Induction heating device

An induction heating device and sensor technology, applied in the direction of tobacco, etc., can solve the difficulty in controlling the consistency of the solder joint size, the consistency of the solder joint pulling force, and the difficulty in controlling the consistency of the heating effect of the wound coil, which affects the popularization and use of heating appliances. and other problems, to achieve the effect of accurate and convenient temperature detection, high electromagnetic conversion efficiency and saving structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

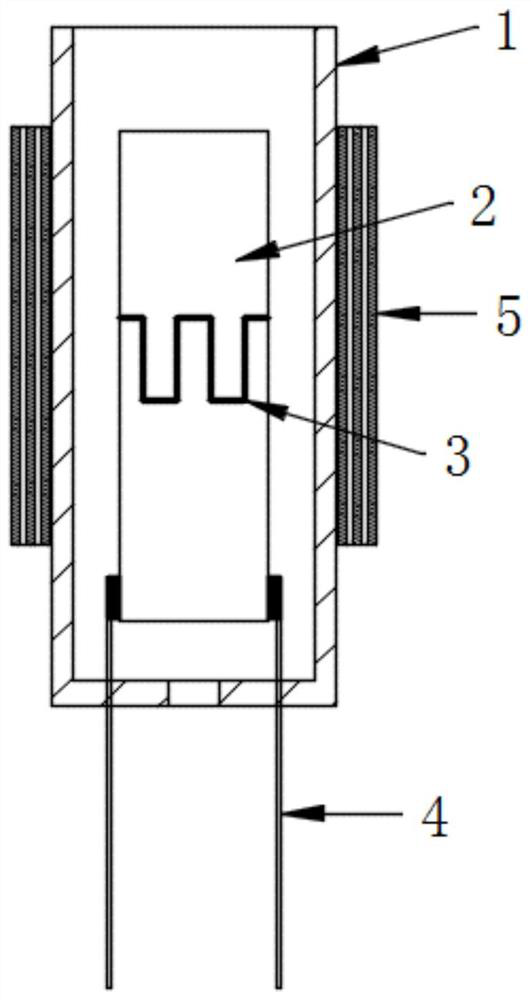

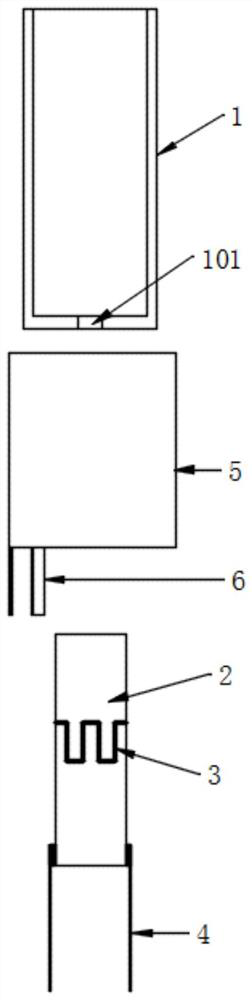

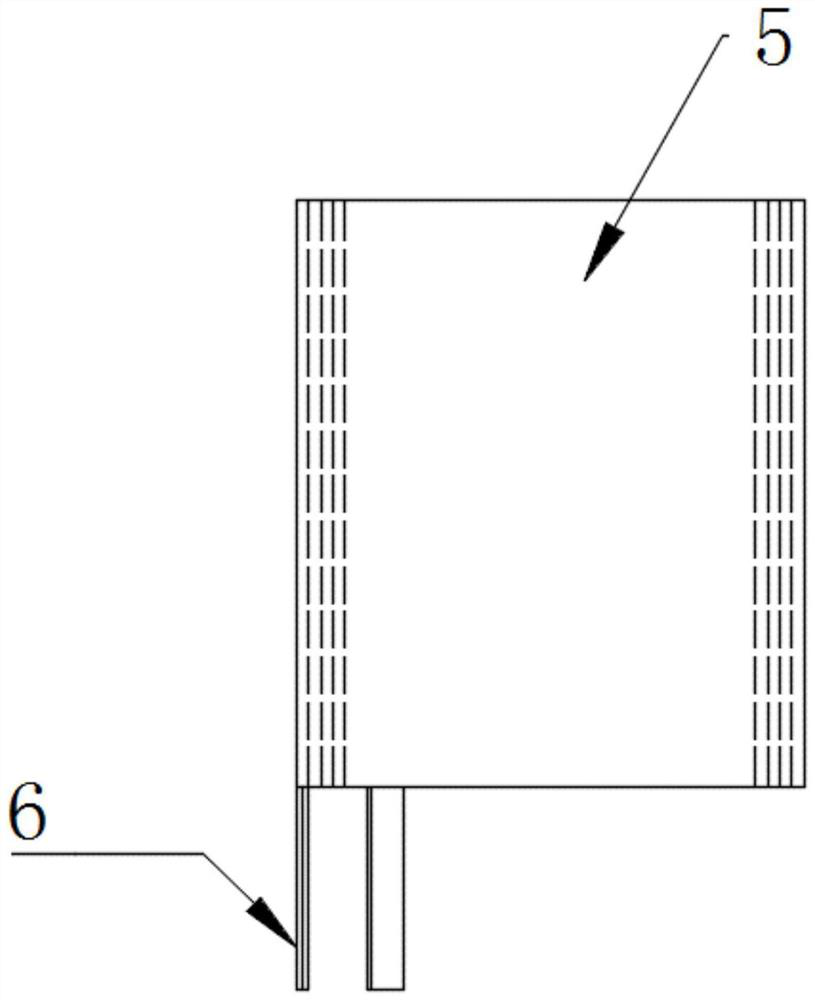

[0037] In order to solve the problems of low energy conversion efficiency of the induction coil of the induction heating device in the prior art, difficulty in winding the coil, and poor consistency of the heating effect after winding; It is difficult to control the size consistency of the solder joints and the consistency of the pull-out force of the solder joints during touch welding, and the welding wire on the middle surface of the heating body brings difficulties to the sealing of the entire heating module, which affects the consistency and cost of the device. The present invention aims to provide an induction heating device, the core idea of which is: an inductor is formed by wrapping a metal sheet around the outer surface of an insulating tube several times. Compared with ordinary coils, the inductor has a simpler winding process and is easy to control Consistency of the heating effect, its effective cross-section is larger, so the electromagnetic conversion efficiency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com