Single-cavity frameless laminated double-glass assembly and laminating method thereof

A double-glass module, single-chamber technology, applied in the directions of lamination, lamination devices, chemical instruments and methods, etc., can solve the problems of increasing manpower, affecting the use of components, contaminating glass, etc., to solve the problem of cracks and increase the force. The effect of buffering and reducing the cost of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

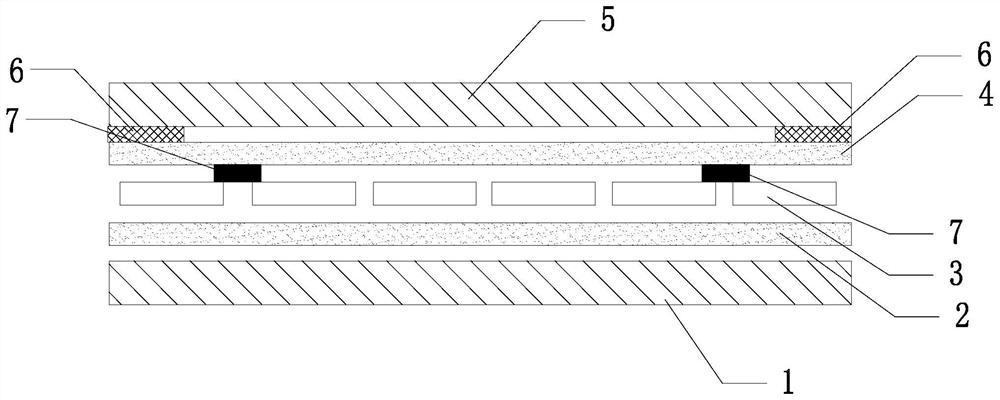

[0043] A double-glass component single-cavity frameless laminated double-glass component and a lamination method thereof, the method comprising:

[0044] (1) Firstly, the solar cells are serially welded to form a solar cell string, and the POE film is cut to obtain the POE film layer and the POE film pad;

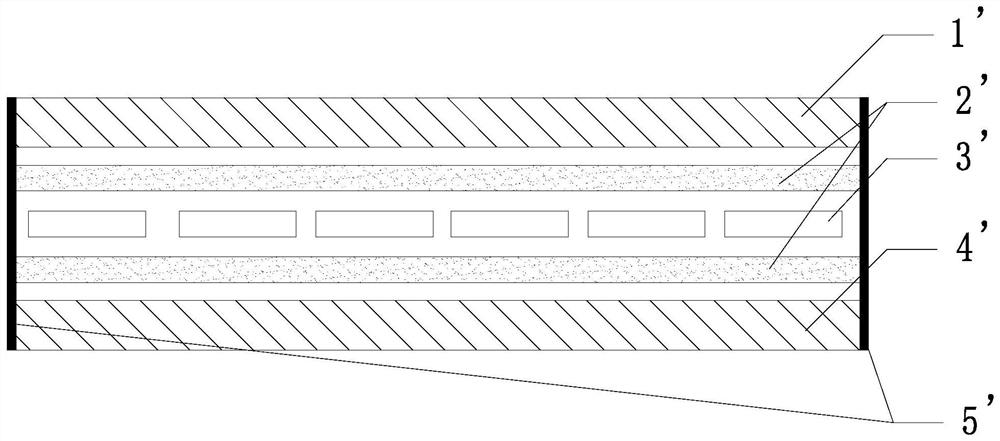

[0045] (2) Lay POE film pads on the four corners of the back glass layer, then lay the second POE film layer, and then lay the solar cell string layer bonded with hard tape on the second POE film layer, The first POE adhesive film layer is laid on the solar cell string layer, and then the front glass layer is laid to form a solar double glass module; The spacing between solar battery strings is greater than the spacing between every two adjacent strings of non-edge solar battery strings;

[0046] (3) When laying solar cell strings, the distance between the solar cell strings located at the edge positions on both sides of the module and the respective adjacent solar cell st...

Embodiment 2

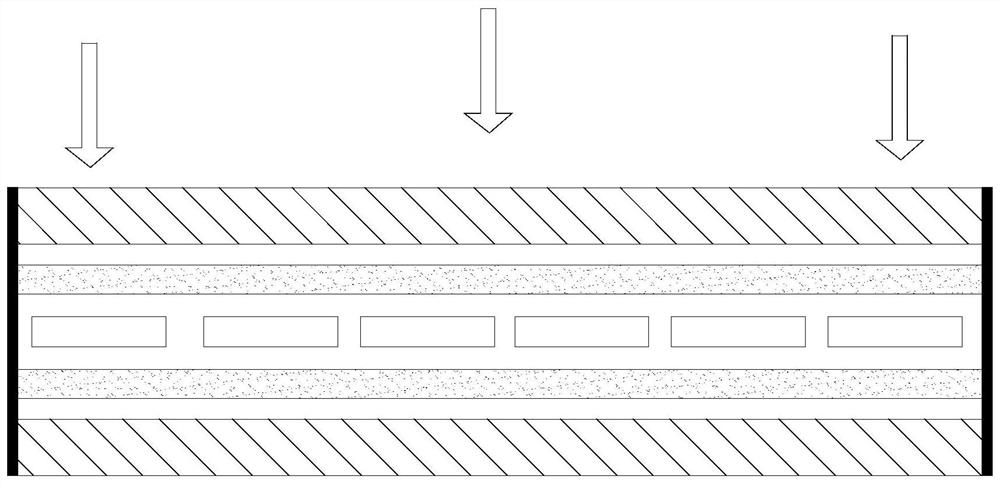

[0050] The present application also provides a single-cavity frameless laminated double-glass component of a double-glass component and a lamination method thereof, the method comprising:

[0051] (1) Firstly, the solar cells are serially welded to form a solar cell string, and the POE film is cut to obtain the POE film layer and the POE film pad;

[0052] (2) Lay POE film pads on the four corners of the back glass layer, then lay the second POE film layer, and then lay the solar cell string layer bonded with hard tape on the second POE film layer, The first POE adhesive film layer is laid on the solar cell string layer, and then the front glass layer is laid to form a solar double glass module; The spacing between solar battery strings is greater than the spacing between every two adjacent strings of non-edge solar battery strings;

[0053] (3) When laying solar cell strings, the distance between the solar cell strings located at the edge positions on both sides of the modul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com