Sucker rod high-pressure jet flow mechanical rotary brush composite scale removing device and method

A high-pressure jet and sucker rod technology is applied in the fields of oil field cleaning, high-pressure jet, fracture mechanics, and hydraulic motors. It can solve the problems of shortening the pump inspection cycle, heavy workload, and high cost, and achieves reduced complex work, strong in-depth capabilities, and The effect of high torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

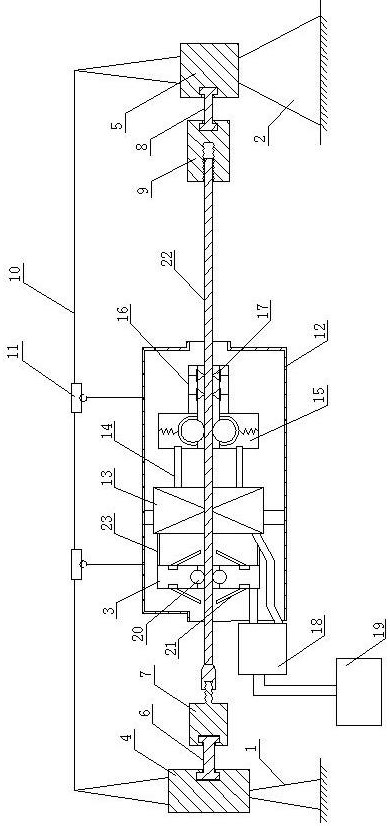

[0020] A high-pressure jet mechanical rotary brush composite descaling device for sucker rods of the present invention includes a front support frame 1, a rear support frame 2 and a cleaning nozzle 3, and the front support frame 1 is equipped with a front fixing frame 4 and a rear support frame 2 The rear fixing frame 5 is installed on the top, and the inner side of the front fixing frame 4 is flexibly connected with the fixed and tensioned male joint 7 of the rod end through the front tightening connection short rod 6, and the inner side of the rear fixing frame 5 is fixed with the rod end through the rear tightening connection short rod 8 Tighten the flexible connection of the female joint 9, the upper part between the front fixed frame 4 and the rear fixed frame 5 is fixed with a slideway beam 10, the slideway beam 10 is equipped with a slider 11, and a circular protective sleeve 12 is hoisted below the slider 11, A hydraulic motor 13 is fixedly installed in the circular pro...

Embodiment 2

[0022] A sucker rod high-pressure jet mechanical rotary brush composite descaling device of the present invention includes a front support frame 1, a rear support frame 2 and a cleaning nozzle 3, and the front support frame 1 is equipped with a front fixing frame 4 and a rear support frame 2. The rear fixed frame 5 is installed, and the inner side of the front fixed frame 4 is flexibly connected with the fixed and tensioned male joint 7 of the rod end through the front tension connection short rod 6, and the rear fixed frame 5 is connected with the fixed tension rod 8 and the rod end by the rear tensioned connection short rod 8. The tight female joint 9 is movably connected, and the upper part between the front fixed frame 4 and the rear fixed frame 5 is fixed with a slideway crossbeam 10, the slideway crossbeam 10 is equipped with a slide block 11, and a circular protective sleeve 12 is hoisted below the slide block 11. The hydraulic motor 13 is fixedly installed in the protec...

Embodiment 3

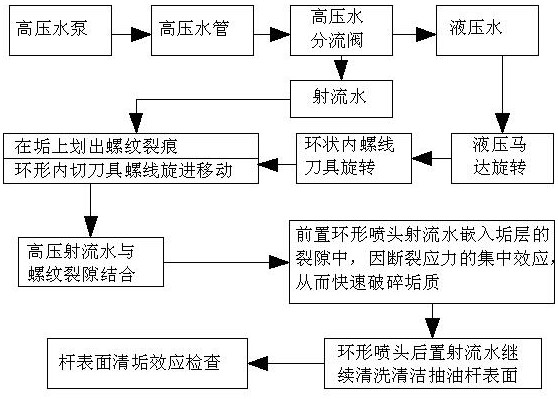

[0025] A kind of sucker rod high-pressure jet mechanical rotary brush composite descaling method of the present invention, through the following steps:

[0026] a. Pass the sucker rod to be cleaned through the cleaning nozzle and the center hole of the hydraulic motor, and fix both ends on the rod end fixed tension male joint and the rod end fixed tension female joint;

[0027] b. Start the high-pressure water pump, the high-pressure water flows into the diverter valve through the high-pressure water pipe, part of the high-speed fluid enters the cleaning nozzle, and the other part of the high-pressure fluid enters the hydraulic motor to make it rotate;

[0028] c. The hydraulic motor drives the internal thread cutter to rotate;

[0029] d. The rotating internal thread cutter scratches the surface of the hard scale; the screw thread advance force drags the motor system to move forward;

[0030] e. The nozzle of the high-pressure nozzle ejects high-pressure jet water at high sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com