Gear grinding machine

A gear grinding machine and internal gear technology, which is applied in the field of gear grinding machines, can solve the problems of operation site use and large overall size of the gear grinding machine, and achieve the effect of reducing floor space, compact structure and reducing overall size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

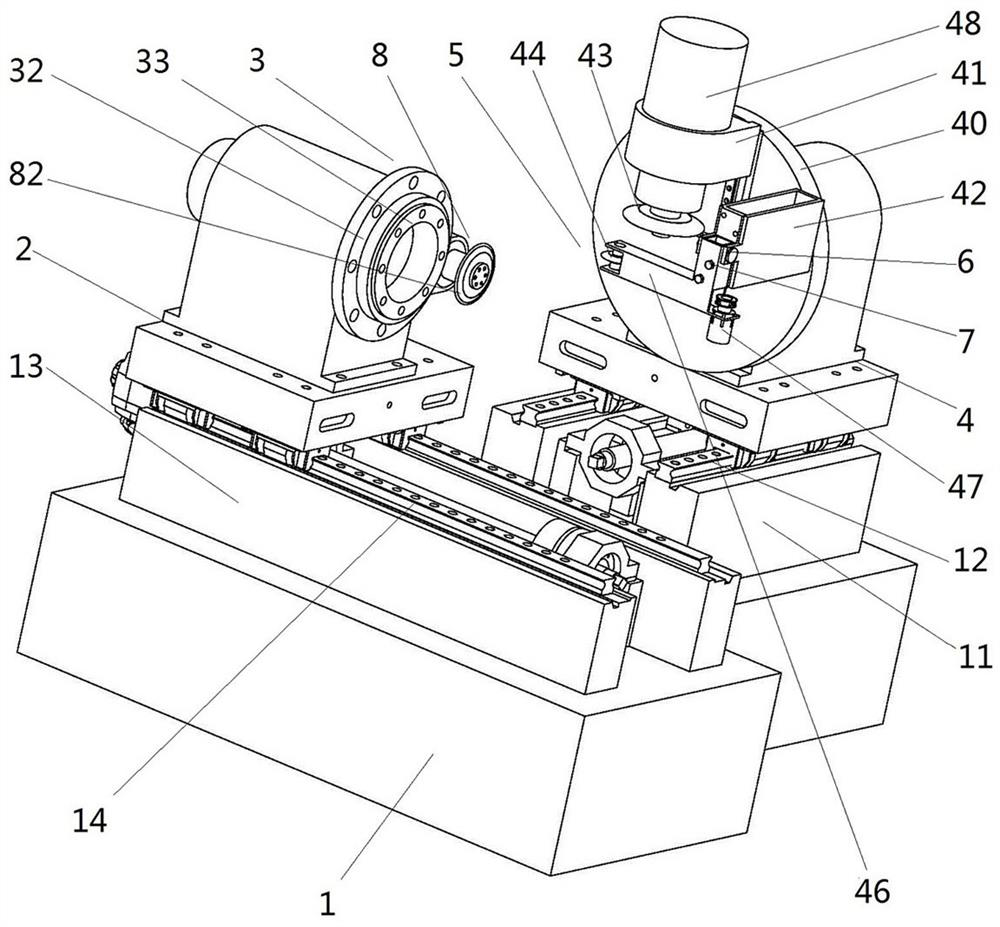

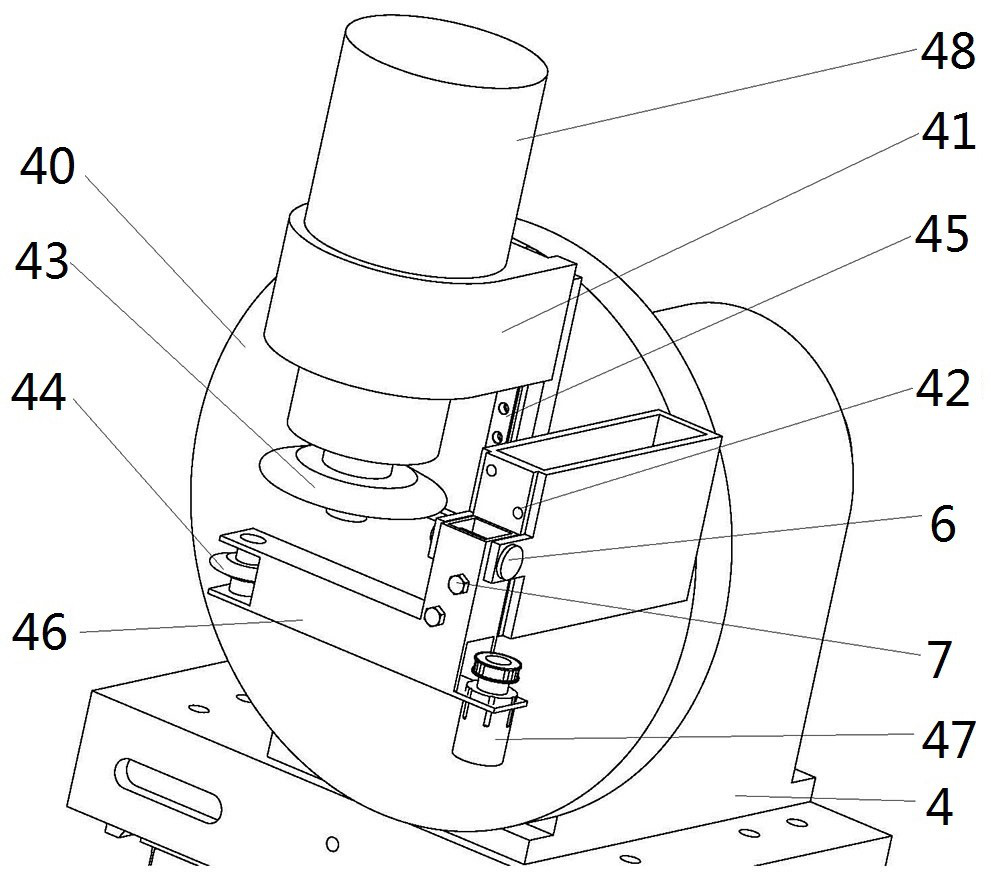

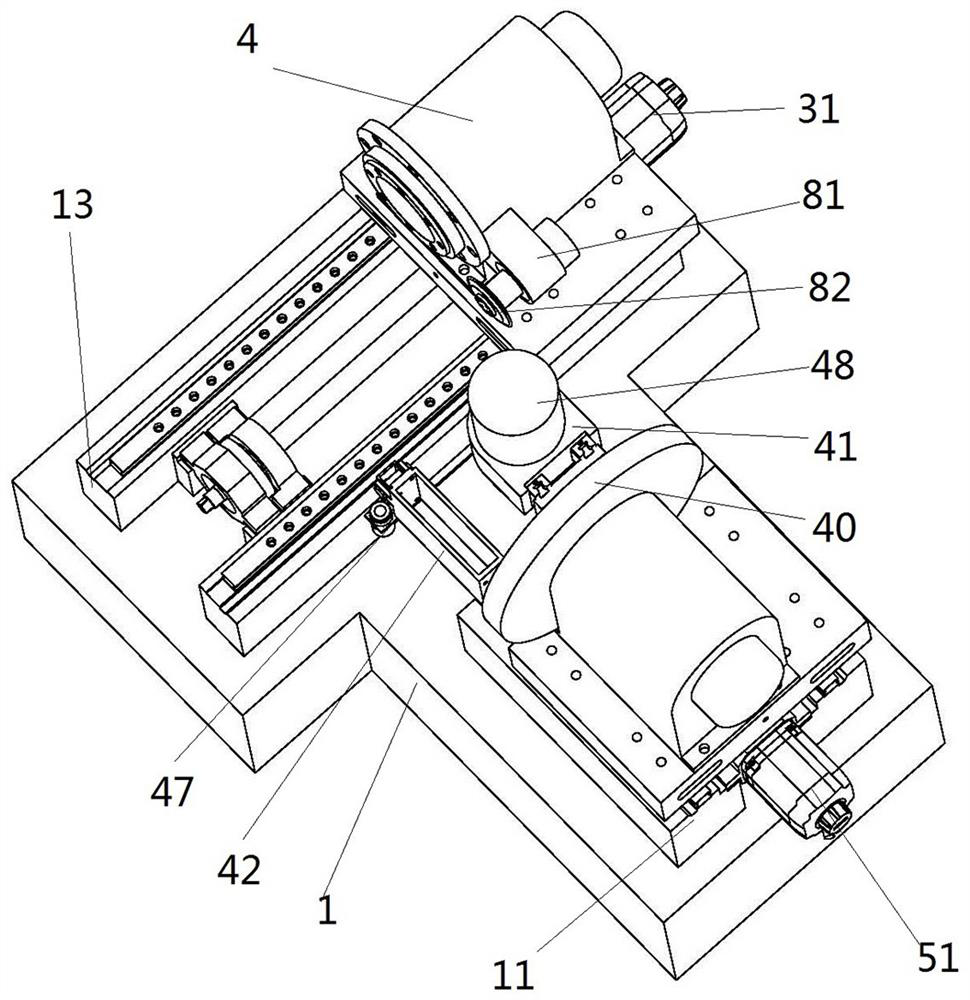

[0051] like figure 1 , image 3 and Figure 5 As shown, the gear grinding machine includes a base 1, a workpiece mechanism slide 2, a workpiece mechanism 3, a grinding wheel mechanism slide 5, and a grinding wheel mechanism 4. The workpiece mechanism slide 2 is guided and slidably installed on the base 1 along the front and rear directions, and the workpiece mechanism 3 is installed on the slide table 2 of the workpiece mechanism; the slide table 5 of the grinding wheel mechanism is guided and slid on the base 1 along the left and right directions, and the grinding wheel mechanism 4 is installed on the slide table 5 of the grinding wheel mechanism. The workpiece mechanism 3 is used for installing the workpiece to be processed, and the grinding wheel mechanism 4 is used for installing the grinding wheel for grinding the workpiece to be processed.

[0052] Specifically, the front and rear directions correspond to the X direction, the left and right directions correspond to the...

specific Embodiment 2

[0067]The main difference between it and the above-mentioned embodiment 1 is that in the above-mentioned embodiment 1, the external tooth mounting seat is in the working position or the avoidance position by sliding up and down. In this embodiment, the external gear mounting base is hinged to the grinding wheel turret, and the hinge shaft extends along the front and rear directions. At this time, the external gear mounting base is in the working position or the avoidance position by swinging.

specific Embodiment 3

[0069] The difference between it and the above-mentioned embodiment 1 mainly lies in that in the above-mentioned embodiment 1, the internal tooth mounting seat is in the working position or the avoidance position by swinging. In this embodiment, the inner tooth swing arm is guided and slid up and down and installed on the grinding wheel turntable, and the inner tooth mounting seat is in the working position or the avoidance position by swinging.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap