A kind of preparation method of yttrium lutetium cerium oxide for scintillation crystal

A scintillation crystal, yttrium oxide technology, applied in rare earth metal oxide/hydroxide and other directions, can solve the problems of restricting the application and development of downstream industries, unreasonable product cost performance, unclear rare earth oxide product standards, etc. Controlled equipment, low cost and uniform distribution of rare earth elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of yttrium lutetium cerium oxide for scintillation crystal of the present invention, wherein the general chemical formula of yttrium lutetium cerium oxide is: (Y y Lu (1-x-y) ) 2 o 3 : xCe, where x=0.001~0.01, y=0.05~0.3;

[0030] Step 1: According to the stoichiometric ratio of the three rare earth elements of yttrium, lutetium and cerium in the general chemical formula, mix the hydrochloric acid or nitric acid stripping solution of the three rare earth ions evenly, adjust the pH of the solution to 2-3 with ammonia water, and heat to 80°C , to obtain a solution.

[0031] Step 2: prepare an oxalic acid solution according to the molar ratio of the rare earth to the precipitating agent oxalic acid of 1:1.8-2.2, and heat the oxalic acid solution to 80°C to obtain b solution;

[0032] Step 3: under stirring conditions, slowly add solution a to solution b, stir for 30 minutes, leave to age for 3 to 6 hours, and filter to obtain the precipitate of y...

Embodiment 1

[0035] Embodiment 1 (Y 0.15 Lu 0.849 ) 2 o 3 :1‰Ce preparation

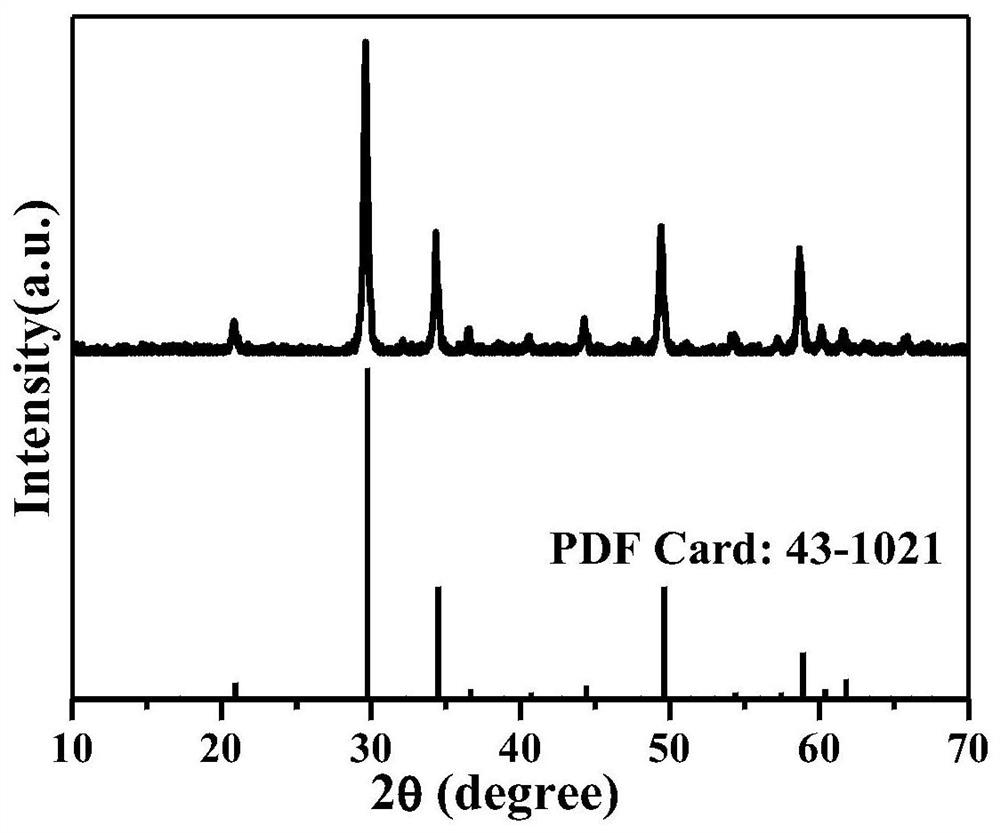

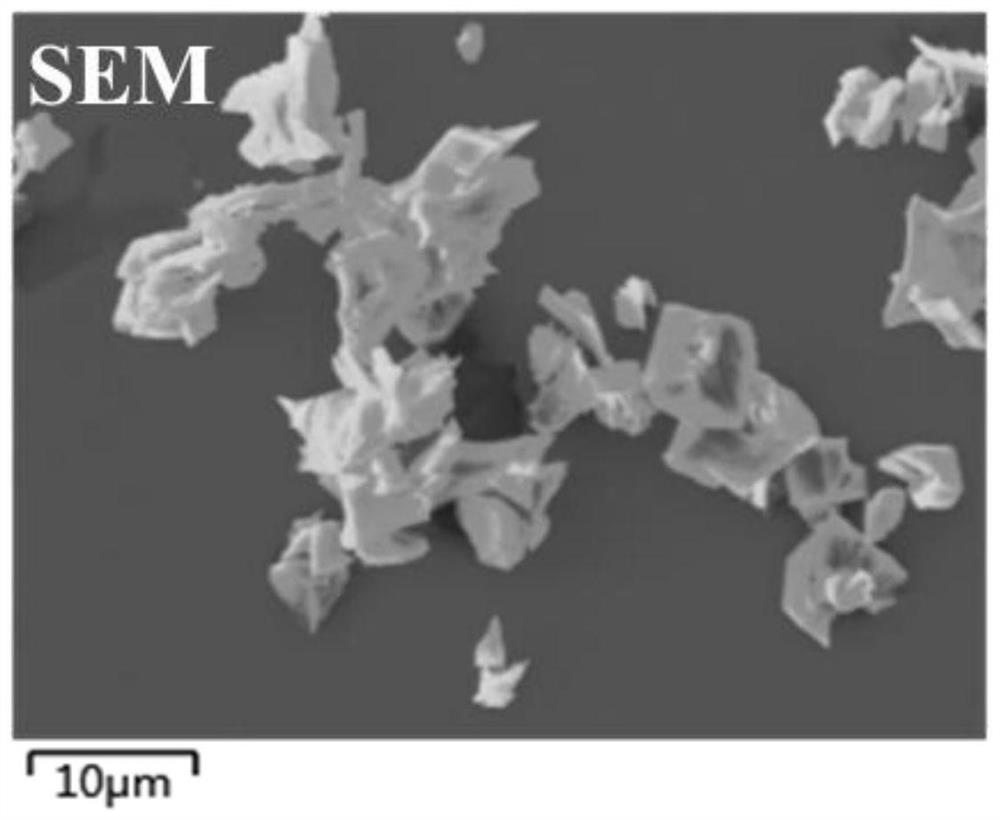

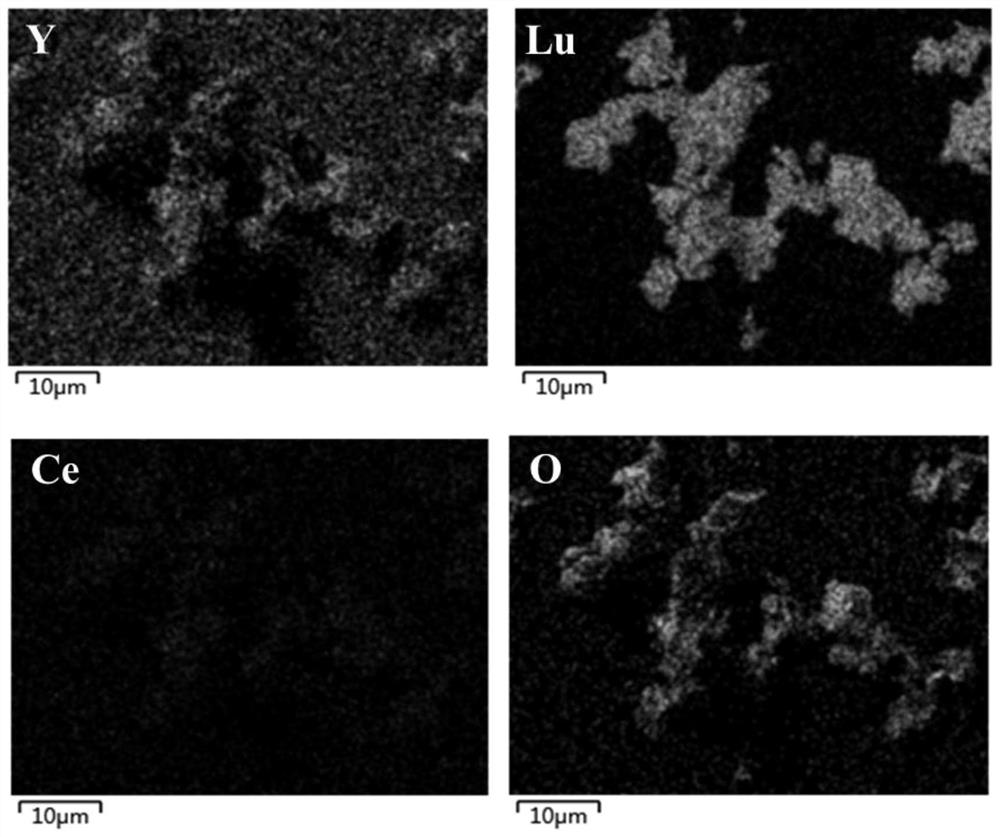

[0036] According to yttrium, lutetium and cerium accounting for 15%, 84.9% and 0.1% of the total rare earth, mix the yttrium chloride, lutetium chloride and cerium chloride stripping solution with the total rare earth being 0.01mol evenly, and adjust the pH value of the solution with ammonia water 2.00, heat the solution to 80°C; prepare 0.018mol oxalic acid solution, heat the solution to 80°C; under the condition of magnetic stirring, slowly add the above mixed rare earth solution into the oxalic acid solution, stir for 30min, and let it stand for 3h; Precipitate and filter to obtain solid yttrium-lutetium-cerium oxalate, and burn in a muffle furnace at 900°C for 3 hours to obtain yttrium-lutetium-cerium oxide powder. figure 1 The XRD pattern of this sample is consistent with the JCPDS standard card (43-1021) of lutetium oxide. figure 2 For the SEM of this sample, image 3 is the mapping spectrum of the s...

Embodiment 2

[0037] Embodiment 2 (Y 0.05 Lu 0.945 ) 2 o 3 :5‰Ce preparation

[0038] According to yttrium, lutetium and cerium accounting for 5%, 94.5% and 0.5% of the total rare earth, the total rare earth is 0.01mol yttrium chloride, lutetium chloride and cerium chloride stripping solution are mixed evenly, and the pH value of the solution is adjusted with ammonia water To 3.00, heat the solution to 80°C; prepare 0.02mol oxalic acid solution, heat the solution to 80°C; under the condition of magnetic stirring, slowly add the above mixed rare earth solution into the oxalic acid solution, stir for 30min, and let it stand for 4h; Precipitate and filter to obtain solid yttrium-lutetium-cerium oxalate, and burn in a muffle furnace at 1200°C for 2 hours to obtain yttrium-lutetium-cerium oxide powder.

[0039] The yttrium lutetium cerium oxide powder prepared in the above examples has the advantages of uniform distribution of rare earth elements, etc., and can meet the requirements of scint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com