Frequency converter all-in-one machine and working method thereof

A frequency converter and all-in-one machine technology, applied in the field of frequency converters, can solve problems such as poor heat dissipation efficiency, and achieve the effects of facilitating centralized layout, improving service life, and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

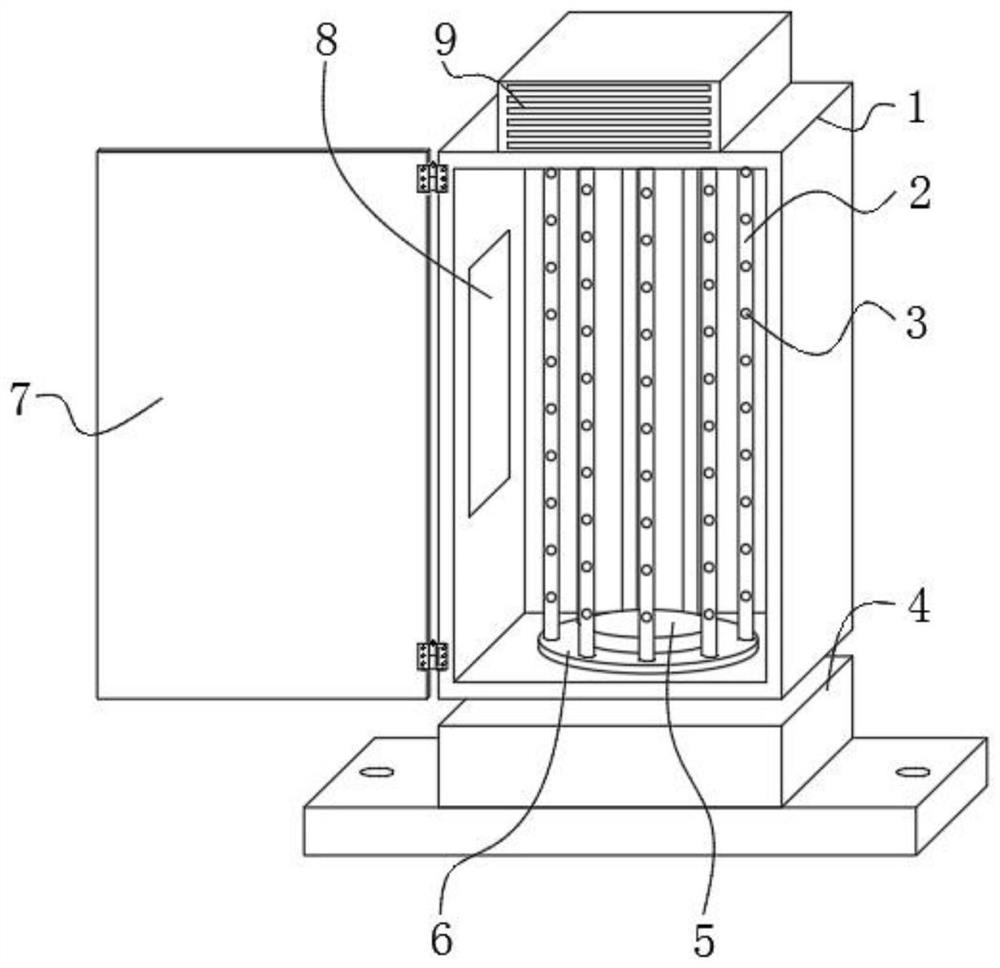

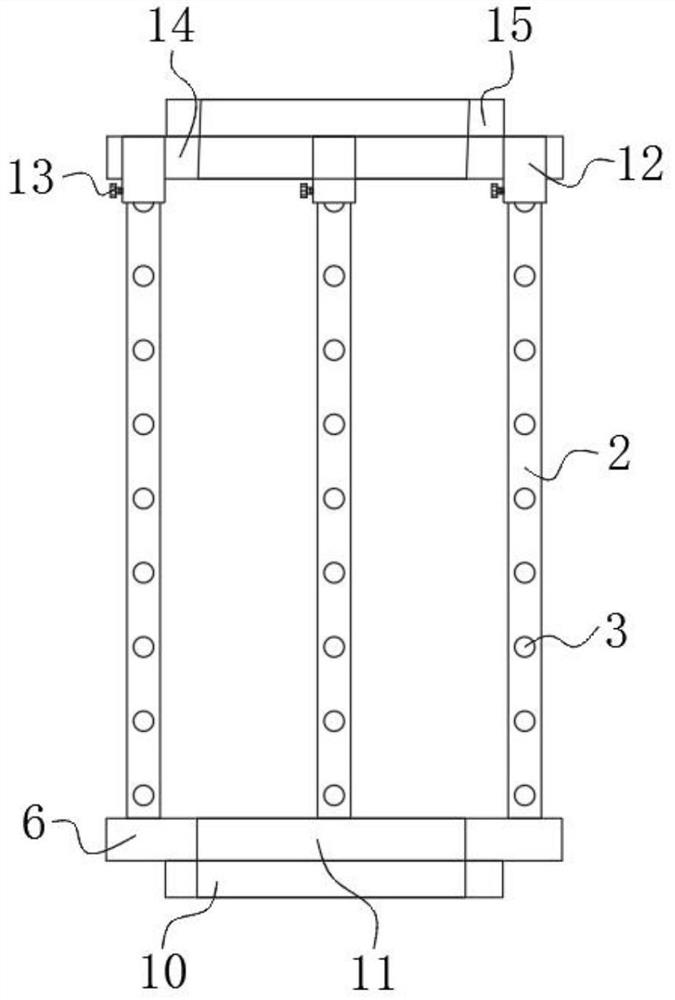

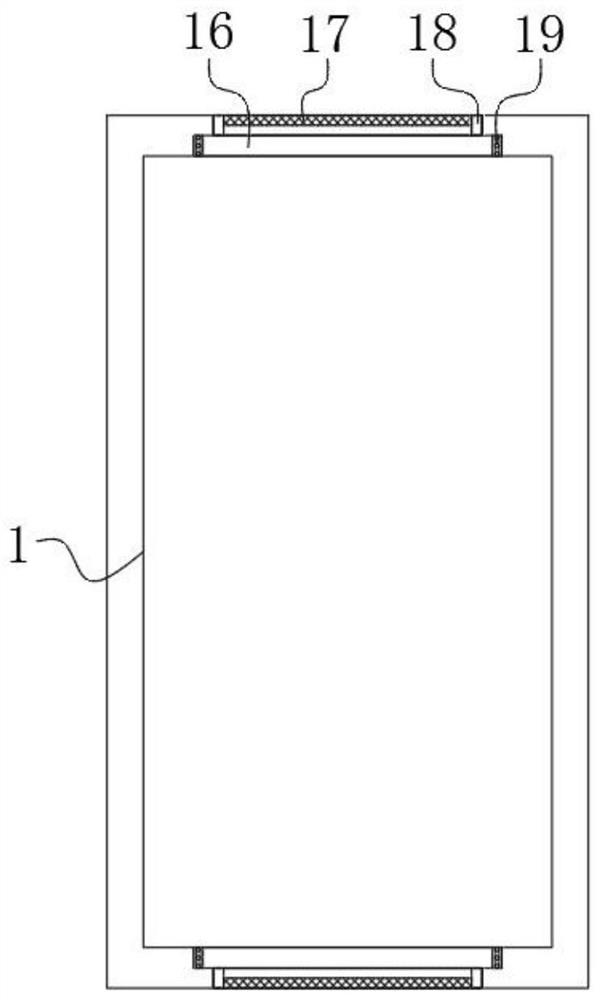

[0027] Attached below Figure 1-5 The specific implementation manner of the present invention will be described in further detail.

[0028] Depend on Figure 1-5 Given, the present invention provides the following technical solutions: a frequency converter integrated machine, including a frequency conversion box 1, a waterproof component 4 is installed on the bottom of the frequency conversion box 1, a door 7 is fixed on one side of the frequency conversion box 1 through a hinge, and the frequency conversion box 1 Vent hole 16 is provided at the top and bottom center of the inverter box 1, and the inside of the vent hole 16 at the bottom of the frequency conversion box 1 is connected to the lower deck 10 through bearing 19. The lower deck 10 is fixed at the bottom center of the lower turntable 6, and the lower turntable 6 There are equipment positioning rods 2 fixed around the top of the device, and several positioning holes 3 are provided on the equipment positioning rod 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com