Novel wear-resistant circular spin valve

A rotary valve, a new type of technology, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of scouring and wear of the gate and valve seat sealing surface, unsuitable service life, heavy opening and closing torque, etc., to achieve protection and sealing performance, improved service life, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

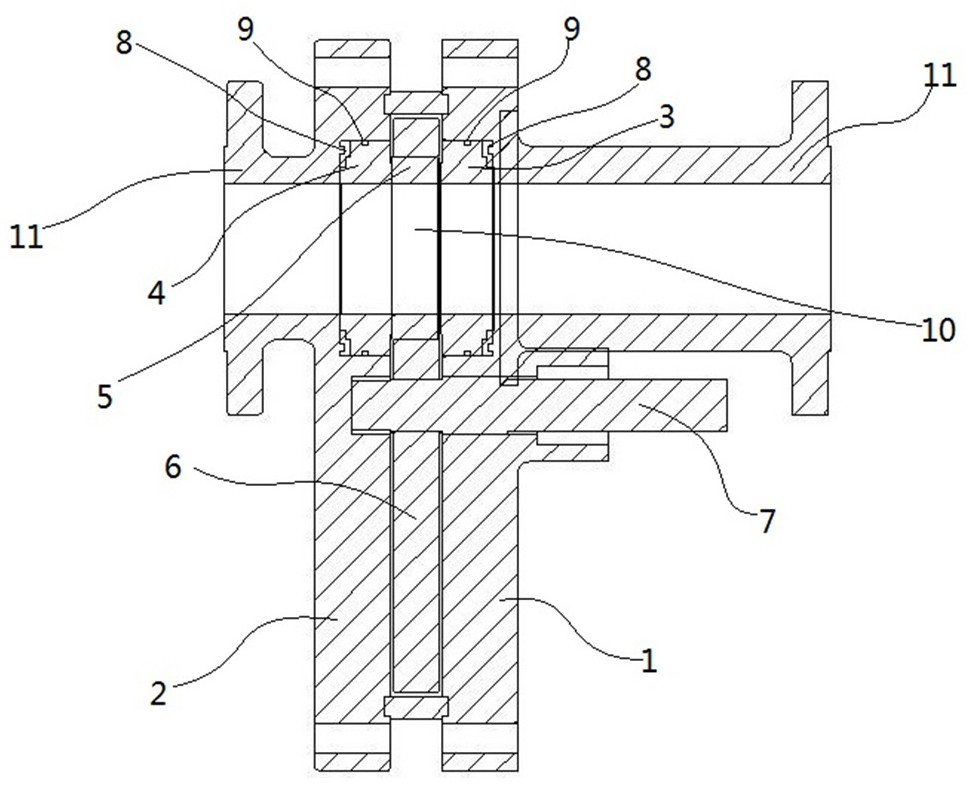

[0028] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further elaborated.

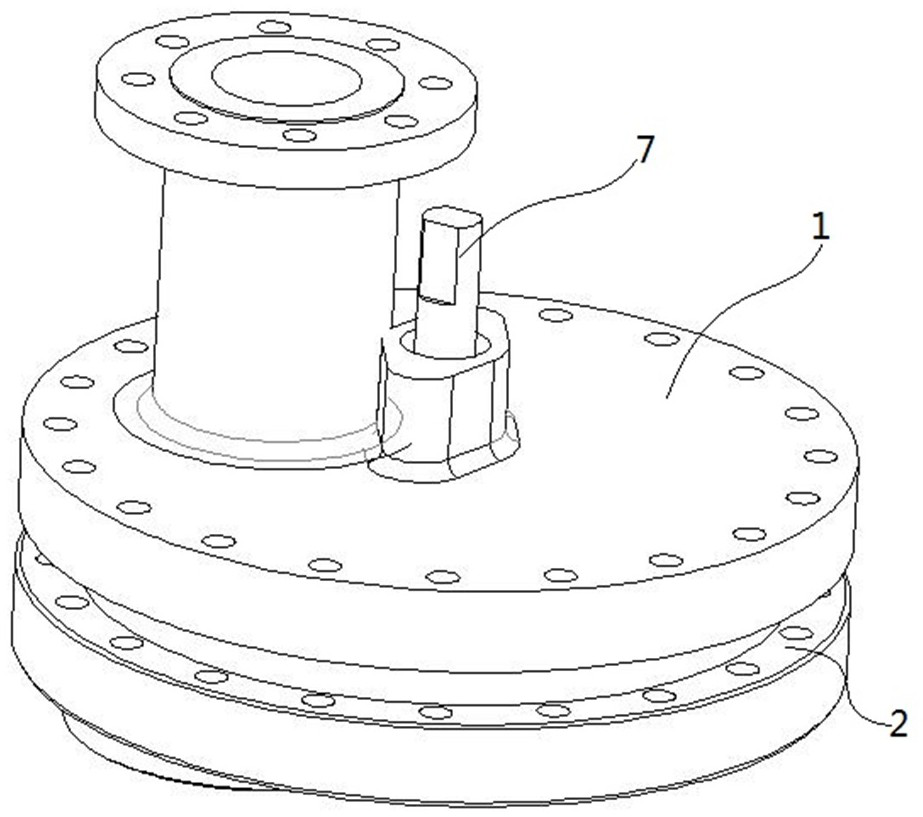

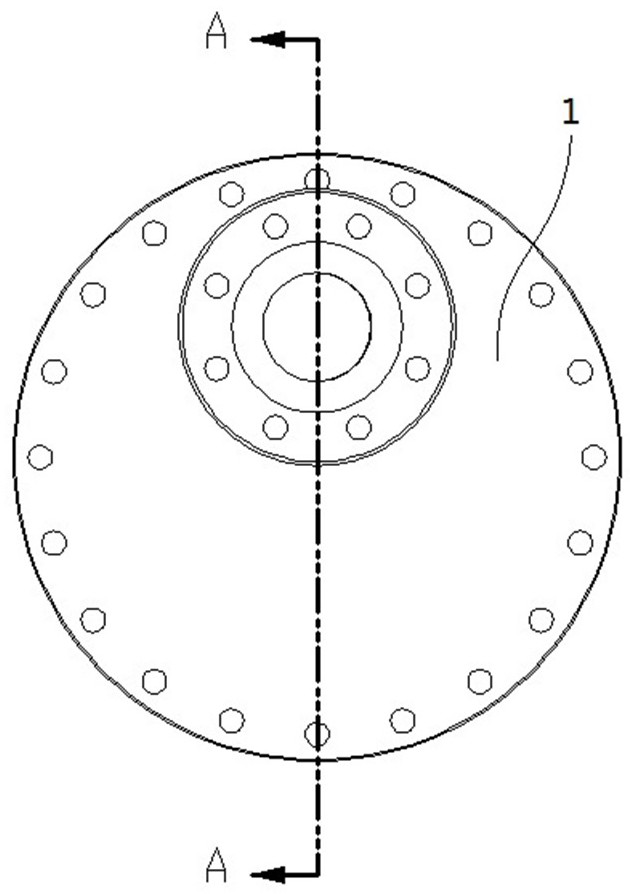

[0029] First, combine the Figure 1~5 Describe the new wear-resistant rotary valve according to the embodiment of the present invention, which is used for the circulation of various media in industrial production, and has a wide range of application scenarios.

[0030] Such as Figure 1~5 As shown, the novel wear-resistant rotary valve of the embodiment of the present invention has a first valve cover 1, a second valve cover 2, a first valve seat 3, a second valve seat 4, a valve plate 5, a valve plate sleeve 6, a valve pole 7. Wherein, the first valve cover 1 and the second valve cover 2 are arranged face to face by bolts, the first valve seat 3 is embedded in the first valve cover 1, the second valve seat 4 is embedded in the second valve cover 2, and the valve The plate sleeve 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com