A method of manufacturing a protective insulating material capable of automatically repairing electronic circuits

A technology for electronic circuits and insulating materials, applied in circuits, insulators, insulators, etc., can solve problems such as no repair method and cumbersome detection process, and achieve the effect of improving operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

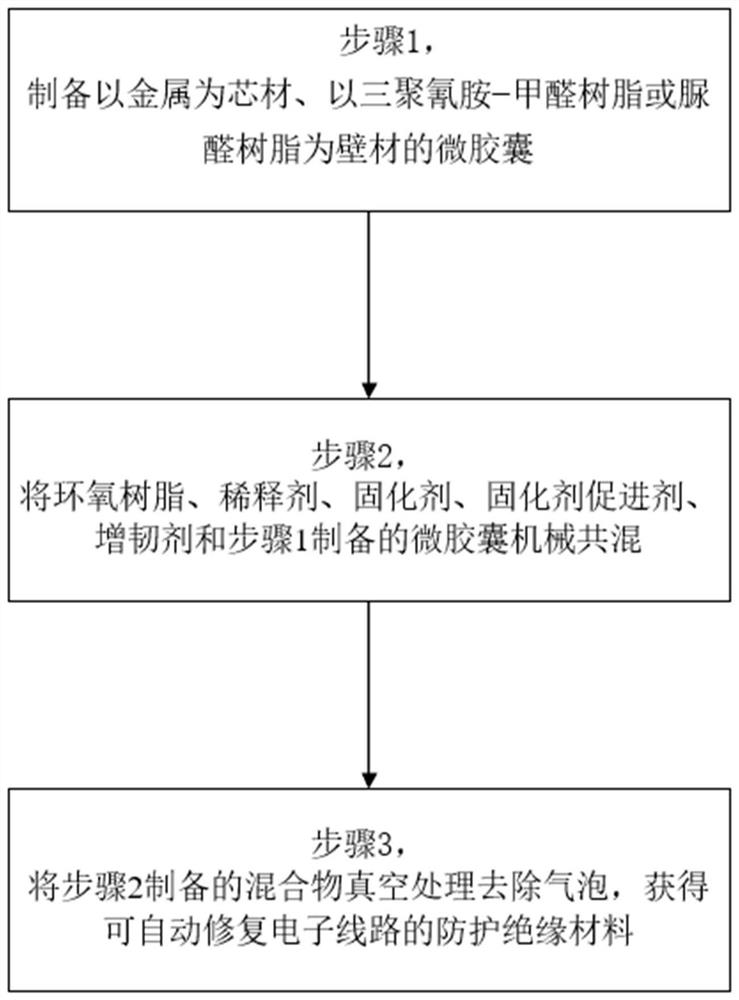

[0035] Preferred embodiment 1 of the present invention provides a kind of manufacturing method that can automatically repair the protective insulating material of electronic circuit, comprises the following steps:

[0036] Step 1, preparing microcapsules with metallic gallium as the core material and urea-formaldehyde resin as the wall material. Specifically include:

[0037] Step 1.1, react 1.0 parts of AR grade urea, 2.2 parts of 37% formaldehyde and deionized water under alkaline, heating and stirring conditions to generate a urea-formaldehyde resin prepolymer solution; wherein, the alkaline condition is pH=8.5, heating The condition is electric heating at 73°C, the stirring condition is 350rpm magnetic stirring, and the reaction time is 1.25h.

[0038] Step 1.2, with 4.5 parts of AR grade sodium dodecylbenzene sulfonate as emulsifier, 90 parts of AR grade metal gallium as metal core material and deionized water to generate core material emulsion under heating and stirring...

Embodiment 2

[0045]Preferred embodiment 2 of the present invention provides another method for manufacturing a protective insulating material capable of automatically repairing electronic circuits, comprising the following steps:

[0046] Step 1, preparing microcapsules with metallic gallium as the core material and urea-formaldehyde resin as the wall material. Specifically include:

[0047] Step 1.1, react 0.9 parts of urea of AR grade, 2.0 parts of formaldehyde of 35% concentration and deionized water under alkaline, heating and stirring conditions to generate a urea-formaldehyde resin prepolymer solution; wherein, the alkaline condition is pH=8.0, The heating condition is electric heating at 70° C., the stirring condition is 300 rpm magnetic stirring, and the reaction time is 1 h.

[0048] Step 1.2, use 4 parts of AR grade sodium dodecylbenzene sulfonate as emulsifier, 80 parts of AR grade metal gallium as metal core material and deionized water to generate core material emulsion und...

Embodiment 3

[0054] Preferred embodiment 3 of the present invention provides yet another method for manufacturing a protective insulating material capable of automatically repairing electronic circuits, comprising the following steps:

[0055] Step 1, preparing microcapsules with metallic gallium as the core material and urea-formaldehyde resin as the wall material. Specifically include:

[0056] Step 1.1, react 1.1 parts of urea of AR grade, 2.4 parts of formaldehyde of 40% concentration and deionized water under alkaline, heating and stirring conditions to generate a urea-formaldehyde resin prepolymer solution; wherein, the alkaline condition is pH=9.0, The heating condition is electric heating at 75° C., the stirring condition is 400 rpm magnetic stirring, and the reaction time is 1.5 h.

[0057] Step 1.2, use 5 parts of AR grade sodium dodecylbenzene sulfonate as emulsifier, 100 parts of AR grade metal gallium as metal core material and deionized water to generate core material emul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com