Blast furnace digital twinning system based on Unity 3D

A blast furnace and twinning technology, applied in the field of 3D visualization, can solve problems such as unpredictability of problems, ambiguity of experience, and difficulty in grasping, and achieve the effect of accelerating understanding and optimizing design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The invention is further illustrated in connection with the examples, but is not as a basis for the limitation of the invention.

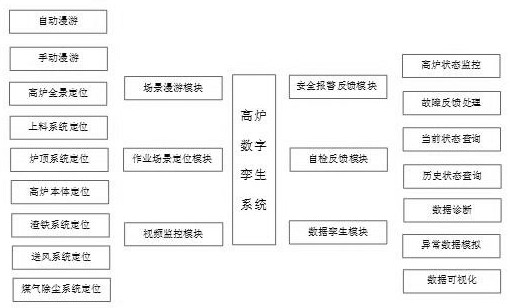

[0043] See figure 1 The present invention is a unity3D blast furnace digital twin system, including a scenario, a job scene positioning module, a video surveillance module, a security alarm feedback module, a self-test feedback module, a data twins module, a data diagnostic module, and a data visualization module. ,in:

[0044] The field view of the scene: for the user to control the viewpoint, the keyboard to the viewpoint, the viewpoint, and roam in the three-dimensional scene;

[0045]The work scene positioning module: The input and output of the scene is implemented by the selector, the selector is also responsible for classifying the scene, classify each of the different scenes, then follow Different separate loads;

[0046] The video surveillance module: Used for security technology prevention system construction, through remote control ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com