Environmentally friendly soil curing agent and preparation method

A soil stabilizer and environmental protection technology, applied in the field of environmental protection soil stabilizer and its preparation, can solve the problems of different soil strength, low permeability resistance, poor water resistance, etc., and achieve uniform soil hardness, the same degree of stirring, and enhanced Effects of Membrane Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

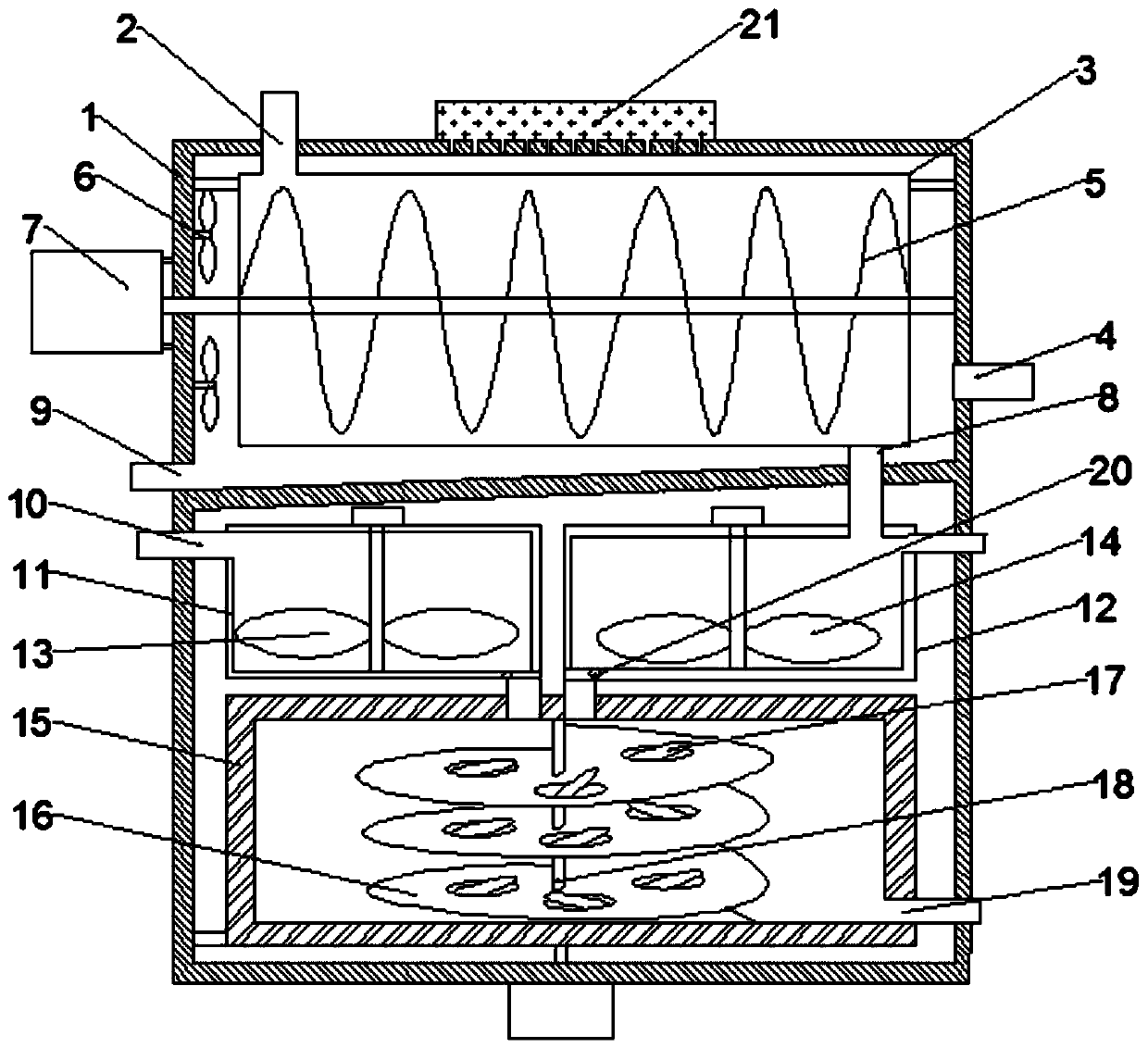

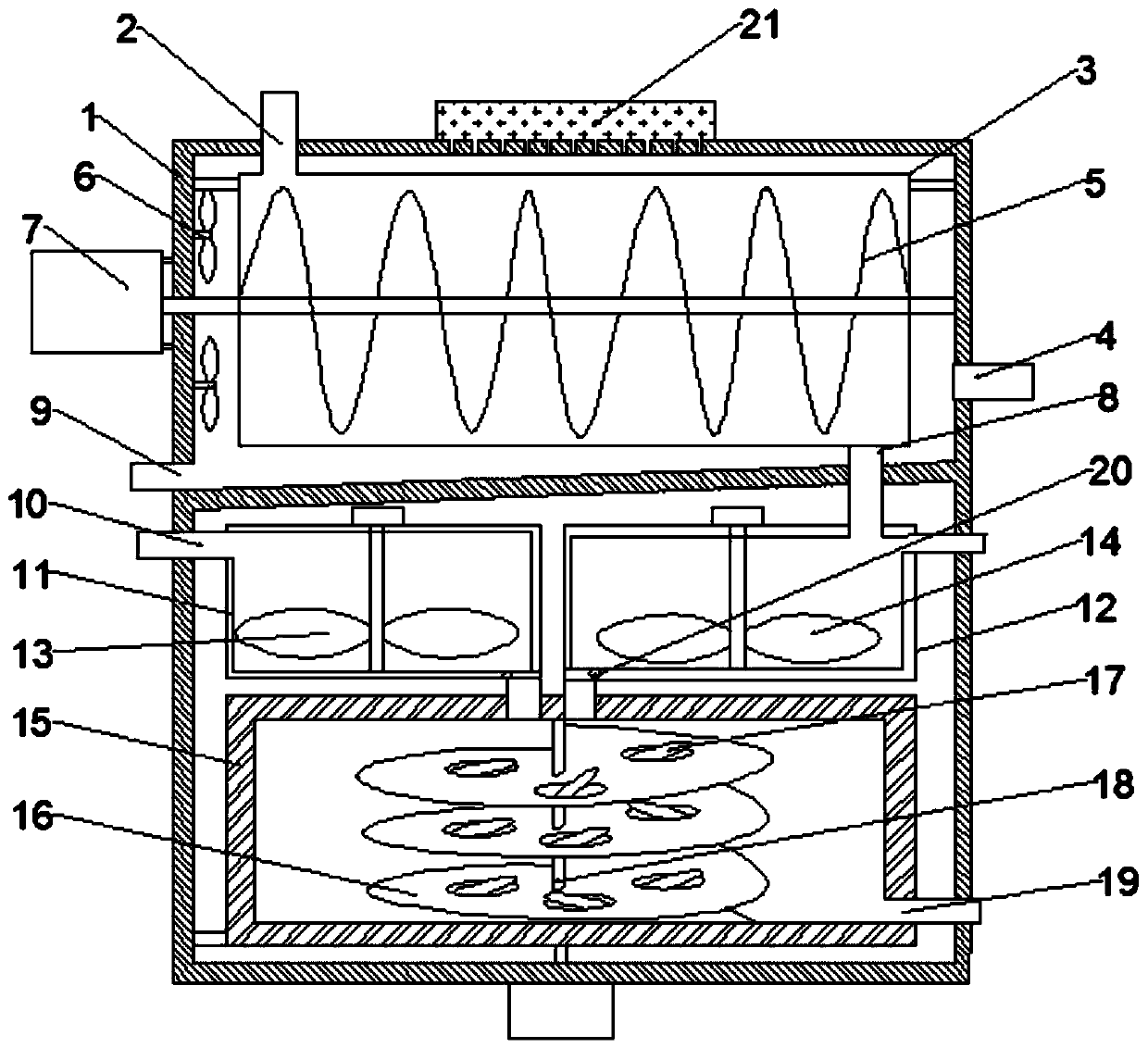

Method used

Image

Examples

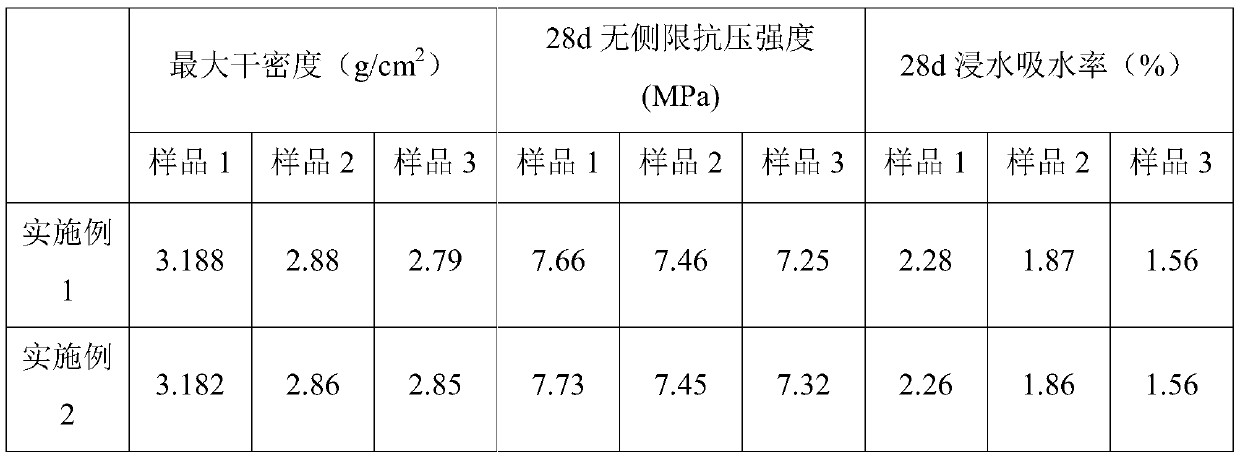

Embodiment 1

[0031] An environmentally friendly soil stabilizer comprising:

[0032] 30 parts of papermaking sludge, 15 parts of slag powder, 32 parts of sodium polyacrylate, 36 parts of glycerin, 26 parts of sulfonated oil, 18 parts of activator, 9 parts of oxidant, 10 parts of dispersant, 2 parts of polymer additive, surface 0.6 parts of active agent, 4 parts of lignin fiber, 10 parts of aminosilanol, 5 parts of water absorbent;

[0033] The specific preparation method is as follows: 30 parts of papermaking sludge, 15 parts of slag powder, 32 parts of sodium polyacrylate, 36 parts of glycerol, 26 parts of sulfonated oil, 18 parts of activator, 9 parts of oxidant, and dispersed 10 parts of agent, 2 parts of polymer additive, 0.6 part of surfactant, 4 parts of lignin fiber, 10 parts of aminosilanol, 5 parts of water-absorbing agent, stir and mix evenly to obtain an environmentally friendly soil curing agent;

[0034]Wherein, the activator is sodium chloride, the oxidant is sulfuric anhydr...

Embodiment 2

[0036] An environmentally friendly soil stabilizer comprising:

[0037] 30 parts of papermaking sludge, 15 parts of slag powder, 32 parts of sodium polyacrylate, 36 parts of glycerin, 26 parts of sulfonated oil, 18 parts of activator, 9 parts of oxidant, 10 parts of dispersant, 2 parts of polymer additive, surface 0.6 parts of active agent, 4 parts of lignin fiber, 10 parts of aminosilanol, 3 parts of water absorbent;

[0038] The specific preparation method is as follows: 30 parts of papermaking sludge, 15 parts of slag powder, 32 parts of sodium polyacrylate, 36 parts of glycerol, 26 parts of sulfonated oil, 18 parts of activator, 9 parts of oxidant, and dispersed 10 parts of agent, 2 parts of polymer additive, 0.6 part of surfactant, 4 parts of lignin fiber, 10 parts of aminosilanol, 3 parts of water-absorbing agent, stir and mix evenly to obtain an environmentally friendly soil curing agent;

[0039] Wherein, the activator is sodium sulfate, the oxidant is potassium perma...

Embodiment 3

[0041] An environmentally friendly soil stabilizer comprising:

[0042] 30 parts of papermaking sludge, 15 parts of slag powder, 32 parts of sodium polyacrylate, 36 parts of glycerin, 26 parts of sulfonated oil, 18 parts of activator, 9 parts of oxidant, 10 parts of dispersant, 2 parts of polymer additive, surface 0.6 parts of active agent, 4 parts of lignin fiber, 10 parts of aminosilanol, 4 parts of water absorbent;

[0043] The specific preparation method is as follows: 30 parts of papermaking sludge, 15 parts of slag powder, 32 parts of sodium polyacrylate, 36 parts of glycerol, 26 parts of sulfonated oil, 18 parts of activator, 9 parts of oxidant, and dispersed 10 parts of agent, 2 parts of polymer additive, 0.6 part of surfactant, 4 parts of lignin fiber, 10 parts of aminosilanol, 4 parts of water-absorbing agent, stir and mix evenly to obtain an environmentally friendly soil curing agent;

[0044] Wherein, the activator is sodium sulfate, the oxidant is potassium perma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com