Method for preparing aromatic polyester polyol with good pentane compatibility

An aromatic polyester and polyol technology, applied in the field of foaming agents, can solve problems such as poor compatibility of premixed pentane and aromatic polyester polyol, and achieve low cost, convenient operation, and easy mass production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

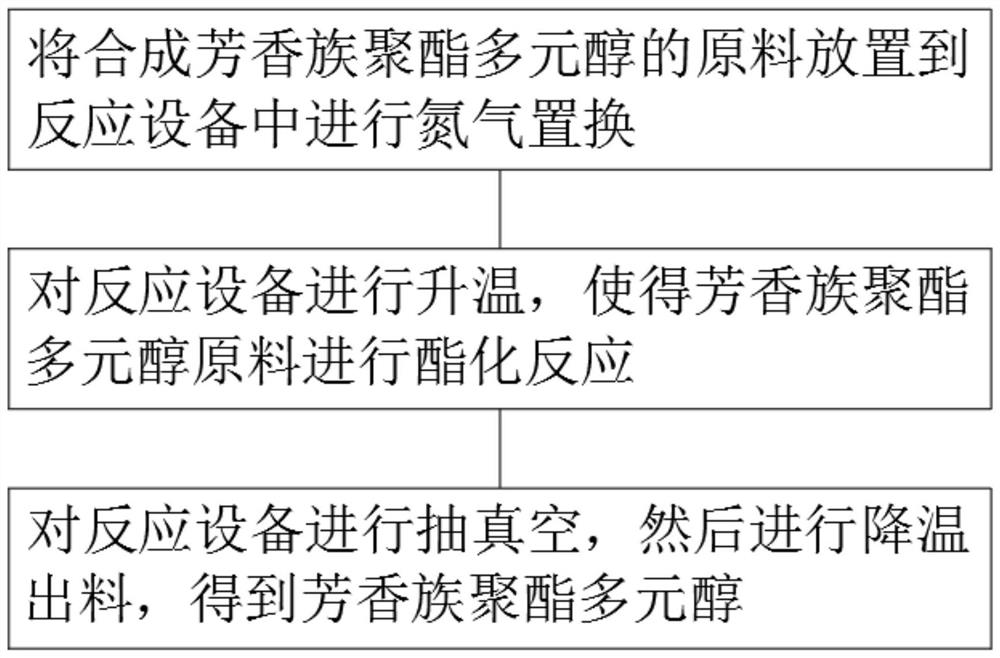

Method used

Image

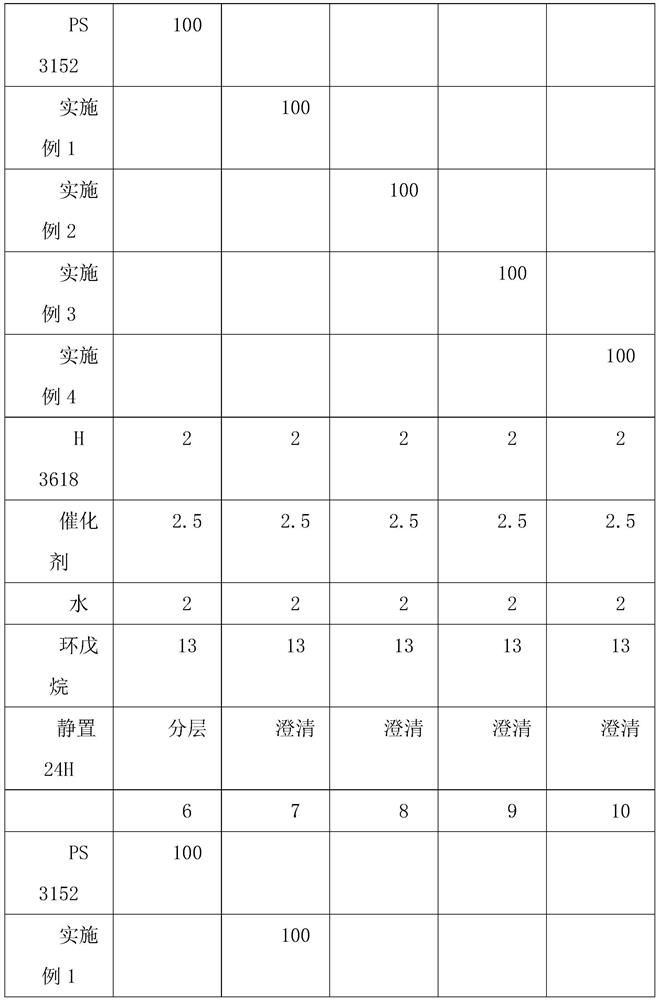

Examples

Embodiment 1

[0019] Connect a water separator, agitator, condenser, thermometer and an electric heater to a 1.5L 4-necked flask, add 70g glycerin, 450g dipropylene glycol, 150g stearic acid, 350g phthalic anhydride and 0.2g T9, and heat up to 150°C after nitrogen replacement Carry out esterification reaction, cool down to 130 DEG C after 5 hours and vacuumize for 3 hours, cool down and discharge, and obtain a brown-yellow transparent product. The brown-yellow transparent product is tested, and the hydroxyl value test result is 220 mgKOH / g, and the viscosity is 9000 cps (25 DEG C).

Embodiment 2

[0021] Connect a water separator, stirrer, condenser, thermometer and electric heater to a 1.5L 4-necked flask, add 70g glycerin, 450g dipropylene glycol, 100g palmitic acid, 350g phthalic anhydride and 0.2g T9, and heat up to 150°C after nitrogen replacement Carry out esterification reaction, after 5 hours, cool down to 130°C and apply vacuum for 3 hours, then cool down and discharge to obtain a brownish-yellow transparent product with a hydroxyl value test result of 250mgKOH / g and a viscosity of 12000cps (25°C).

Embodiment 3

[0023] Connect a water separator, agitator, condenser, thermometer and an electric heater to a 1.5L 4-necked flask, add 70g glycerin, 400g dipropylene glycol, 200g oleic acid, 350g phthalic anhydride and 0.2g T9, and heat up to 150°C after nitrogen replacement After 5 hours of esterification reaction, the temperature was lowered to 130°C for 3 hours, the temperature was lowered and the material was discharged to obtain a brownish-yellow transparent product with a hydroxyl value test result of 170mgKOH / g and a viscosity of 13000cps (25°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com