Multi-start system with pneumatic pressurizing units for liquid-propellant rocket engine

A rocket engine and pneumatic supercharging technology, which is applied in rocket engine devices, jet propulsion devices, machines/engines, etc., can solve the problems of slow start-up acceleration of engines, large structural quality, and complex systems, so as to improve reliability and structure. The effect of light weight and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in conjunction with embodiment.

[0025] In order to achieve more than 20 times of starting capability, and to ensure that the engine has better starting acceleration and multiple starting consistency, the present invention proposes a multiple starting system of a pneumatic supercharging device. The starting system has a simple system and a Light weight, high working efficiency, good consistency in each starting condition, and small air consumption.

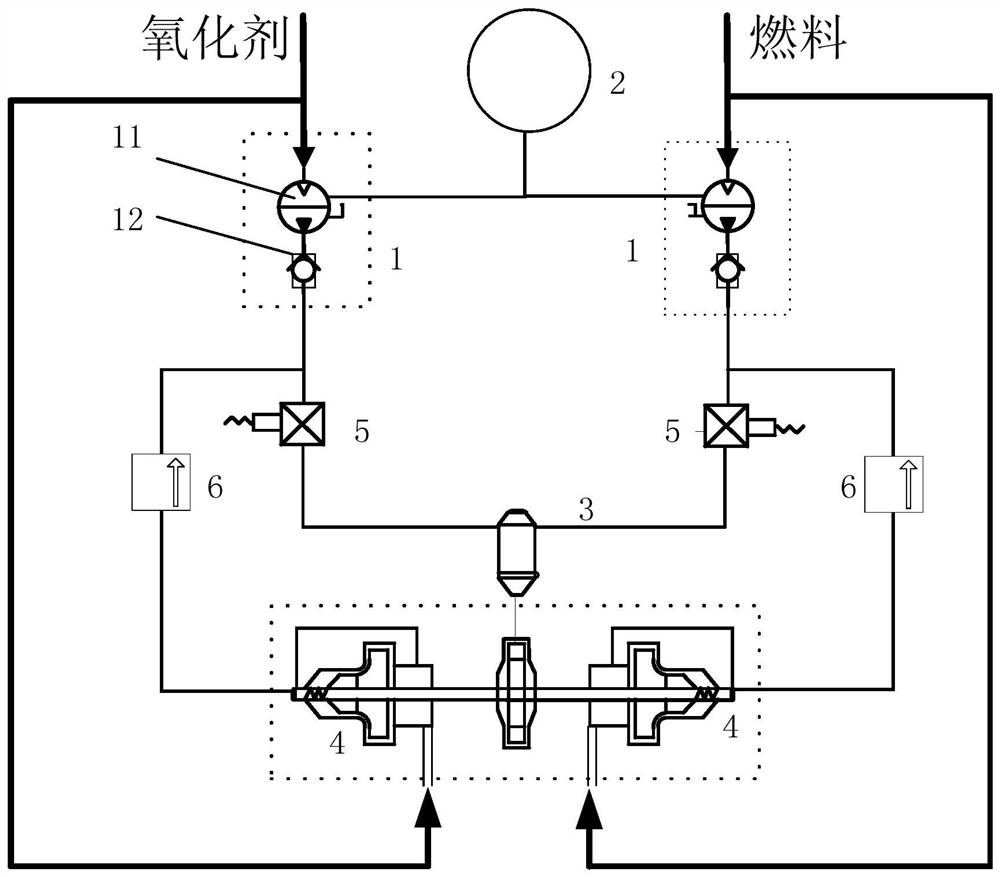

[0026] The technical solution of the present invention is: the pneumatic supercharging device 1 pressurizes the low-pressure propellant at the engine inlet under the action of the pressurized gas provided by the pressurized gas source 2, supplies the gas generator 3 for ignition, and the gas generator 3 produces The high-temperature gas drives the turbopump 4 to start. When the pressure behind the turbopump 4 is higher than the outlet pressure of the pneumatic booster ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com