Ceramic material capable of absorbing water and permeating water, and preparation method thereof

A technology for ceramic materials and waste ceramics, which is applied to ceramic products, other household appliances, trays, etc., can solve the problems of stagnant water that is easy to deteriorate and stink, affects beautiful use, complex structure, etc., and achieves good ability to adsorb glaze layer, good The effect of structural stability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preferred embodiment of the present invention provides a ceramic material that can absorb water and seep water, and make it into the shape of a tea tray. The specific process is: grind and grind the waste ceramic slag, and pass it through a 20-mesh screen. After the pyrolusite slurry is completely reacted with sulfur dioxide, the pyrolusite desulfurization waste residue is obtained. The Henan Xinyang bentonite and Jiangxi Jingdezhen porcelain clay are uniformly kneaded and integrated with the above-mentioned waste ceramic slag and pyrolusite desulfurization waste residue. Among them, the waste ceramic slag : Pyrolulurite desulfurization waste residue: bentonite: china clay with a mass ratio of 2:1:1:1, beat and shape the mixed mud.

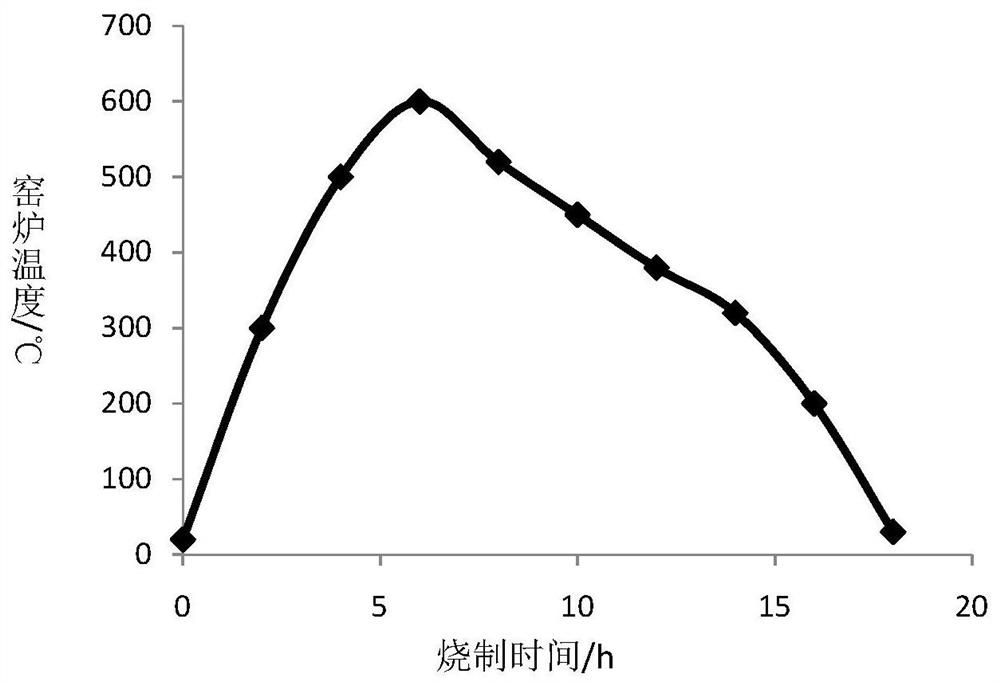

[0048] The shaped mixed mud is dried at room temperature, then bisque-fired at 600°C, and the temperature curve of the bisque-fired process is shown in figure 1 As shown, the temperature in the kiln rises gradually, and after about 7 ho...

Embodiment 2

[0051] The preferred embodiment of the present invention provides a ceramic material that can absorb water and seep water, and make it into the shape of a tea tray. The specific process is: grind and grind the waste ceramic slag, and pass it through a screen with a mesh number of 18. After the pyrolusite slurry is completely reacted with sulfur dioxide, the pyrolusite desulfurization waste residue is obtained. The Henan Xinyang bentonite and Jiangxi Jingdezhen porcelain clay are uniformly kneaded and integrated with the above-mentioned waste ceramic slag and pyrolusite desulfurization waste residue. Among them, the waste ceramic slag : Pyrolulurite desulfurization waste residue: bentonite: china clay with a mass ratio of 3:2:1:1, beat and shape the mixed mud.

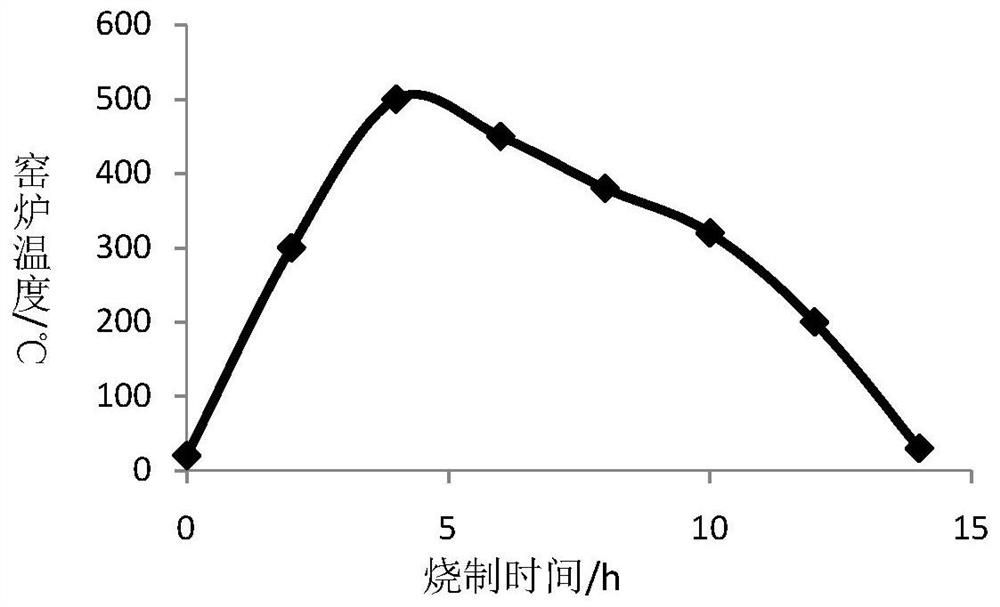

[0052] The shaped mixed mud is dried at room temperature, then bisque-fired at 500°C, and the temperature curve of the bisque-fired process is shown in image 3 As shown, the temperature in the kiln rises gradually. Aft...

Embodiment 3

[0055] The preferred embodiment of the present invention provides a ceramic material that can absorb water and seep water, and make it into the shape of a tea tray. The specific process is: grind and grind the waste ceramic slag, and pass it through a 16-mesh screen. After the pyrolusite slurry is completely reacted with sulfur dioxide, the pyrolusite desulfurization waste residue is obtained. The Henan Xinyang bentonite and Jiangxi Jingdezhen porcelain clay are uniformly kneaded and integrated with the above-mentioned waste ceramic slag and pyrolusite desulfurization waste residue. Among them, the waste ceramic slag : Desulfurization waste residue of pyrolusite: bentonite: China clay with a mass ratio of 5:2:1:1, beat and shape the mixed mud.

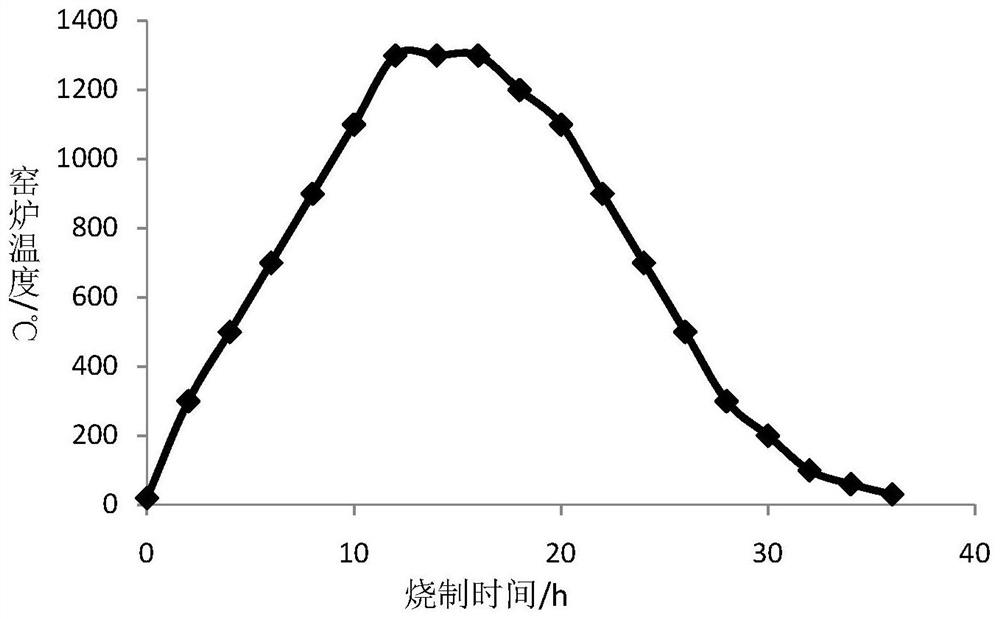

[0056] The shaped mixed mud is dried at room temperature, then bisque-fired at 650°C, and the temperature curve of the bisque-fired process is shown in Figure 5 As shown, the temperature in the kiln rises gradually, and after about 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com