A wireless charging magnetic core for smart watches and its preparation method

A technology for wireless charging and smart watches, applied in transformer/inductor magnetic cores, circuits, inductors, etc., can solve the problems of strength and toughness, small volume, low loss, etc., achieve optimized particle size distribution, small deformation, and improve temperature characteristics and the effect of high frequency eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

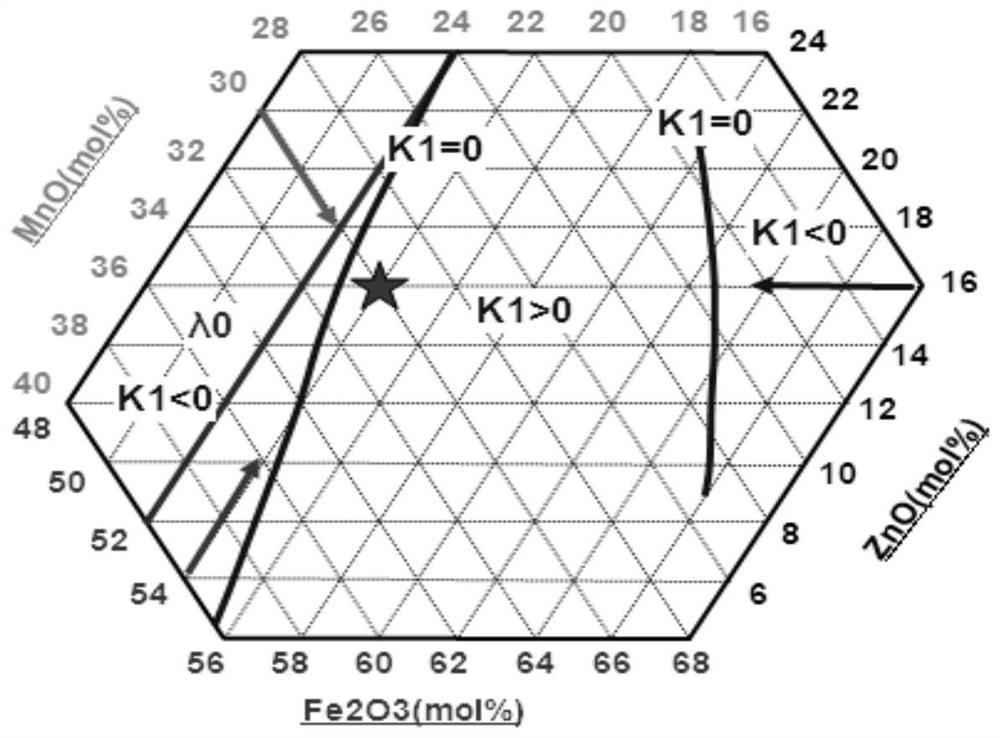

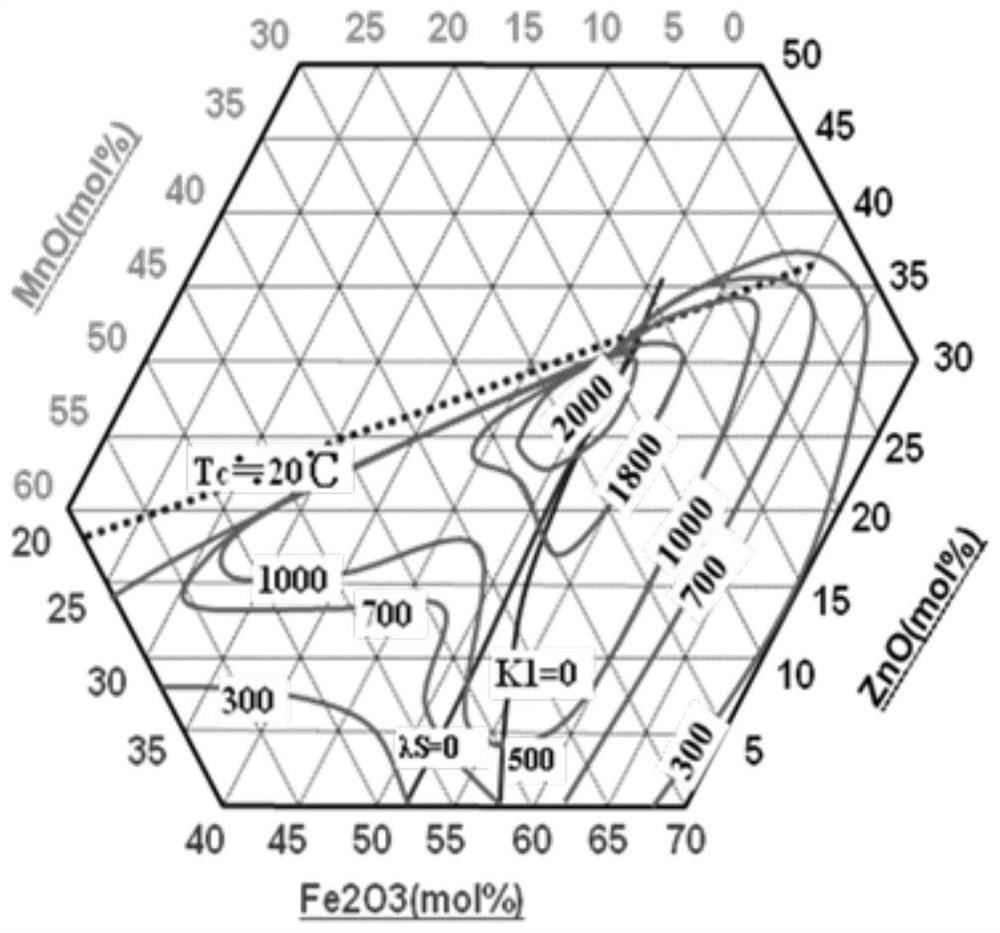

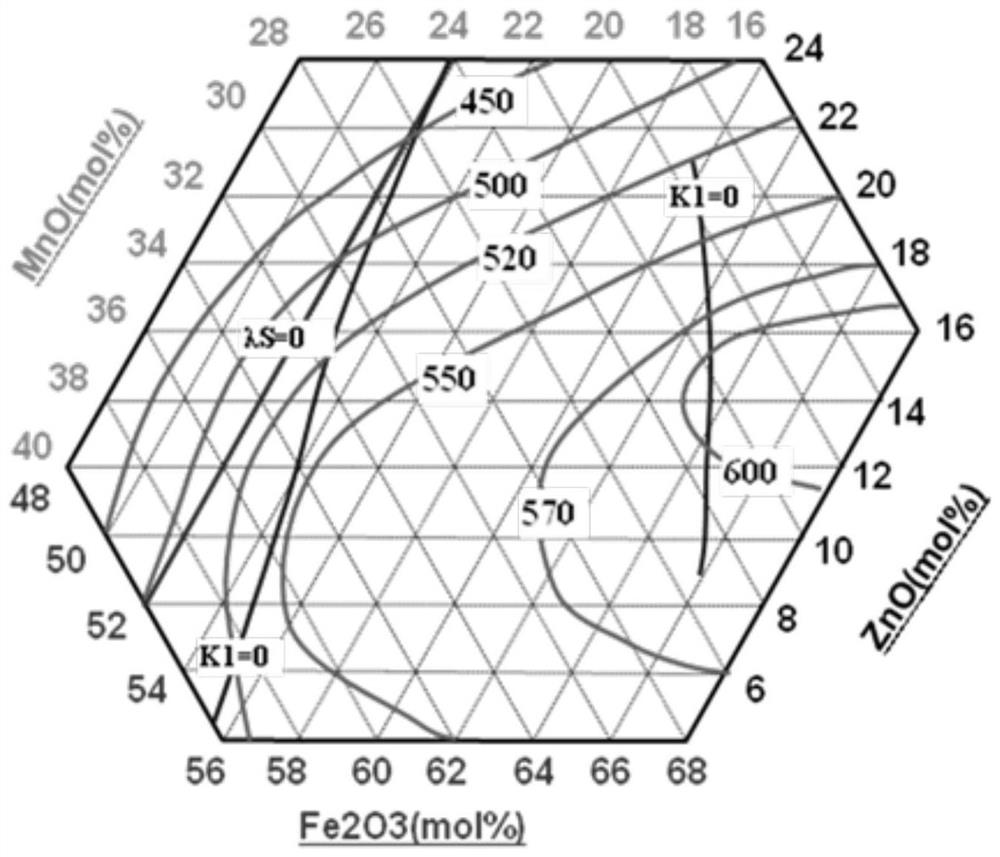

[0073] A wireless charging magnetic core for a smart watch, the raw material includes a main component and an additive, and the main component includes 52.5% Fe in molar percentage 2 o 3 , 11% of ZnO and 36.5% of MnO; additives include 400ppm of V 2 o 5 , 100ppm MoO 3 , 3000ppm of Co 2 o 3 , 500ppm of CaCO 3 and 300ppm Nb 2 o 5 .

[0074] The preparation method of the above-mentioned wireless charging magnetic core for smart watches comprises the following steps:

[0075] (1) Ingredients: Weigh the main ingredients in proportion, mix and stir for 30 minutes and vibrate for 30 minutes, then centrifugally granulate to obtain the main ingredients;

[0076] (2) Pre-burning: the main material is pre-fired at 940°C to obtain pre-fired material;

[0077] (3) Secondary sand grinding: put the calcined material into the sand mill and add additives and deionized water, and obtain the secondary sand abrasive after 140 min of secondary sand grinding;

[0078] (4) Centrifugal gra...

Embodiment 2

[0082] A wireless charging magnetic core for a smart watch, the raw material includes a main component and an additive, and the main component includes 51.5% Fe in molar percentage2 o 3 , 12.5% of ZnO and 36% of MnO; additives include 100ppm of V 2 o 5 , 2000ppm of Co 2 o 3 , 100ppm of CaCO 3 and 100ppm Nb 2 o 5 .

[0083] The preparation method of the above-mentioned wireless charging magnetic core for smart watches comprises the following steps:

[0084] (1) Ingredients: Weigh the main ingredients in proportion, mix and stir for 25 minutes and vibrate for 35 minutes, then centrifugally granulate to obtain the main ingredients;

[0085] (2) Pre-burning: the main material is pre-fired at 930°C to obtain pre-fired material;

[0086] (3) Secondary sand grinding: Put the calcined material into the sand mill and add additives and deionized water, and obtain the secondary sand abrasive after 130 minutes of secondary sand grinding;

[0087] (4) Centrifugal granulation: ad...

Embodiment 3

[0091] A wireless charging magnetic core for a smart watch, the raw material includes a main component and an additive, and the main component includes 53.5% Fe in molar percentage 2 o 3 , 9.0% of ZnO and 37.5% of MnO; additives include 600ppm of V 2 o 5 , 200ppm MoO 3 , 4500ppm of Co 2 o 3 , 1000ppm of CaCO 3 and 500ppm Nb 2 o 5 .

[0092] The preparation method of the above-mentioned wireless charging magnetic core for smart watches comprises the following steps:

[0093] (1) Ingredients: Weigh the main ingredients in proportion, mix and stir for 35 minutes and vibrate for 25 minutes, then centrifugally granulate to obtain the main ingredients;

[0094] (2) Pre-burning: the main material is pre-fired at 950°C to obtain pre-fired material;

[0095] (3) Secondary sand grinding: put the calcined material into the sand mill, add additives and deionized water, and obtain the secondary sand abrasive after the second sand grinding for 150min;

[0096] (4) Centrifugal gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com