A kind of mixed antibacterial polyurethane and preparation method thereof

A technology of polyurethane and diisocyanate, which is applied in the field of polyurethane, can solve the problems that stabilizers and colorants are susceptible to microbial attack, and achieve the effect of improving plasticizing performance and good tensile performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

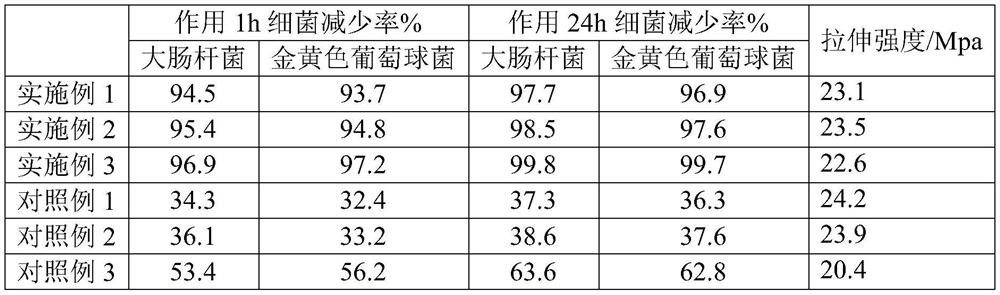

Examples

Embodiment 1

[0024] A preparation method for mixing antibacterial polyurethane, comprising the following steps:

[0025] (1) Polyoxypropylene triol 24g of molecular weight 1000, polyoxypropylene diol 24g of molecular weight 2000, poly-1,4-hexamethylene succinate diol 18.5g of molecular weight 2000, polytetrahydrofuran ether diol 25g of molecular weight 1000 Stir and mix evenly, then heat to 80°C for 40min under vacuum at -0.1Mpa.

[0026] (2) Cool the solution in step (1) to 70°C, add 83.6g of toluene diisocyanate and 2.3g of dibutyltin dilaurate, stir evenly, and react at -0.1Mpa for 30min;

[0027] (3) Add 18.6 g of phenyl salicylate and 11.6 g of sodium hexafluoroaluminate to the mixed solution after the reaction in step (2), and react at -0.1Mpa at 90°C for 40 minutes; obtain a prepolymer solution;

[0028] (4) Then, 0.9 g of trimethylolpropane and 4.3 g of methyltriethoxysilane were added to the pre-polymerization solution, and the reaction was continued at 110° C. for 40 min to obta...

Embodiment 2

[0030] A preparation method for mixing antibacterial polyurethane, comprising the following steps:

[0031] (1) Polyoxypropylene triol 27g of molecular weight 1000, polyoxypropylene diol 22g of molecular weight 2000, molecular weight 2000 poly-1,4-hexamethylene succinate diol 16g, molecular weight 1000 polytetrahydrofuran ether glycol 28g stir Mix well, then heat to 85°C under -0.1Mpa and vacuum dehydrate for 50min.

[0032] (2) Cool the solution in step (1) to 65°C, add 86g of cyclohexyl diisocyanate and 2.7g of dibutyltin dilaurate, stir evenly, and react at -0.1Mpa for 40min;

[0033] (3) Add 16 g of phenyl salicylate and 14 g of sodium hexafluoroaluminate to the mixed solution after the reaction in step (2), and react at -0.1Mpa at 95°C for 35 minutes; obtain a prepolymer solution;

[0034] (4) Then, 0.7 g of trimethylolpropane and 5.5 g of methyltriethoxysilane were added to the pre-polymerization solution, and the reaction was continued at 105° C. for 45 minutes to obta...

Embodiment 3

[0036] A preparation method for mixing antibacterial polyurethane, comprising the following steps:

[0037] (1) polyoxypropylene triol 28g of molecular weight 1000, polyoxypropylene glycol 25g of molecular weight 2000, molecular weight 2000 poly-1,4-hexamethylene succinate diol 15g, molecular weight 1000 polytetrahydrofuran ether glycol 26g stir Mix well, then heat to 70°C under -0.1Mpa and vacuum dehydrate for 45min.

[0038] (2) Cool the solution in step (1) to 70°C, add 84.8g of isophorone diisocyanate and 2.2g of dibutyltin dilaurate, stir evenly, and react at -0.1Mpa for 35min;

[0039] (3) Add 17g of phenyl salicylate, 3.6g of zinc stearate, and 11g of sodium hexafluoroaluminate to the mixed solution after the reaction in step (2), and react at -0.1Mpa at 95°C for 40min; liquid;

[0040] (4) Then, add 0.8 g of trimethylolpropane and 5 g of methyltriethoxysilane to the prepolymerization solution, and continue to react at 110° C. for 50 min to obtain mixed antibacterial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com