Mixing and filtering integrated device and method for preparing yeast repair essence

A technology of essence and composite magnets, applied in the direction of mixing methods, chemical instruments and methods, mixers, etc., can solve the problems of uneven mixing, cumbersome operation, and numerous devices, achieve acceleration efficiency, simple operation process, and avoid transfer contact pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

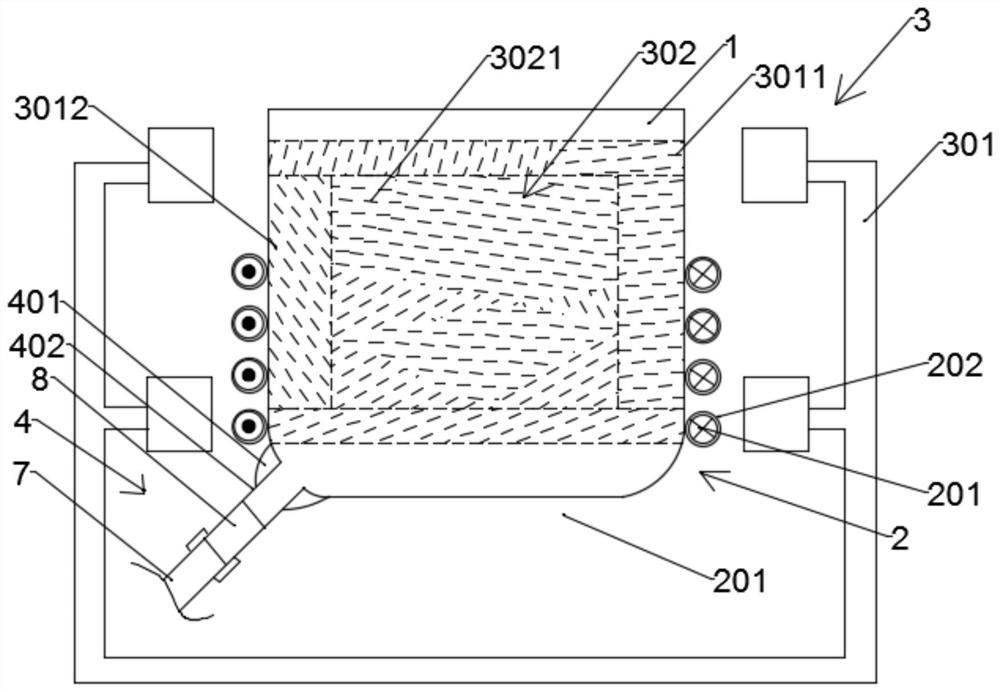

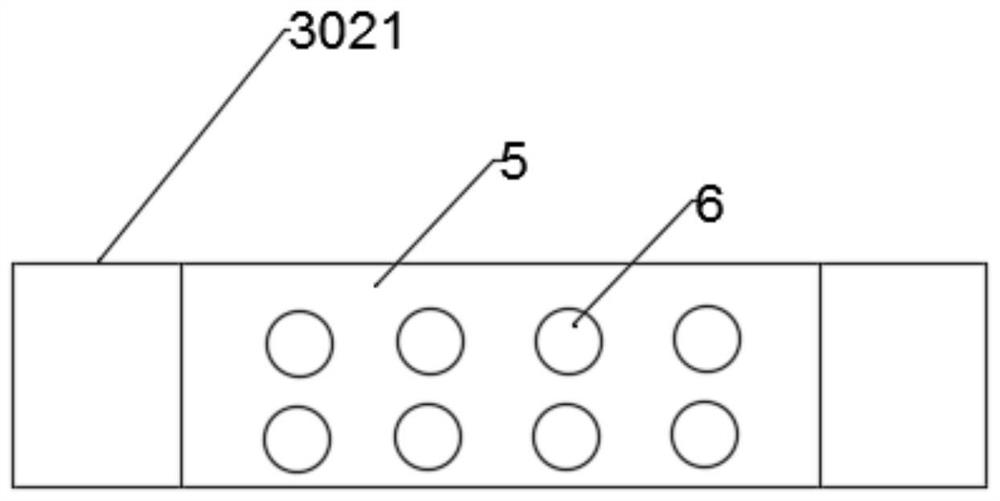

[0045] Such as figure 1 As shown, the present invention provides a mixing and filtering integrated device for making yeast repair essence, including a preparation tank 1, a heating ring 2 arranged on the outer wall of the preparation tank 1, and a liquid outlet pipeline 7 arranged at the lower end of the preparation tank 1 , a stirring and mixing mechanism 3 and a filtering mechanism 4 are arranged inside the preparation tank 1, the stirring and mixing mechanism 3 is arranged in the middle of the preparation tank 1, and the filtering mechanism 4 is arranged at the connection between the preparation tank 1 and the liquid outlet pipeline 7, and the yeast restoration essence The raw materials are mixed through the stirring and mixing mechanism 3, and then the particle residue is filtered through the filtering mechanism 4 to obtain the clarified yeast restoration essence.

[0046] Wherein, the raw material for preparing the yeast repair essence is a liquid mixture composed of yeas...

Embodiment 2

[0067] Based on the structure of the above mixing and filtering device, the present invention further provides a mixing and filtering method, which specifically includes the following steps:

[0068] S100, adding the preparation raw materials of the yeast restoration essence into the preparation tank, and adding the independent stirring rotor filled with the surfactant into the preparation tank to mix with the preparation raw materials of the yeast restoration essence;

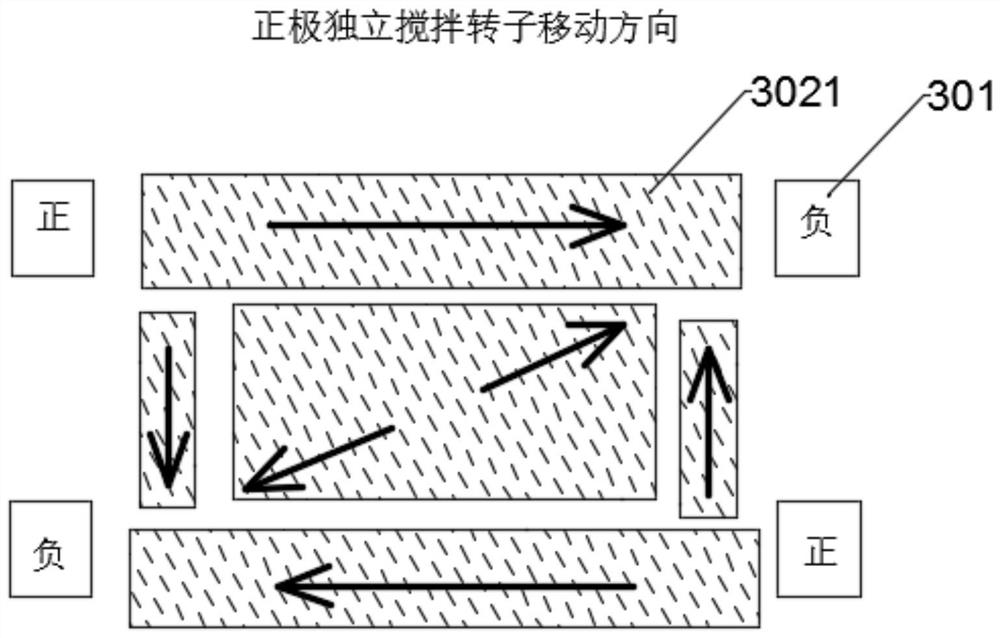

[0069] S200, start the heating mechanism, the independent stirring mechanism rotates irregularly under the action of the composite magnetic field, and releases the surfactant at the same time, driving the raw materials for the preparation of the yeast repair essence to be stirred and mixed under the action of the surfactant;

[0070] S300. After the mixing, the yeast repairing essence flows through the filter channel to obtain a clarified yeast repairing essence at the outlet pipe;

[0071] S400. Take out the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com