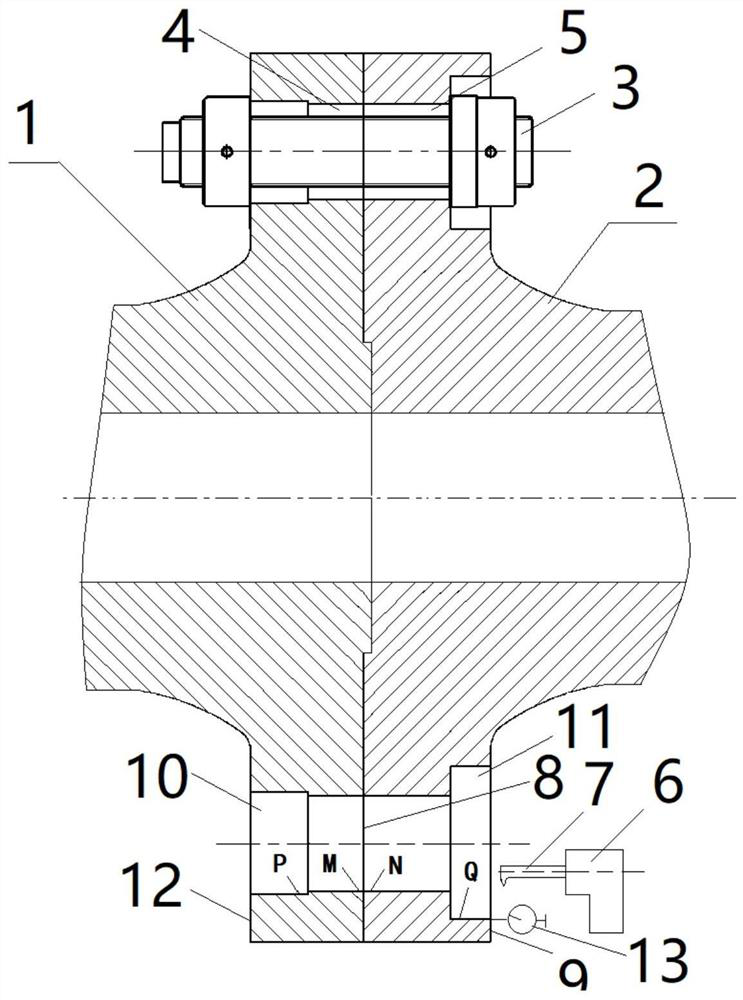

[0027] 1) The single-piece turbine shaft 1 and generator shaft 2 are qualified for finish turning, the parallelism between the flange surface 12 of turbine shaft 1 and the legal flange surface 8 of the two shaft handles after finish turning is not greater than 0.03mm, and the flange surface 9 of generator shaft 2 The parallelism with the two-axis handlebar flange surface 8 after finish turning is not more than 0.03mm;

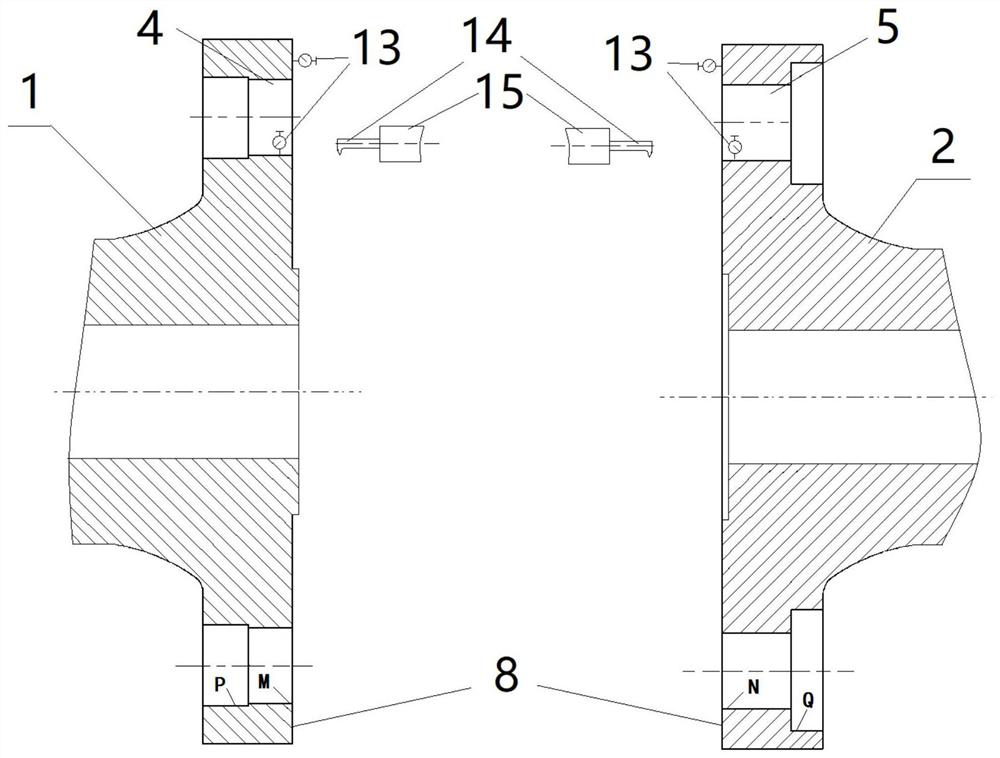

[0028] 2) The two shafts are assembled together with joint bolts 3, the gap between the joint flanges 8 is less than 0.02mm, the joint bolts 3 are evenly distributed every other hole according to the shaft hole distribution pitch circle, and the torque is evenly jointed, see figure 1 ;

[0029] 3) After the two-axis coupling is assembled, check the coaxiality of the coupling shaft system on the lying car, and after confirming that the coaxiality meets the IEEE810 standard, hoist the lying car and lay it on the boring machine platform;

[0030] 4) Set up the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com