Method for heating solution containing HCFO-1233zd(E) in absorber

An absorber and heat-absorbing technology, applied in sorption machines, heat pumps, refrigerators, etc., can solve problems such as poor heat transfer temperature difference matching, high pressure requirements for heat exchange equipment, and lower pressure requirements for equipment to achieve stable performance. , the effect of excellent thermodynamic performance and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

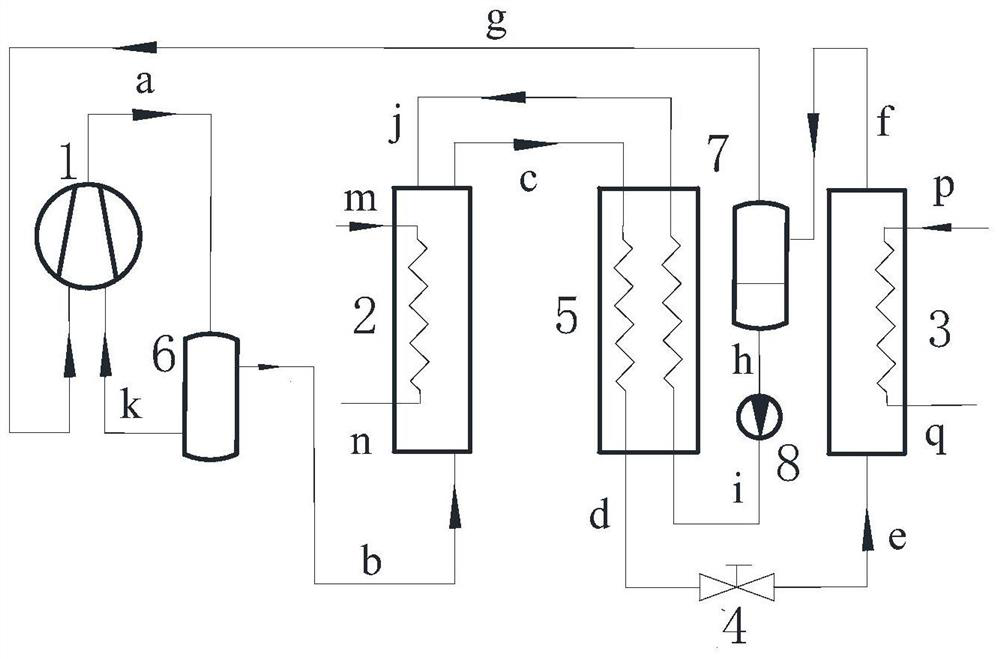

[0033] Such as figure 1 As shown, in the system described in this embodiment, the air outlet of the compressor 1 is connected to the air inlet of the oil separator 6, the air outlet of the oil separator 6 is connected to the air inlet of the absorber 2, and the solution outlet of the absorber 2 is connected to the air inlet of the absorber 2. The first inlet of the solution heat exchanger 5 is connected, the first outlet of the solution heat exchanger 5 is connected with the solution inlet of the desorber 3 through the expansion device 4, the solution outlet of the desorber 3 is connected with the inlet of the gas-liquid separator 7, and the gas-liquid The gas outlet of the separator 7 is connected with the air inlet of the compressor 1, the liquid outlet of the gas-liquid separator 7 is connected with the second inlet of the solution heat exchanger 5, and the second outlet of the solution heat exchanger 5 is connected with the absorber 2 The solution inlet is connected.

[0...

Embodiment 2

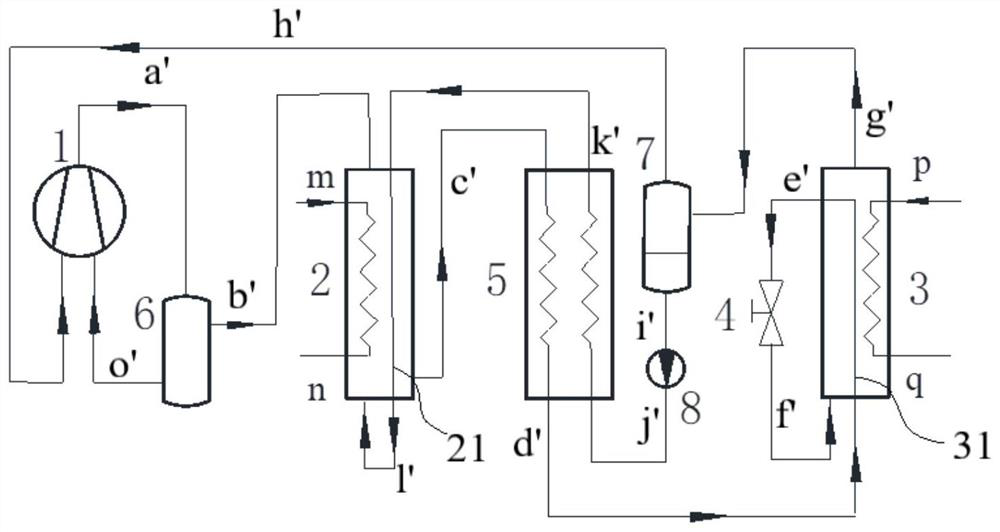

[0037] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that a superheated pipeline 21 is provided in the absorber 2 , and a supercooled pipeline 31 is provided in the desorber 3 . The workflow is as follows:

[0038] The mixture a' containing HCFO-1233zd(E) and lubricating oil at the outlet of compressor 1 enters the oil separator 6, and the lubricating oil separated by the oil separator 6 passes through the liquid outlet and is decompressed into o' to return to the compressor, so The steam b' containing HCFO-1233zd(E) at the gas outlet of the oil separator 6 enters the absorber 2; the outlet of the solution heat exchanger 5 can absorb the absorbent k' of HCFO-1233zd(E) first in the absorber 2 Preheated to l', and then enter the absorber 2, in the absorber 2, the steam b' is absorbed by the absorbent l', release heat of absorption, and at the same time the heat transfer medium or refrigerant in the absorber 2 Or the subject m to be heat...

Embodiment 3

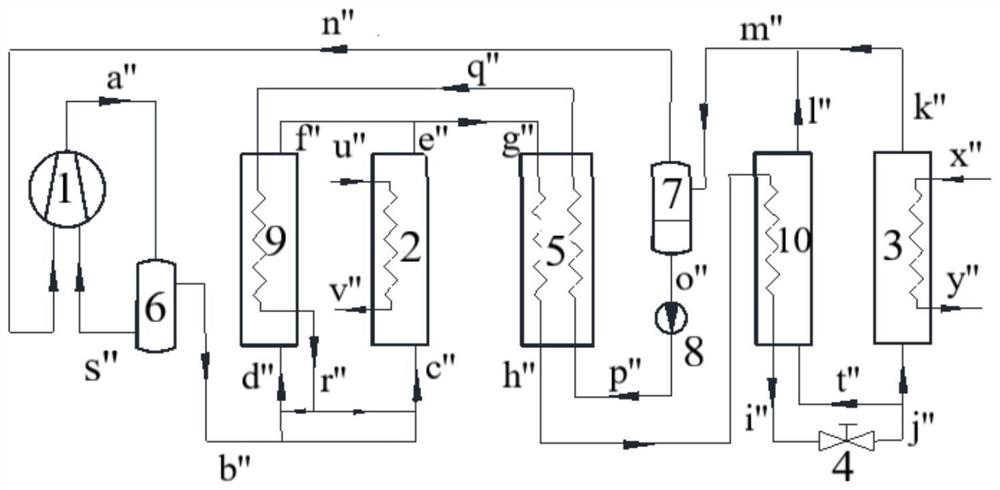

[0041] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that it also includes a superheater 9 and a subcooler 10, the superheater 9 is arranged between the oil separator 6 and the heat absorber 2, and the subcooler 10 is arranged between the desorption Between device 3 and gas-liquid separator 7. The workflow is as follows:

[0042] The mixture a" containing HCFO-1233zd(E) and lubricating oil at the outlet of compressor 1 enters the oil separator 6, and the lubricating oil separated by the oil separator 6 passes through the liquid outlet and is decompressed into s" and returns to the compressor. The steam b" containing HCFO-1233zd(E) at the gas outlet of the oil separator 6 is divided into two parts, one part enters the absorber 2, and in the absorber 2, HCFO-1233zd(E) can be absorbed from the outlet of the superheater 9 The absorbent r" absorbs and releases the heat of absorption. At the same time, the heat transfer medium or refrigerant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com