Long-steel-rail hoisting numerical control synchronous centralized control system with electrical anti-swing function

A centralized control system and long rail technology, applied in safety devices, transportation and packaging, load suspension components, etc., can solve problems such as low efficiency requirements, inability to install mechanical anti-swing devices, and affect the use effect, etc., to achieve Safe operation, easy implementation, and simple control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

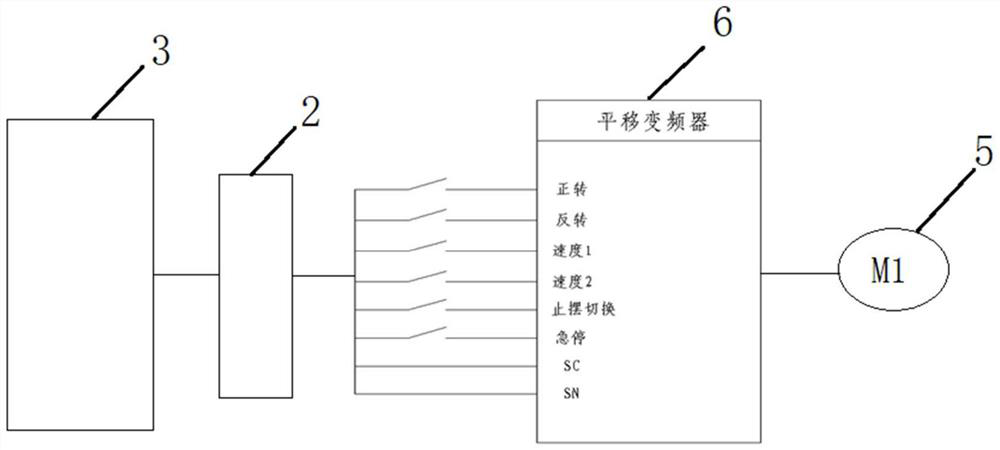

[0026] figure 1 It is a schematic diagram of the open-loop anti-swing control mode of the present invention, wherein the translation frequency converter 6 is connected with the translation motor 5, and the rotational speed of the translation motor 5 is controlled by the output frequency of the translation frequency converter 6, thereby controlling the transport speed of the hanging object 10, and the translation frequency conversion The inverter 6 is connected to the PLC 3 through the relay 2, and the start and stop of the translation frequency converters 6 on all cranes 1 are centrally controlled by the PLC 3 through the relay 2.

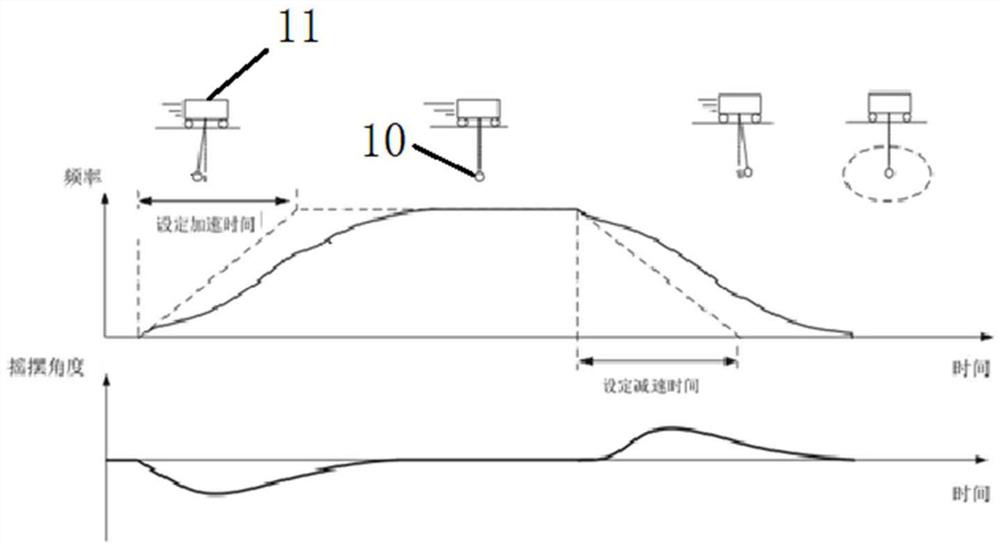

[0027] image 3 It is a schematic diagram of the anti-swing control of the translational frequency converter of the present invention. The PLC 3 outputs a trigger control signal. By setting the acceleration time, within the set acceleration time, the frequency of the translational frequency converter 6 is increased from zero to the set frequency, a...

no. 2 example

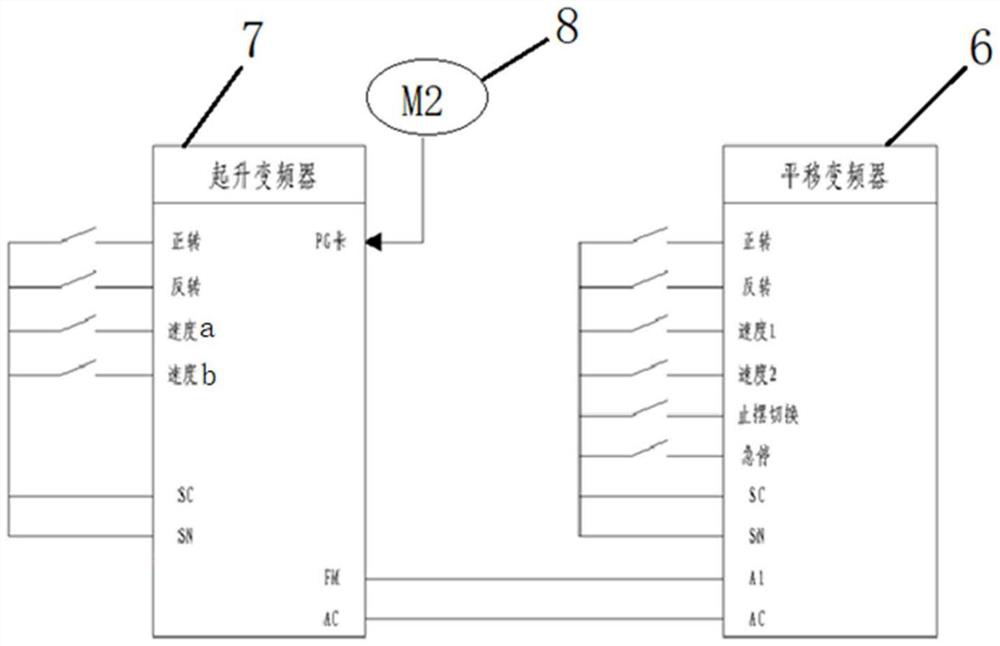

[0030] Such as figure 2 It is a schematic diagram of the closed-loop anti-sway control mode of the present invention, which adds a lifting frequency converter 7 and a lifting motor 8, and the lifting motor 8 is connected with the lifting frequency converter 7, and the rotating speed of the lifting motor 8 is determined by the output frequency Control, and then control the lifting speed of the hanging object 10. The second embodiment is similar to the first embodiment, the difference is that it is not necessary to set the lifting height of the hanging object 10 in advance, and the lifting frequency converter 7 is added, which can collect in real time when the crane 1 performs the lifting operation, The actual lifting height H1 of the hanging object 10 is then fed back to the translation frequency converter 6 of the crane 1, and then the setting of the acceleration and deceleration time in the translation frequency inverter 6 is adjusted by the PLC 3 to prevent the lifting of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com