Processor and processing method for agricultural chemical fertilizer hardened with damp

A technology for agricultural chemical fertilizers and processing machines, applied in chemical instruments and methods, grain processing, dryers, etc., can solve the problems of low yield, many steps, and insufficient fertilizer crushing and processing, so as to reduce power supply and energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

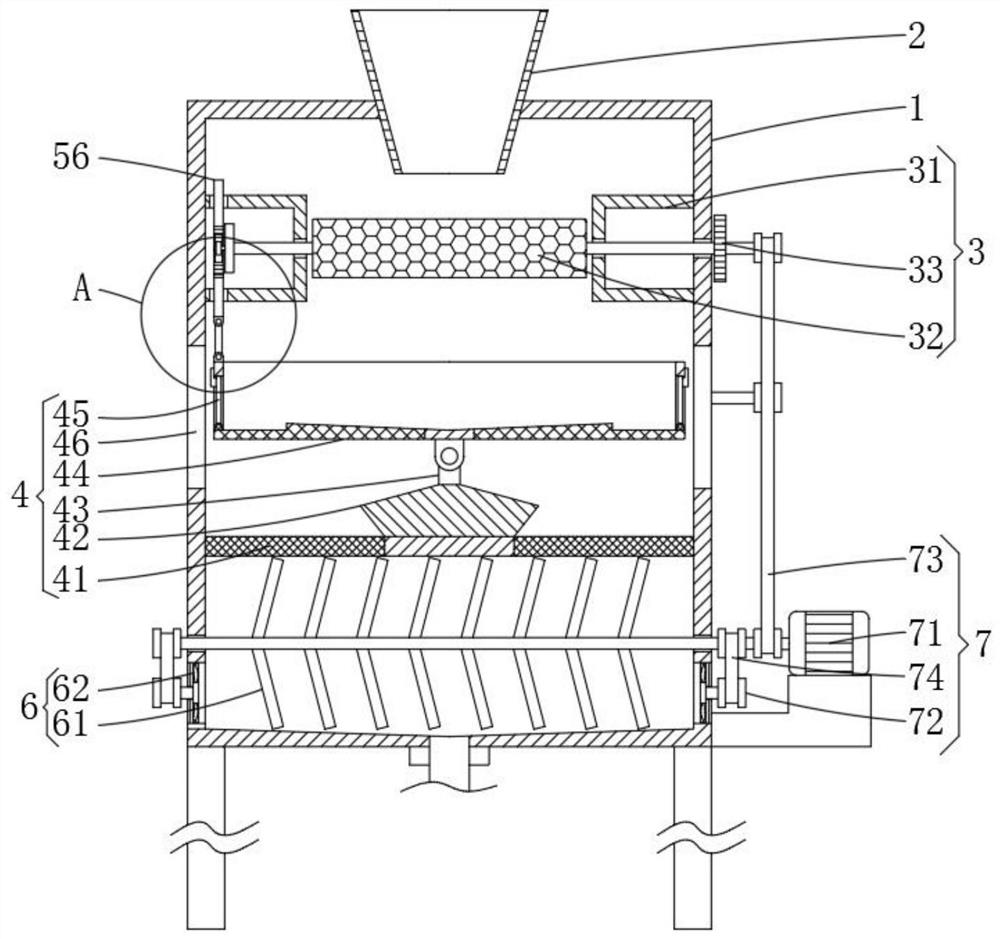

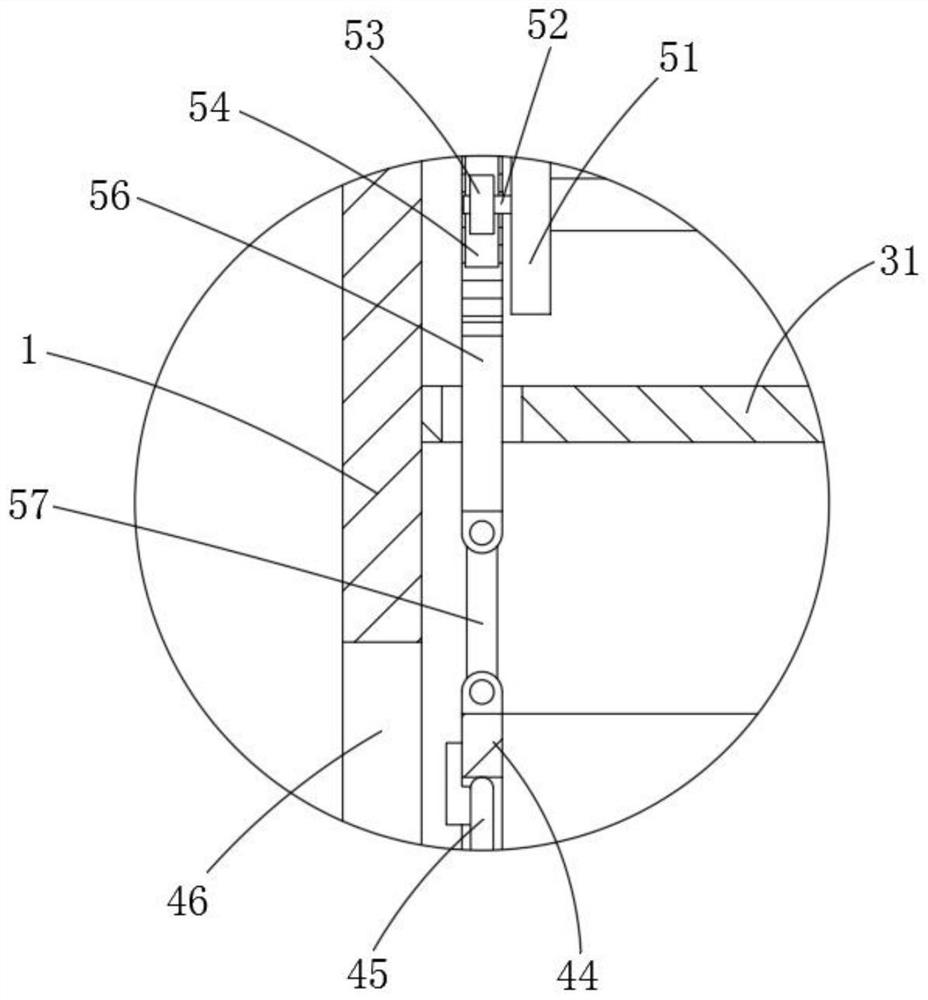

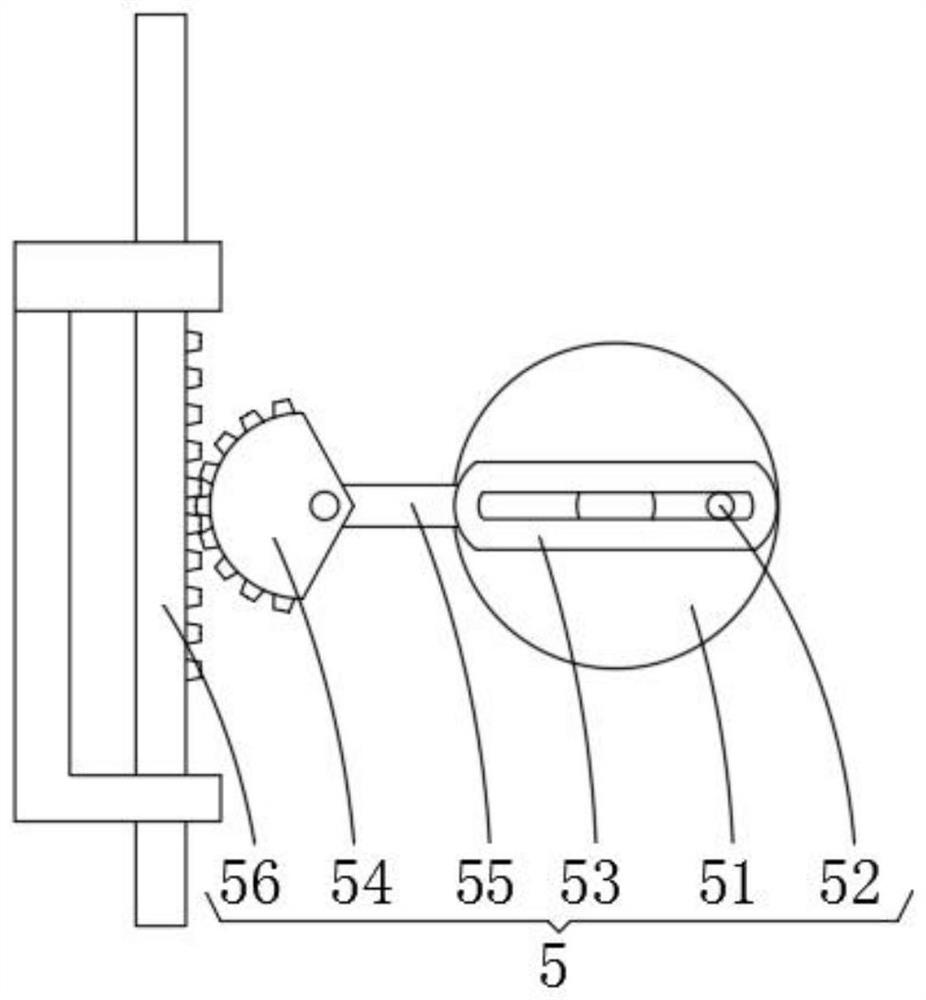

[0042] see Figure 1-4 , a processing machine for agricultural chemical fertilizers affected by moisture, comprising a box body 1, the top of the box body 1 is pierced with a feed hopper 2, the box body 1 is located below the feed hopper 2 and a crushing assembly 3 is arranged, and the box body 1 is located at the crushing A screening assembly 4 is provided below the assembly 3, and the screening assembly 4 is connected to the screening assembly 4 through a transmission assembly 5. The box body 1 is located below the screening assembly 4 and is provided with a dehumidification assembly 6, and the dehumidification assembly 6 and the crushing assembly 3 pass through Drive assembly 7 transmission connection;

[0043] Specifically, the box body 1 is used for processing the wet-hardened agricultural chemical fertilizer, and the damp-hardened agricultural chemical fertilizer enters the inside of the box body 1 through the feed hopper 2, and the wet-hardened agricultural chemical fer...

Embodiment 2

[0055] see Figure 5 and Figure 6 , the interior of the feed hopper 2 is provided with a crushing assembly 8, the crushing assembly 8 includes two crushing plates 81 distributed symmetrically, two sliding blocks 82 are slidably connected to the side wall of the feeding hopper 2, and the sliding block 82 and the crushing plate 81 A guide plate 83 is hinged between them, and the crushing plate 81 is slidingly connected with the side wall of the feed hopper 2 through a moving rod 84. The end of the moving rod 84 is provided with a roller 85, and one side of the feed hopper 2 is fixedly connected with a mounting block 86. , the moving rod 84 is fixedly connected with a spring 87 between the mounting block 86 and the roller 85, and the roller 85 is provided with a cam 88 suitable for the roller 85, and the bottom end of the cam 88 is fixedly connected with the shaft of the crushing roller 32 There is a bevel gear 89, and two bevel gears 89 are meshed;

[0056] Specifically, when...

Embodiment 3

[0058] see Figure 7 and Figure 8 A scraper assembly 9 is also provided below the feed hopper 2. The scraper assembly 9 includes a baffle plate 91 located on the outside of the two pulverizing rollers 32, and a plurality of evenly distributed scraping bars are arranged inside the baffle plate 91. 92, the tops of the two baffle plates 91 are fixedly connected by a U-shaped frame 93, and the U-shaped frame 93 is fixedly connected with the top of the sliding rod 56;

[0059] Concrete, because the agricultural chemical fertilizer that feeds in the feeding hopper 2 has certain wetness, pulverizing through crushing roller 32 can make residual part of agricultural chemical fertilizer on the crushing roller 32, the setting of material blocking plate 91, to feed hopper 2 The internal raw materials are guided again, so that the agricultural chemical fertilizer can be crushed from the center of the two crushing rollers 32. The scraper 92 is set to scrape the outer surface of the crushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com