Method for recycling springback material of RH dip pipe gunning material

A recycling method and gunning material technology, which is applied in the field of refractory material recycling, can solve the problems of gunning material waste, less research, and affecting the working environment, and achieve the effects of simplifying production ratios, improving high-temperature strength, and reducing steel consumption per ton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

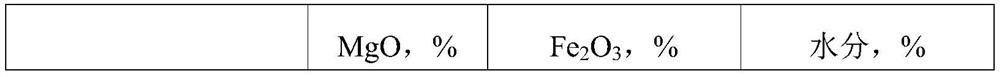

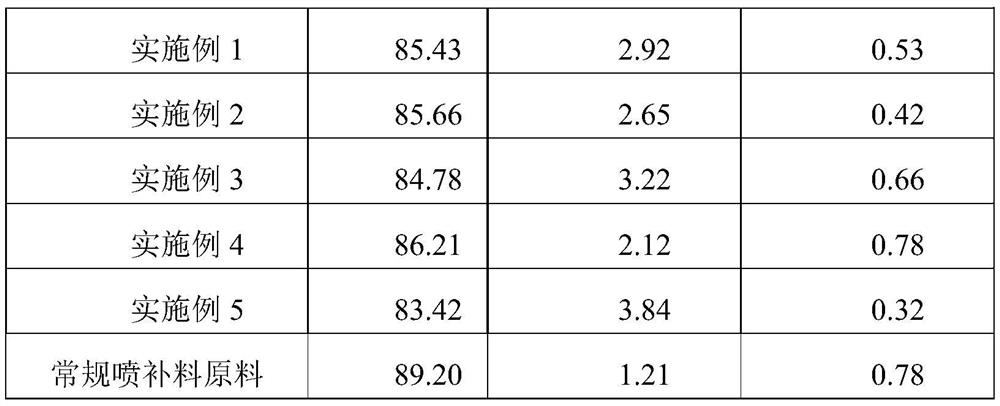

Examples

Embodiment 1

[0059] This embodiment discloses a method for recycling rebound material of RH dip tube gunning material, which includes the following steps:

[0060] 1) Collect the rebound material of the RH dip tube gunning material scattered around the gunning vehicle and the RH vacuum furnace into a collecting hopper near the RH vacuum furnace, and place it for 24 hours; use the radiant heat of the RH vacuum furnace to remove the gunning material back Most of the moisture in the ammunition.

[0061] 2) the rebound material collected in step 1) is further selected to be collected with a half-ton bag, and then primary screening is carried out. The sieve particle size selected by the primary screening is 10mm, and the primary screening undersize is collected;

[0062] 3) Heat-treat the primary screening undersize collected in step 2) at 200° C.; usually for 4 hours to further remove the moisture in the primary screening undersize.

[0063] 4) The heat-treated material in step 3) is crushed ...

Embodiment 2

[0073] This embodiment discloses a method for recycling rebound material of RH dip tube gunning material, which includes the following steps:

[0074] 1) Collect the rebound material of the RH dip tube gunning material scattered around the gunning vehicle and the RH vacuum furnace into a collecting hopper near the RH vacuum furnace, and place it for 36 hours; use the radiant heat of the RH vacuum furnace to remove the gunning material back Most of the moisture in the ammunition.

[0075] 2) the rebound material collected in step 1) is further selected to be collected with a half-ton bag, and then primary screening is carried out. The sieve particle size selected by the primary screening is 15mm, and the primary screening undersize is collected;

[0076] 3) Heat-treat the primary screening undersize collected in step 2) at 150° C.; usually for 5 hours to further remove the moisture in the primary screening undersize.

[0077] 4) The heat-treated material in step 3) is crushed ...

Embodiment 3

[0087] This embodiment discloses a method for recycling rebound material of RH dip tube gunning material, which includes the following steps:

[0088] 1) Collect the rebound material of the RH dipping tube gunning material scattered around the gunning vehicle and the RH vacuum furnace into a collecting hopper near the RH vacuum furnace, and place it for 48 hours; use the radiant heat of the RH vacuum furnace to remove the gunning material back Most of the moisture in the ammunition.

[0089] 2) the rebound material collected in step 1) is further selected to be collected with a half-ton bag, and then primary screening is carried out, and the sieve particle size selected by the primary screening is 20mm, and the primary screening undersize is collected;

[0090] 3) The primary screening undersize collected in step 2) is subjected to heat treatment at 200°C; usually for 6 hours to further remove the moisture in the primary screening undersize.

[0091] 4) The heat-treated mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com