Preparation method of ethyl 4-chloroacetoacetate

A technology of ethyl chloroacetoacetate and ethyl acetoacetate is applied in the field of preparation of ethyl 4-chloroacetoacetate, and can solve the problems such as low efficiency of ethyl 4-chloroacetoacetate, inability to meet the requirements of the preparation method, and the like, Accurate and stable temperature control, easy to implement, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

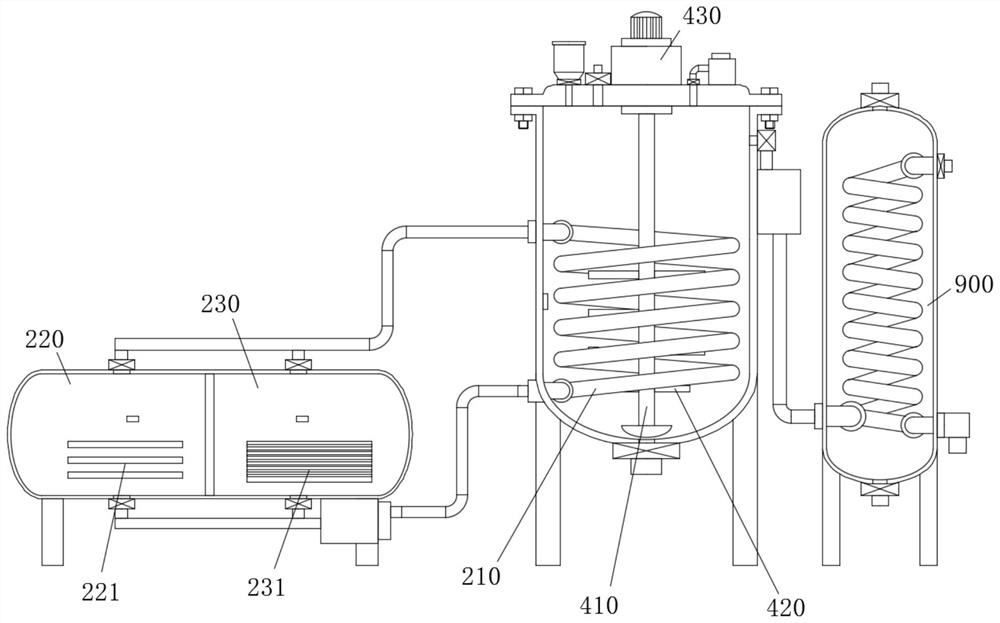

Image

Examples

Embodiment 1

[0026] A preparation method for ethyl 4-chloroacetoacetate, comprising the steps of:

[0027] Step 1: First, add ethyl acetoacetate in the reactor, and cool it to 05°C;

[0028] Step 2: Then add sulfuryl chloride dropwise to the reactor, keeping the temperature of the reaction solution at 0°C;

[0029] Step 3: After the dropwise addition, stir and react at room temperature for 2 hours;

[0030] Step 4: Then remove the gas in the reactor under the condition of 35°C;

[0031] Step 5: Then, the unreacted ethyl acetoacetate is recovered by distillation when the temperature is raised to 85°C;

[0032] Step 6: Finally, cool to 30°C to obtain crude ethyl 4-chloroacetoacetate.

[0033] The molar ratio of ethyl acetoacetate and sulfuryl chloride is 4.5:4.

Embodiment 2

[0035] A preparation method for ethyl 4-chloroacetoacetate, comprising the steps of:

[0036] Step 1: First, add ethyl acetoacetate in the reactor, and cool it down to 2.5°C;

[0037] Step 2: Then add sulfuryl chloride dropwise to the reactor, keeping the temperature of the reaction solution at 2.5°C;

[0038] Step 3: after the dropwise addition, stir and react at room temperature for 3 hours;

[0039] Step 4: then remove the gas in the reactor under the condition of 45°C;

[0040] Step 5: Then, the unreacted ethyl acetoacetate is recovered by distillation when the temperature is raised to 90°C;

[0041] Step 6: Finally, cool to 30°C to obtain crude ethyl 4-chloroacetoacetate.

[0042] The molar ratio of ethyl acetoacetate and sulfuryl chloride is 5.05:4.5.

Embodiment 3

[0044] A preparation method for ethyl 4-chloroacetoacetate, comprising the steps of:

[0045] Step 1: First, add ethyl acetoacetate in the reactor, and cool it to 5°C;

[0046] Step 2: Then add sulfuryl chloride dropwise to the reactor, keeping the temperature of the reaction solution at 5°C;

[0047] Step 3: after the dropwise addition, stir and react at room temperature for 4 hours;

[0048] Step 4: Then, the gas in the reactor is pumped out under the condition of 55° C.;

[0049] Step 5: Then, the unreacted ethyl acetoacetate is recovered by distillation when the temperature is raised to 95°C;

[0050] Step 6: Finally, cool to 30°C to obtain crude ethyl 4-chloroacetoacetate.

[0051] The molar ratio of ethyl acetoacetate and sulfuryl chloride is 5.6:5.

[0052] The reactor in the preparation method of ethyl 4-chloroacetoacetate proposed by the present invention can realize the rapid production of crude ethyl 4-chloroacetoacetate by using ethyl acetoacetate and sulfuryl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com