Intelligent automobile loading station system and method

A technology for loading stations and cars, which is applied in the field of intelligent car loading station system, which can solve the problems of multiple personnel, low efficiency, errors, etc., and achieve the effects of optimizing the loading process, reducing construction costs, and reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

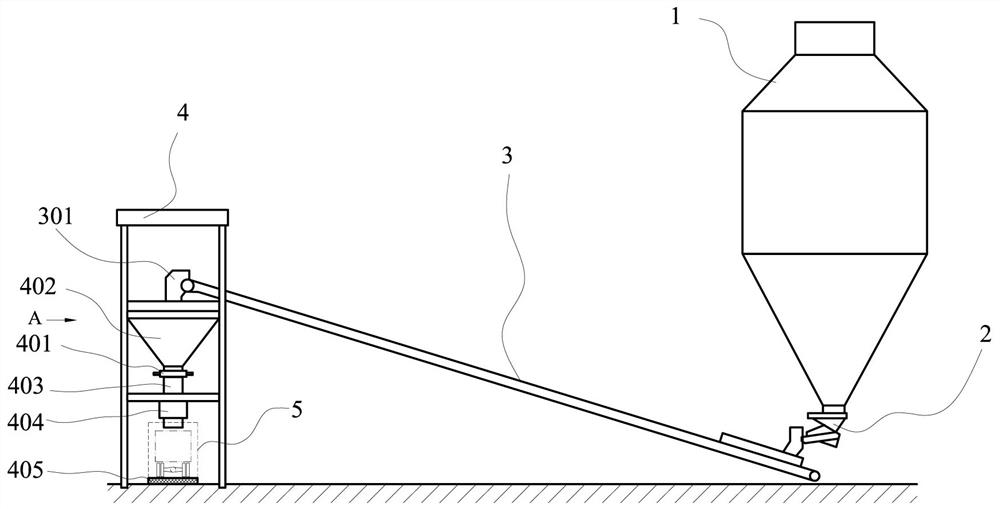

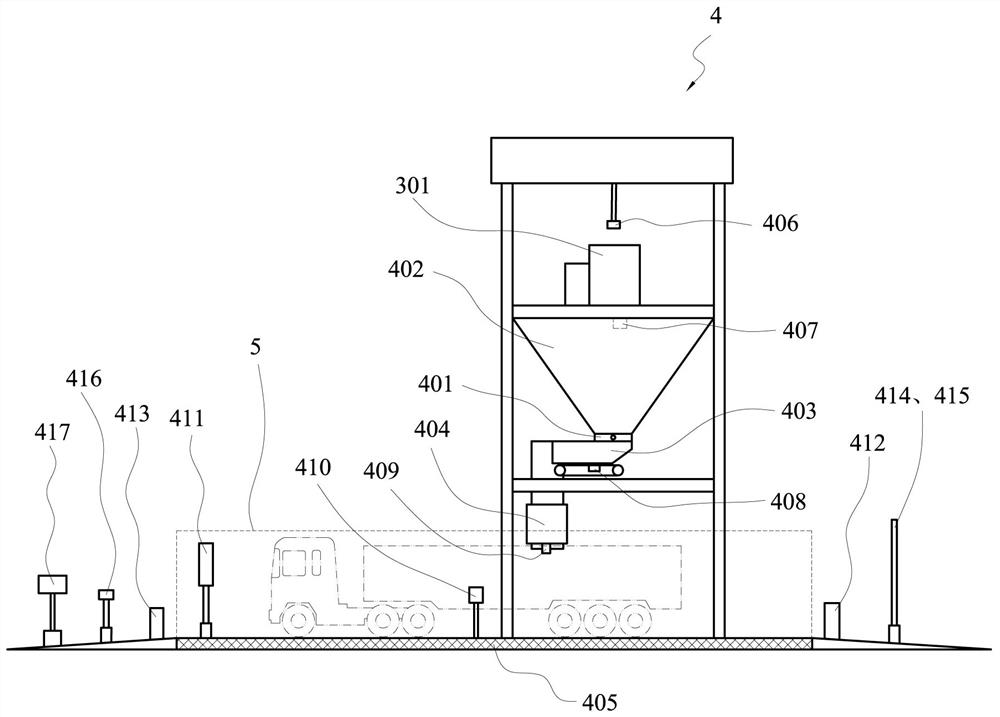

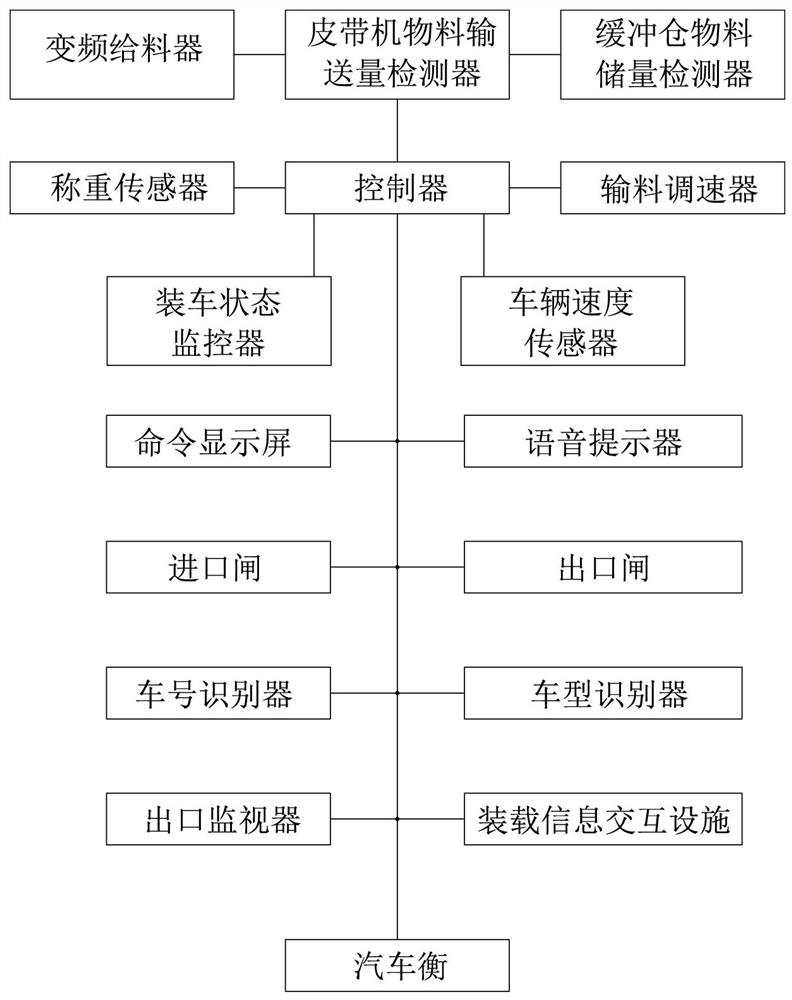

[0028] The present embodiment is a kind of intelligent automobile loading station system, such as figure 1 , 2 , 3 shown. This embodiment includes: a storage bin 1, the bottom of the storage bin is provided with a frequency conversion feeder 2, and the frequency conversion feeder is connected with the belt conveyor 3, and the head 301 of the belt conveyor is arranged on the At the top of the car machine 4, the car loading machine is sequentially provided with a buffer bin 402, a distributor 403, and a lifting chute 404 connected with the belt head with a buffer bin gate 401 from top to bottom; The loading space 5 is provided with a truck scale 405, and the belt conveyor and the buffer bin are respectively provided with a belt conveyor material delivery detector 406 and a buffer bin material storage detector 407, and the distributor is provided with a load cell 408 and a load cell 408. Conveyor speed controller, above the loading space is provided with a loading state monitor...

Embodiment 2

[0058] This embodiment is an improvement of the first embodiment, and is a refinement of the first embodiment regarding the parking space. The front of the loading space described in the present embodiment is provided with command display screen 411 and voice prompter, and described command display screen and voice prompter are connected with controller signal, as figure 2 , 3 shown.

[0059] The command display can adopt large-screen LED dot matrix display or LED color display. The dot-matrix display can only display numbers and letters, while the color display can display animation. The real-time status between the vehicle and the chute when the vehicle is about to be loaded is displayed in animation, so that the truck driver can better control his vehicle.

[0060] The voice prompter can be a special audio device, or it can be a built-in audio device of the LED color display.

Embodiment 3

[0062] This embodiment is an improvement of the above embodiment, and is a refinement of the above embodiment regarding the parking space. The entrance of the loading space described in this embodiment is provided with an entrance gate 412, and the exit of the loading space is provided with an exit gate 413, and the described entrance gate and exit gate are connected with the controller signal, such as figure 2 , 3 shown.

[0063] The entrance gate and exit gate can adopt the lifting pole gate of the general parking lot. Its function is to control the vehicle entering and exiting the loading station. When the driver can clearly know when to enter and when to drive out, it is also convenient for the system to clarify the various aspects of vehicle operation. point in time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com