Metallographic corroding agent and preparation method and application thereof

A kind of etchant, liquid phase technology, applied in the field of metallographic etchant and preparation, to achieve the effect of easy to use, simple preparation, wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the above-mentioned metallographic etchant is as follows: first, measure 40-55% hydrochloric acid, 37-48% ultrapure water and 8-12% glycerol according to the volume percentage, and add The ratio of 7-16g of copper sulfate and 2-6g of ferric chloride was weighed to measure the corresponding proportions of copper sulfate and ferric chloride; then slowly add concentrated hydrochloric acid and glycerin into ultrapure water and keep stirring , until the liquid phase is mixed evenly; finally, the copper sulfate and ferric chloride weighed in proportion are gradually added to the above liquid phase until they are completely dissolved to obtain a metallographic etchant.

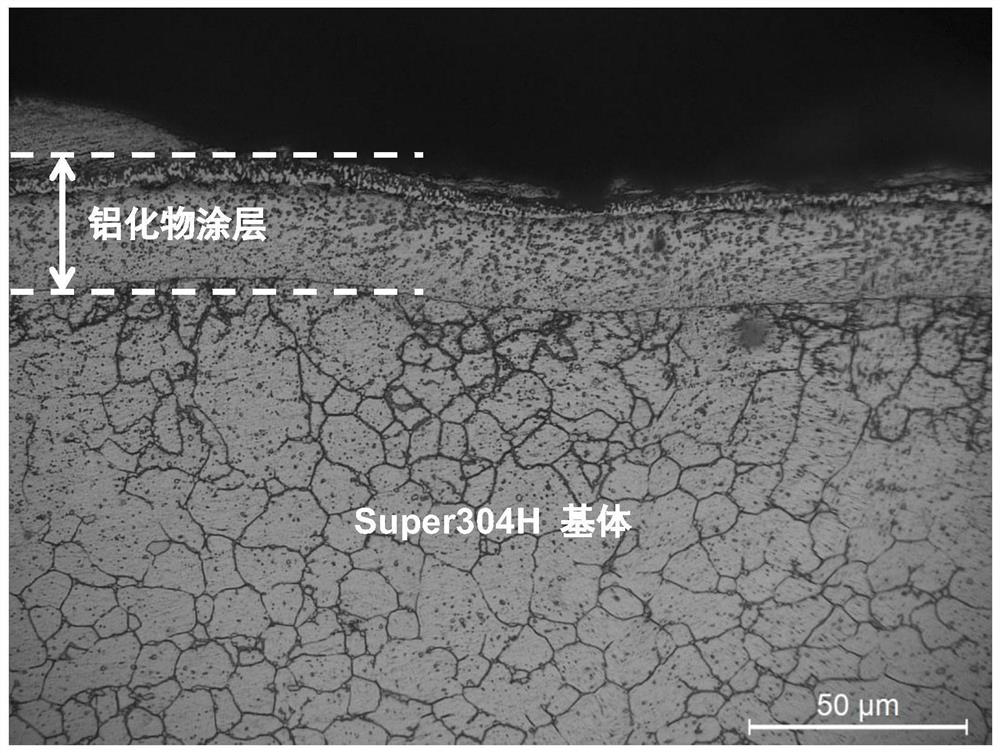

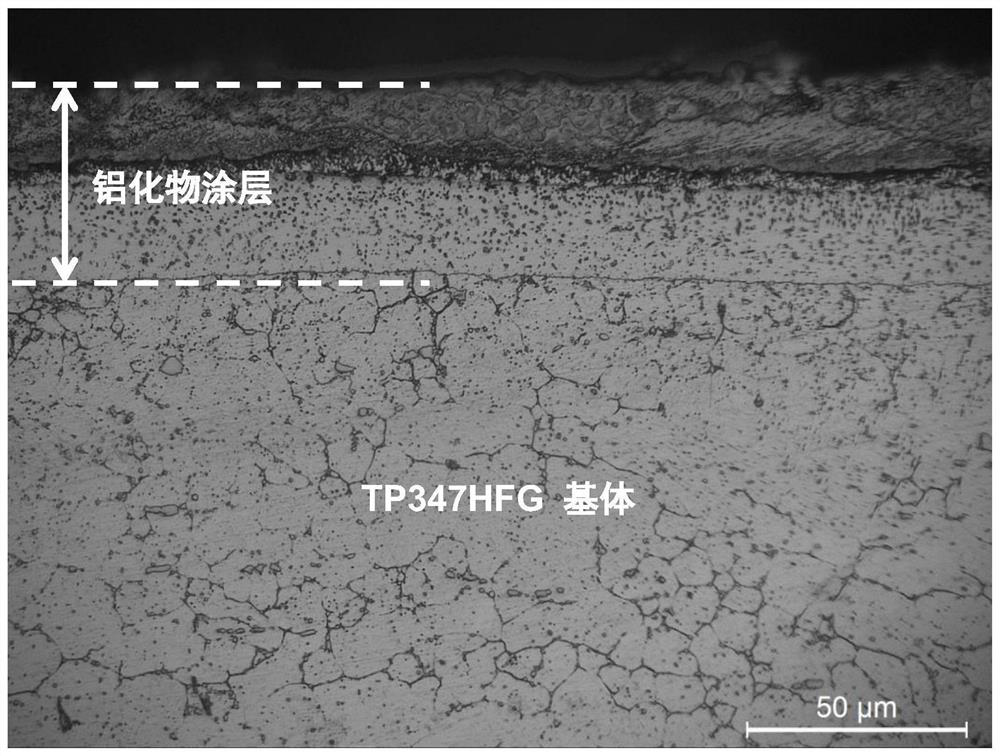

[0033]The further improvement of the present invention is: aiming at the aluminide coating on the surface of the austenitic steel in the original state (serving for 0 hours), it is composed of the following volume and mass components: 55mL of concentrated hydrochloric acid, 37mL of ult...

Embodiment 6

[0052] Step 1: Preparation of corrosion samples

[0053] The original austenitic steel aluminide coating sample was hot-mounted along the coating cross-section direction and marked on the sample with an electric engraving pen; #, 1200#, 2000# Water-grinding metallographic sandpaper is ground step by step; finally, the sample is polished on a polishing machine with a polishing cloth or flannelette until the surface reaches a mirror-level brightness, and there are no coarse scratches visible to the naked eye. The powder is conductive mounting powder, the polishing paste is 1.5 μm diamond spray polishing agent, and the grinding and polishing directions are perpendicular to the coating direction.

[0054] Step 2: Preparation of metallographic etchant

[0055] According to volume percentage, mix 44% concentrated hydrochloric acid, 46% ultrapure water and 10% glycerol uniformly to obtain a liquid phase, add copper sulfate and ferric chloride to the liquid phase, and mix uniformly t...

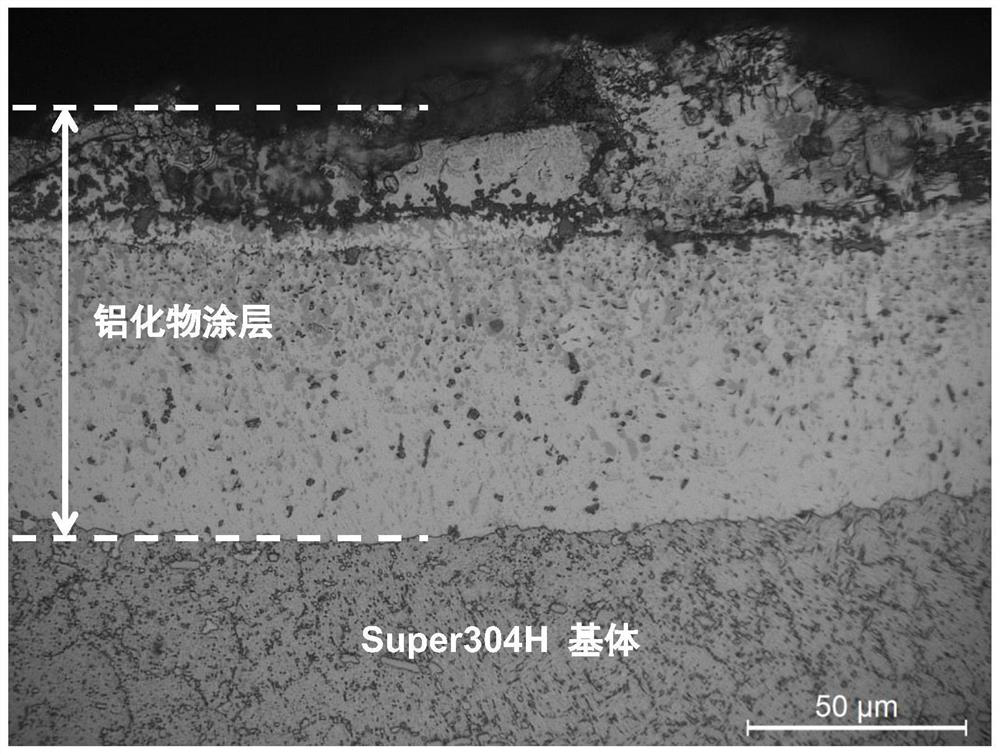

Embodiment 7

[0059] Step 1: Preparation of corrosion samples

[0060] The original austenitic steel aluminide coating sample was hot-mounted along the coating cross-section direction and marked on the sample with an electric engraving pen; #, 1200#, 2000# Water-grinding metallographic sandpaper is ground step by step; finally, the sample is polished on a polishing machine with a polishing cloth or flannelette until the surface reaches a mirror-level brightness, and there are no coarse scratches visible to the naked eye. The powder is conductive mounting powder, the polishing paste is 1.5 μm diamond spray polishing agent, and the grinding and polishing directions are perpendicular to the coating direction.

[0061] Step 2: Preparation of metallographic etchant

[0062] According to volume percentage, mix 52% concentrated hydrochloric acid, 37% ultrapure water and 11% glycerol uniformly to obtain a liquid phase, add copper sulfate and ferric chloride to the liquid phase, and mix uniformly t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com