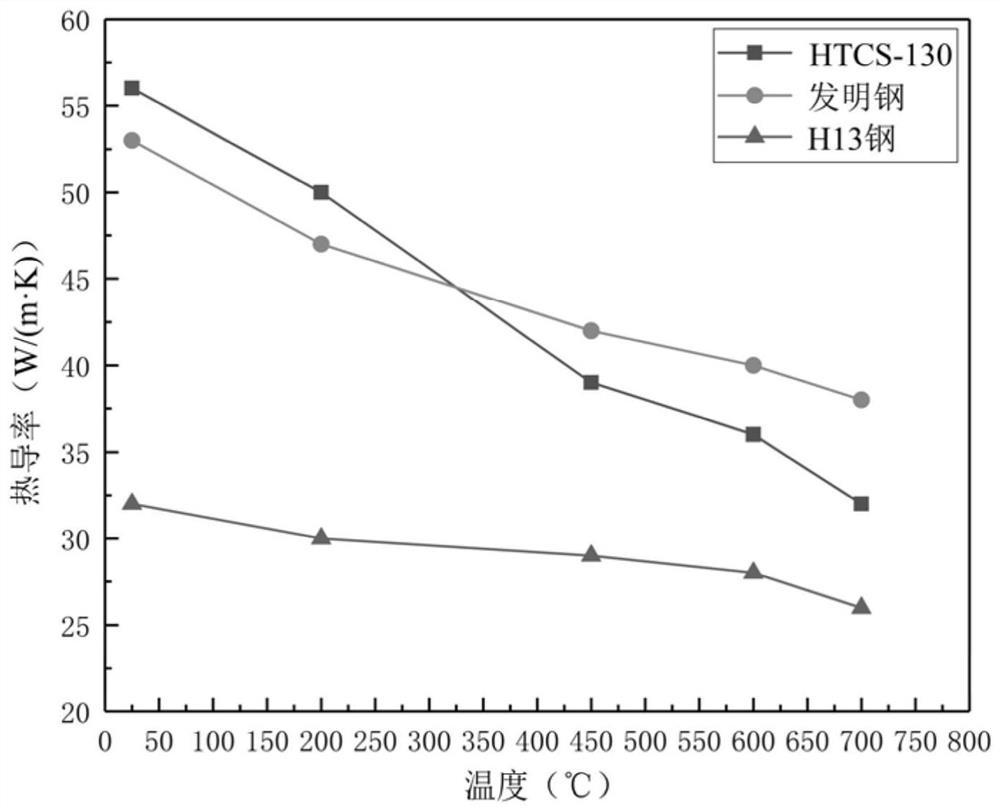

Die steel with low cost and high thermal conductivity at high temperature, and preparation method of die steel

A high thermal conductivity, die steel technology, applied in the field of die steel and its preparation, can solve problems such as insufficient thermal conductivity, and achieve the effects of improved thermal conductivity, low cost, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Group A

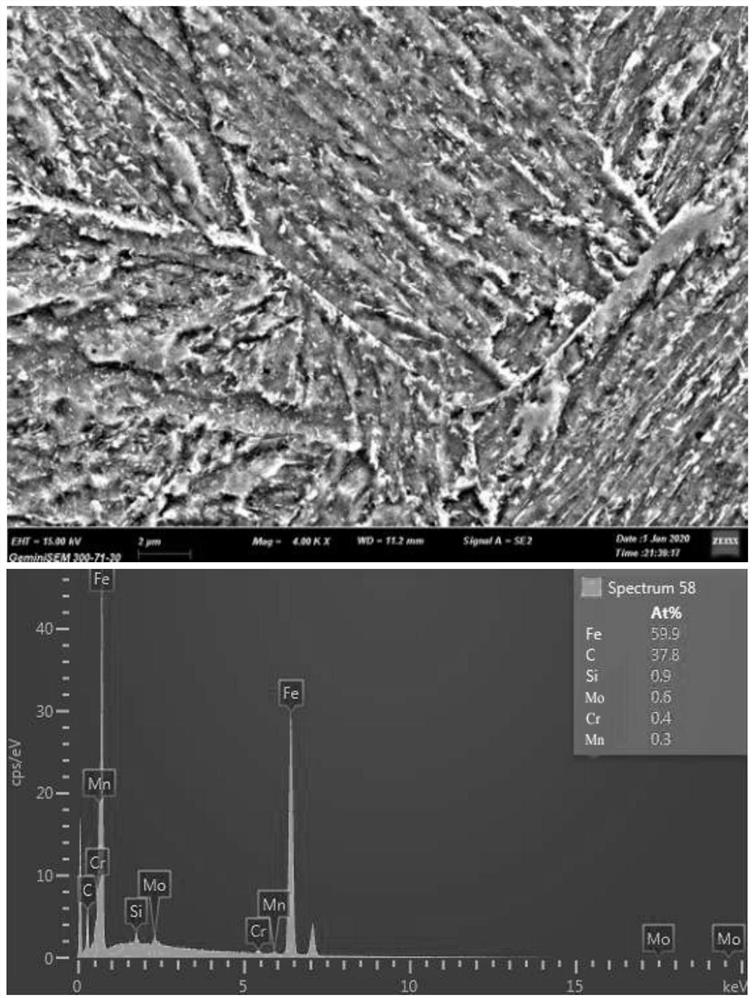

[0029] In this embodiment, the high thermal conductivity die steel, by weight percentage (wt.%), its matrix has the following element composition: C0.31%, Cr0.43%, Si0.73%, Mn0.47%, Mo1.15 %, V0.079%, the rest is iron and trace unavoidable impurities.

[0030] The preparation method of high thermal conductivity die steel in the present embodiment is as follows:

[0031] 1. Melting: After the alloy is designed according to the above-mentioned composition ratio, it is melted and prepared in a vacuum induction melting furnace, heated to 1600°C, kept for 30 minutes, and cooled to room temperature to obtain an ingot.

[0032] 2. Heat treatment process parameters: Quenching temperature is 1020°C, quenching method is oil quenching; primary tempering temperature is 620°C, holding time is 1h; secondary tempering temperature is 590°C, holding time is 1h. Under the set heat treatment process conditions, the hardness can reach 47HRC.

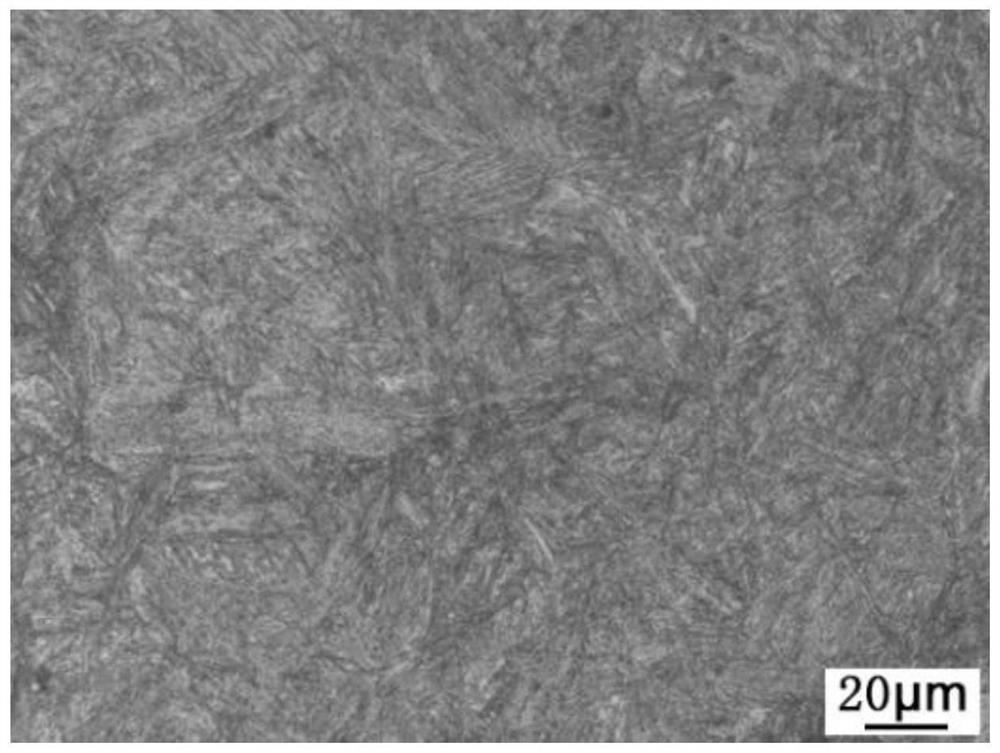

[0033] Such as fig...

Embodiment 2

[0034] Embodiment 2: Group B

[0035] In this embodiment, the high thermal conductivity die steel, by weight percentage (wt.%), its matrix has the following element composition: C0.33%, Cr0.40%, Si0.70%, Mn0.45%, Mo1.05 %, V0.08%, the rest is iron and trace unavoidable impurities.

[0036] The preparation method of the high thermal conductivity die steel of the present embodiment is as follows:

[0037] 1. Melting: After the alloy is designed according to the above-mentioned composition ratio, it is melted and prepared in a vacuum induction melting furnace, heated to 1600°C, kept for 30 minutes, and cooled to room temperature to obtain an ingot.

[0038] 2. Heat treatment process parameters: Quenching temperature is 1000°C, quenching method is oil quenching; primary tempering temperature is 600°C, holding time is 1h; secondary tempering temperature is 580°C, holding time is 1h. Under the set heat treatment process conditions, the hardness can reach 48HRC.

[0039] Such as ...

Embodiment 3

[0040] Embodiment 3: Group C

[0041] In this embodiment, the high thermal conductivity die steel, by weight percentage (wt.%), its matrix has the following element composition: C0.32%, Cr0.45%, Si0.68%, Mn0.47%, Mo1.11%, V0.08%, the rest is iron and trace unavoidable impurities.

[0042] The preparation method of the high thermal conductivity mold steel of the present embodiment:

[0043] 1. Melting: After the alloy is designed according to the above-mentioned composition ratio, it is melted and prepared in a vacuum induction melting furnace, heated to 1600°C, kept for half an hour, cooled to room temperature to obtain an ingot.

[0044] 2. Heat treatment process parameters: Quenching temperature is 1020°C, quenching method is oil quenching; primary tempering temperature is 600°C, holding time 1h; secondary tempering temperature is 580°C, holding time 1h. Under the set heat treatment process conditions, the hardness can reach 47HRC.

[0045] Such as Figure 5 Shown is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com