Underwater self-compacting concrete and preparation method thereof

A self-compacting concrete and cement technology, applied in the field of concrete, can solve the problems of incompatibility with underwater engineering, loss of aggregate bonding ability, loss of cement slurry, etc., to improve self-compacting, reduce the possibility of collapse, reduce Small mixing and self-compacting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

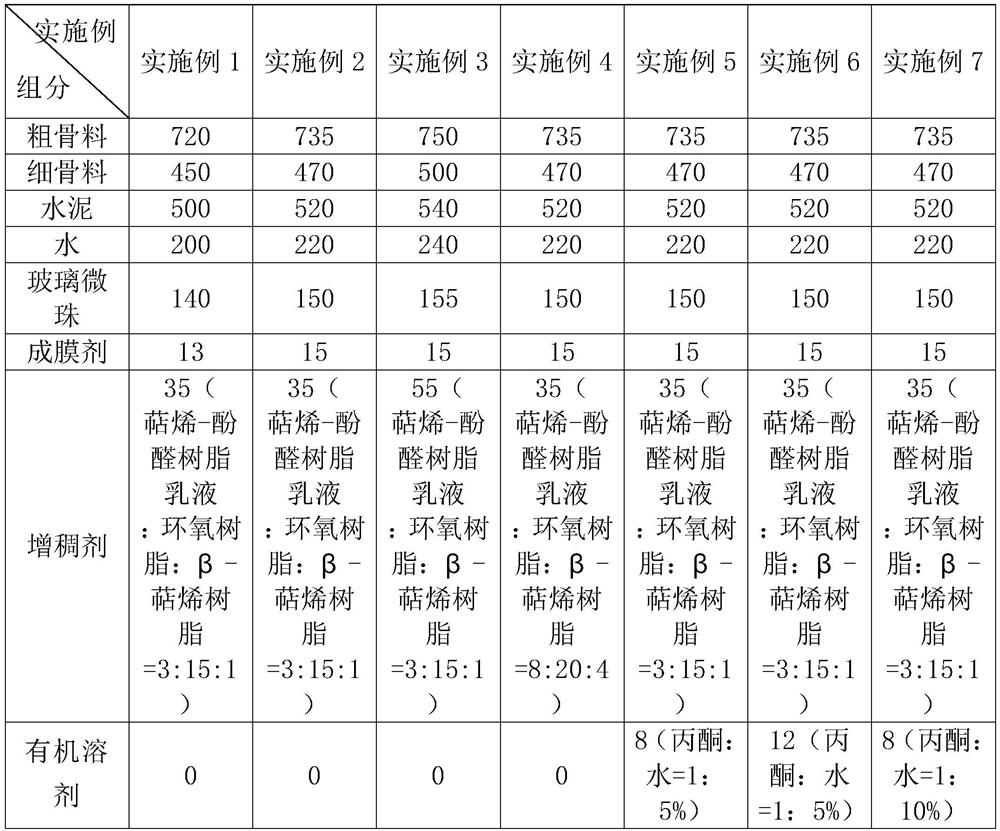

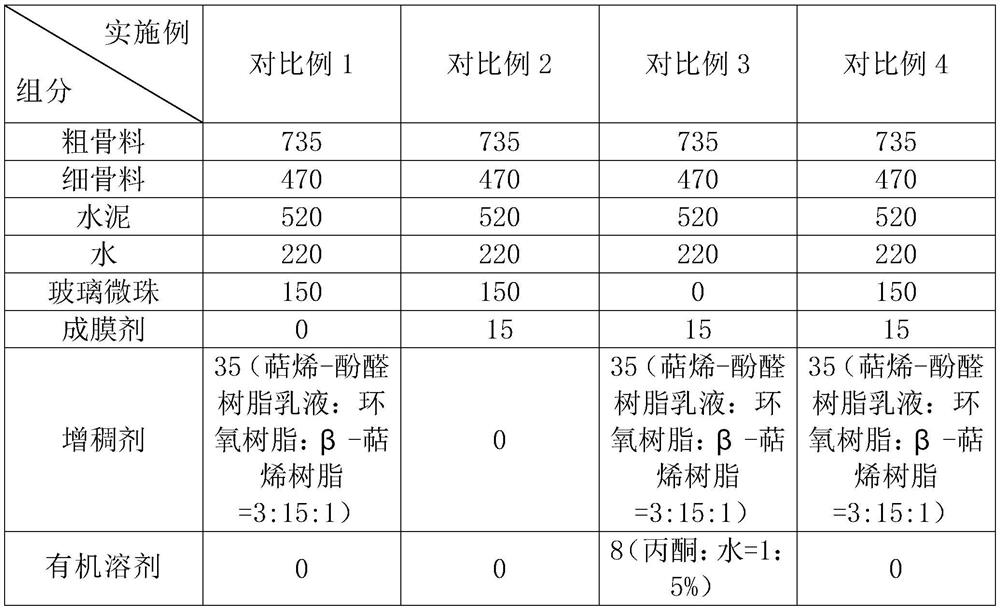

Embodiment 1- Embodiment 4

[0044] The preparation method of embodiment 1-embodiment 4 is as follows:

[0045] s1: According to the ratio in Table 2, mix the terpene-phenolic resin emulsion, epoxy resin and β-terpene resin, and use a stirrer to mix evenly to obtain a thickener for use;

[0046] s2: According to the ratio in Table 2, the coarse aggregate and the fine aggregate are uniformly mixed by a stirrer to obtain an aggregate mixture;

[0047] s3: according to the ratio in Table 2, mix the cement and the porous microbeads with a mixer, add water and mix well to obtain a gel mixture;

[0048] s4: According to the ratio in Table 2, add the gel mixture, thickener and film-forming agent to the aggregate mixture sequentially under stirring with a stirrer, and stir evenly to obtain underwater self-compacting concrete.

[0049] The difference between the preparation method of embodiment 5-7 and embodiment 1 is:

[0050] In step s3, firstly soak the glass microspheres in the hardener completely according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com