Long-acting circulating sodium carbon fluoride secondary battery and preparation method thereof

A sodium fluoride carbon, secondary battery technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of poor cycle performance of liquid electrolyte, improve cycle stability, simplify the preparation method, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

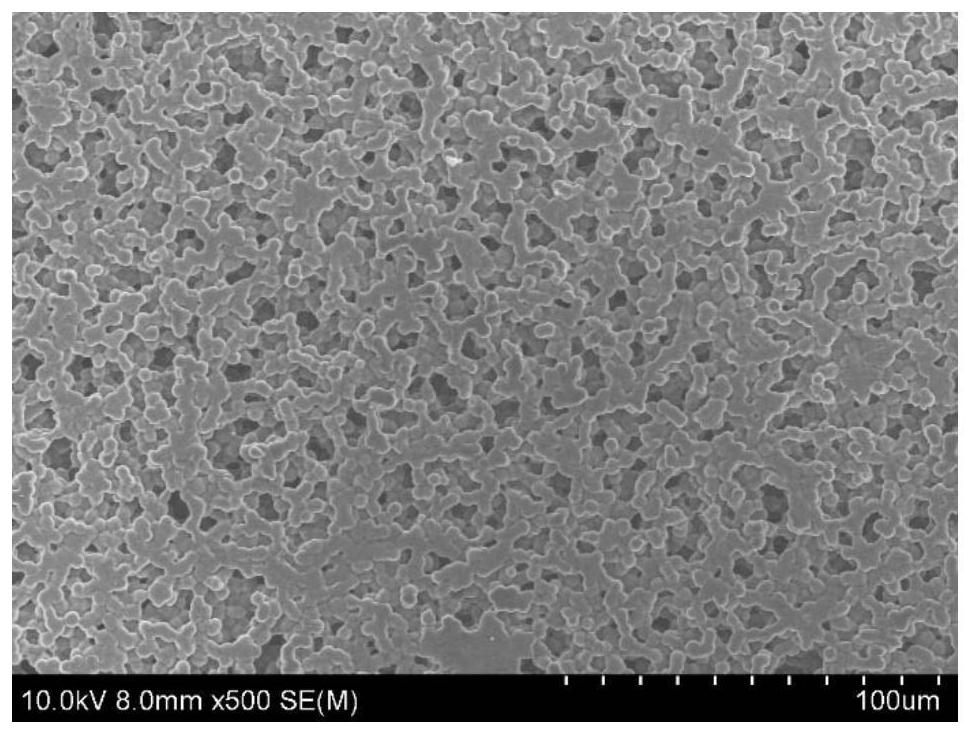

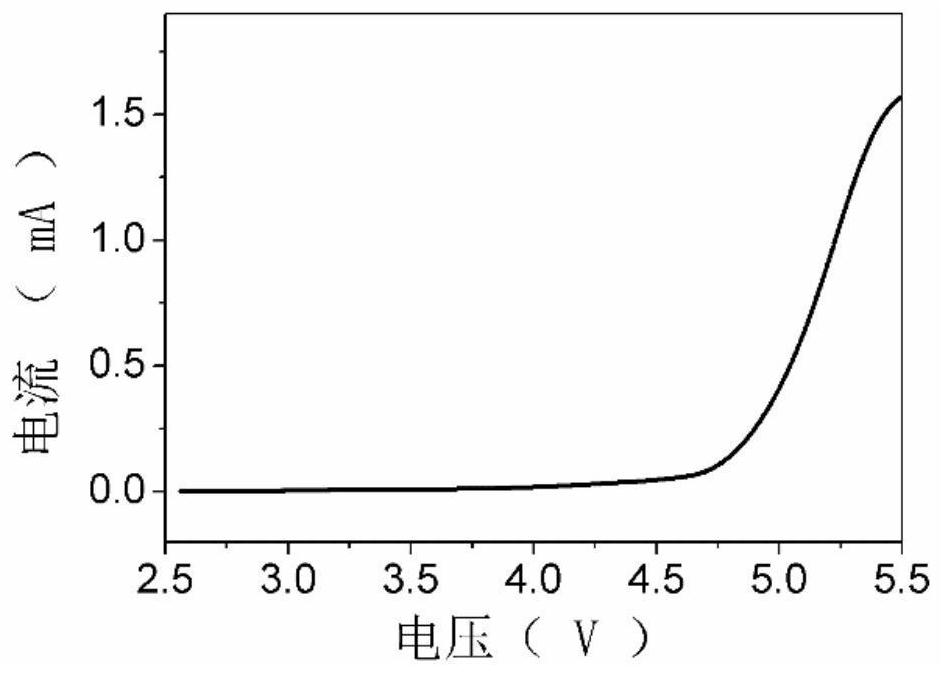

[0039] Preparation of sodium ion solid electrolyte: Dissolve 0.3g of polyvinylidene fluoride in 15mL of dimethylformamide. After the polyvinylidene fluoride is completely dissolved, add 0.1g NaTFSI, stir thoroughly for 4 hours, add 0.09g alumina, and stir overnight. The casting method is adopted to form a film, and the specific implementation method is: the above solution is poured into a mold, and the film is formed by vacuum heating at 60° C., and the vacuum degree is -0.1 MPa. Microscopic appearance such as figure 1 shown. The voltage stability test results are as follows figure 2 As shown, when the voltage is lower than 4.7V, the electrolyte is in a stable state. Therefore, when the positive electrode voltage is lower than 4.7V, the sodium ion solid electrolyte prepared by the present invention is suitable for a sodium fluoride secondary system and has good electrochemical stability.

[0040] Preparation of positive electrode sheet: take 5mg of graphene oxide, dispers...

Embodiment 2

[0044] Preparation of sodium ion solid electrolyte: Dissolve 0.3g of polyvinylidene fluoride in 15mL of dimethylformamide. After the polyvinylidene fluoride is completely dissolved, add 0.1g NaTFSI, stir well for 4 hours, then add 0.09g NaTFSI 3 Zr 2 Si 2 PO 12 , stirred overnight. The casting method is adopted to form a film, and the specific implementation method is: the above solution is poured into a mold, and the film is formed by vacuum heating at 60° C., and the vacuum degree is -0.1 MPa. Microscopic appearance such as Figure 5 shown.

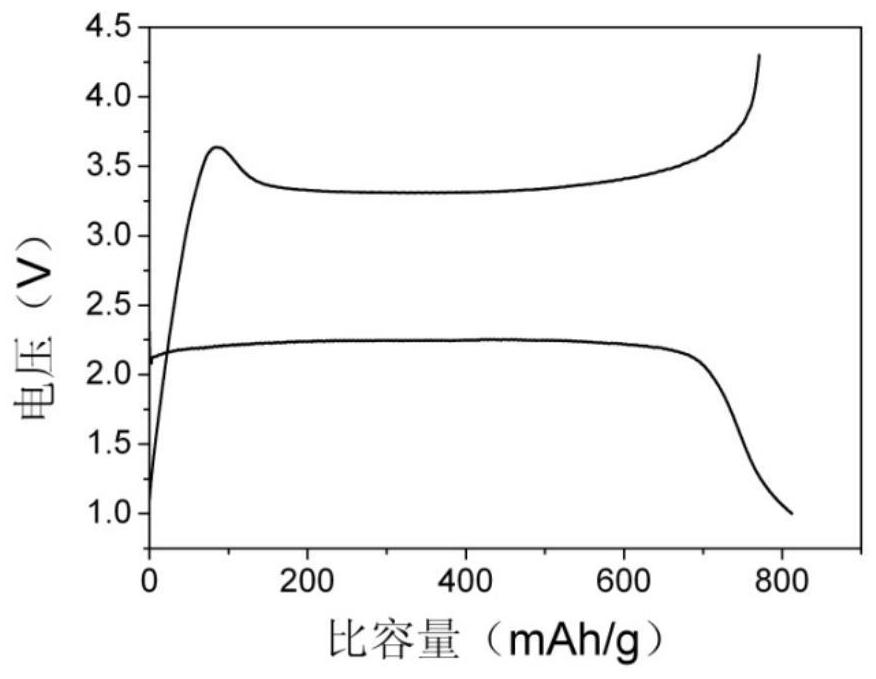

[0045] Preparation of the positive electrode sheet: 100 mg of polyvinylidene fluoride was dissolved in 3 ml of N-methylpyrrolidone (NMP), and stirred to form a uniform solution. Add 800 mg of carbon fluoride mesocarbon microspheres and 100 mg of superconducting carbon black conductive agent into the solution, and stir for 8 hours to prepare a carbon fluoride cathode active material slurry. The fluorinated carbon cathode active ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com