Glass processing device combining water knife and processing center

A processing center and processing device technology, applied in used abrasive processing devices, glass production, metal processing equipment, etc., can solve problems such as poor automation, high impact force, scratched glass, etc., and achieve yield and processing Efficiency improvement, good fixation effect and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

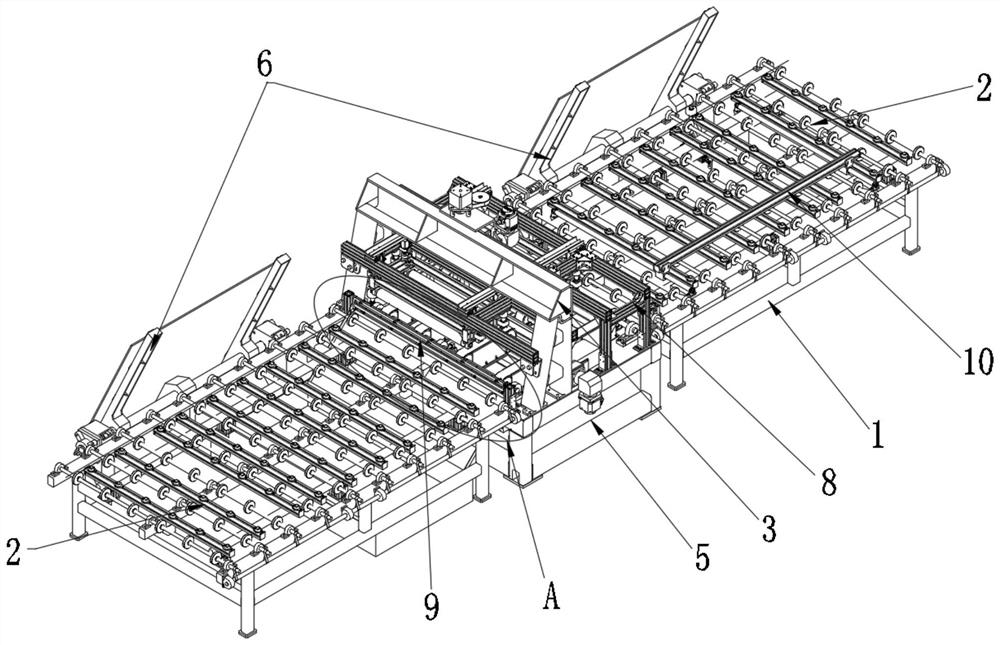

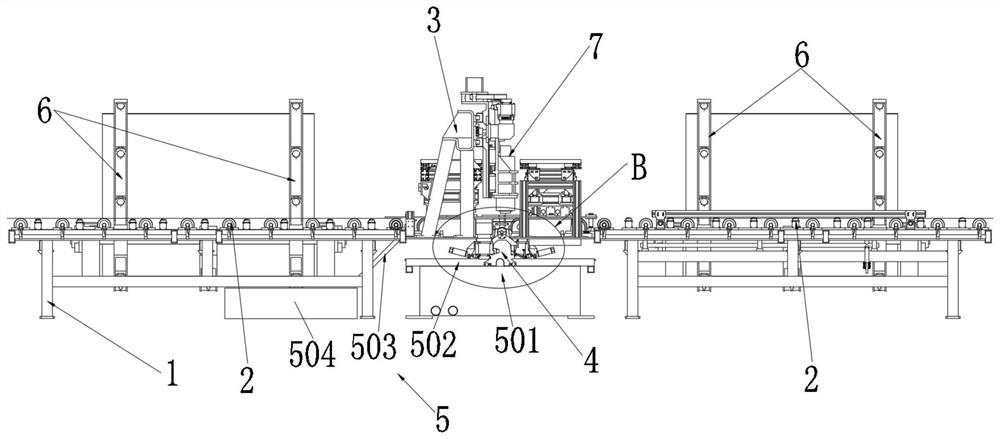

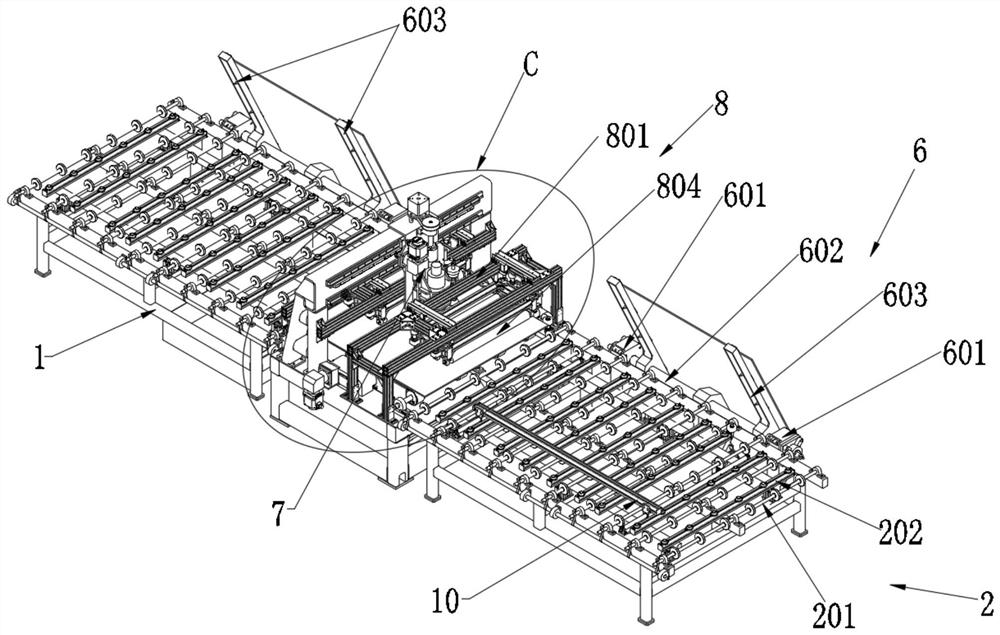

[0039] Such as Figures 1 to 12 As shown, the glass processing device combined with the water jet and the processing center in this embodiment includes a frame 1 arranged in the horizontal direction, a feeding rack 2 arranged above the rack 1 for conveying glass, and a feeding rack 2 arranged on the feeding rack 2. The X-axis bending beam assembly 3 arranged above and perpendicular to the frame 1 along the horizontal direction, the blanking and sand-retaining device 4 arranged under the frame 1, and the Z-axis that is slidingly connected with the X-axis bending beam assembly 3 and used for processing Processing assembly 7, a pressing device 8 for pressing glass and a washing device 9 for washing processed glass; X-axis bending beam assembly 3 includes a beam main body arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com