A kind of anti-corrosion coating that can be repaired automatically in acidic environment and its preparation method

An automatic repair and anti-corrosion coating technology, which is applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of easy damage to the integrity of the coating, poor coating compatibility, large amount of nanoparticles, etc., to achieve a solution Compatibility issues, enhanced compatibility, corrosion inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

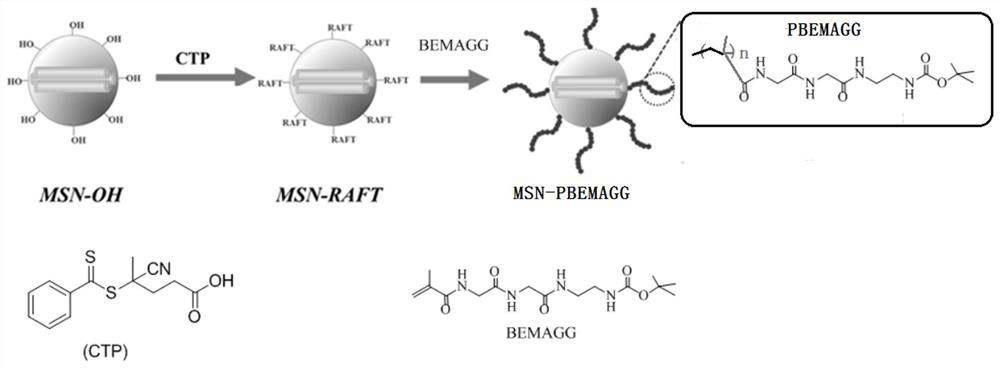

[0053] Schematic diagram of the preparation of acid-responsive mesoporous silica and the chemical structures of the main reagents such as figure 1 shown.

[0054] A self-healing anti-corrosion coating in an acidic environment, comprising the following parts

[0055] (1) Acid-responsive mesoporous silica loaded with corrosion inhibitor 0.5-5 parts by weight

[0056] (2) Cured resin 95-99.5 parts by weight

[0057] The resin cured product is formed by curing epoxy resin, epoxy curing agent and water.

[0058] The epoxy resin is bisphenol A type epoxy resin, and the epoxy curing agent is polyetheramine D230 and n-decylamine.

[0059] The cured resin is a cured polyurethane formed by curing a hydroxyl-containing resin, an isocyanate curing agent and water.

[0060] The acid-responsive mesoporous silica loaded with a corrosion inhibitor is composed of a corrosion inhibitor and an acid-responsive mesoporous silica, the corrosion inhibitor is located in the pore structure of the ...

Embodiment 1

[0090] A preparation method for an anti-corrosion coating that can be automatically repaired in an acidic environment, comprising the following steps:

[0091] (1) Preparation of mesoporous silica as a nano container;

[0092] (1a): Dissolve 10g of dodecyltrimethylammonium bromide and 5g of sodium hydroxide in 5L of water to obtain an alkaline aqueous solution; slowly drop 50mL of tetraethyloxysilane into the above alkaline aqueous solution, and react at a constant temperature under stirring 4h, the reaction temperature was 70°C; centrifuged, washed and dried to obtain mesoporous silica microspheres MSN;

[0093](1b): Disperse mesoporous silica microspheres MSN in toluene solution, add silane coupling agent-glycidyl ether propyl trimethoxysilane drop by drop, reflux reaction for 12h, centrifuge, wash and dry to obtain ring Oxygen-modified mesoporous silica microspheres (MSN-epoxy);

[0094] The weight ratio of mesoporous silica microspheres to glycidyl ether propyl trimethox...

Embodiment 2

[0104] A preparation method for an anti-corrosion coating that can be automatically repaired in an acidic environment, comprising the following steps:

[0105] A method for preparing an automatically repairable anti-corrosion coating, comprising the following steps:

[0106] (1) Preparation of mesoporous silica as a nano container;

[0107] (1a): Dissolve 15g of dodecyltrimethylammonium bromide and 6g of sodium hydroxide in 5L of water to obtain an alkaline aqueous solution; slowly drop 100mL of tetraethyloxysilane into the above alkaline aqueous solution, and react at a constant temperature under stirring 4.5h, the reaction temperature is 75°C; centrifuge, wash and dry to obtain mesoporous silica microspheres MSN;

[0108] (1b): Disperse mesoporous silica microspheres MSN in toluene solution, add silane coupling agent-glycidyl ether propyl trimethoxysilane drop by drop, reflux reaction for 13h, centrifuge, wash and dry to obtain ring Oxygen-modified mesoporous silica micros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com