Hot-blast stove combustor rapid cleaning method and tool

A cleaning method and burner technology, applied in furnaces, blast furnaces, heating furnaces, etc., can solve the problems of difficult pouring of refractory materials, difficult to clean up completely, poor stability of effects, etc., and achieve the improvement of technical indicators and the time required for cleaning. Short, obvious effect of wind temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] It is worth noting that the orientation words such as "up" and "down" involved in this article are all determined relative to the perspective of the drawings, and are only for the convenience of description, and cannot be understood as limitations on the technical solution.

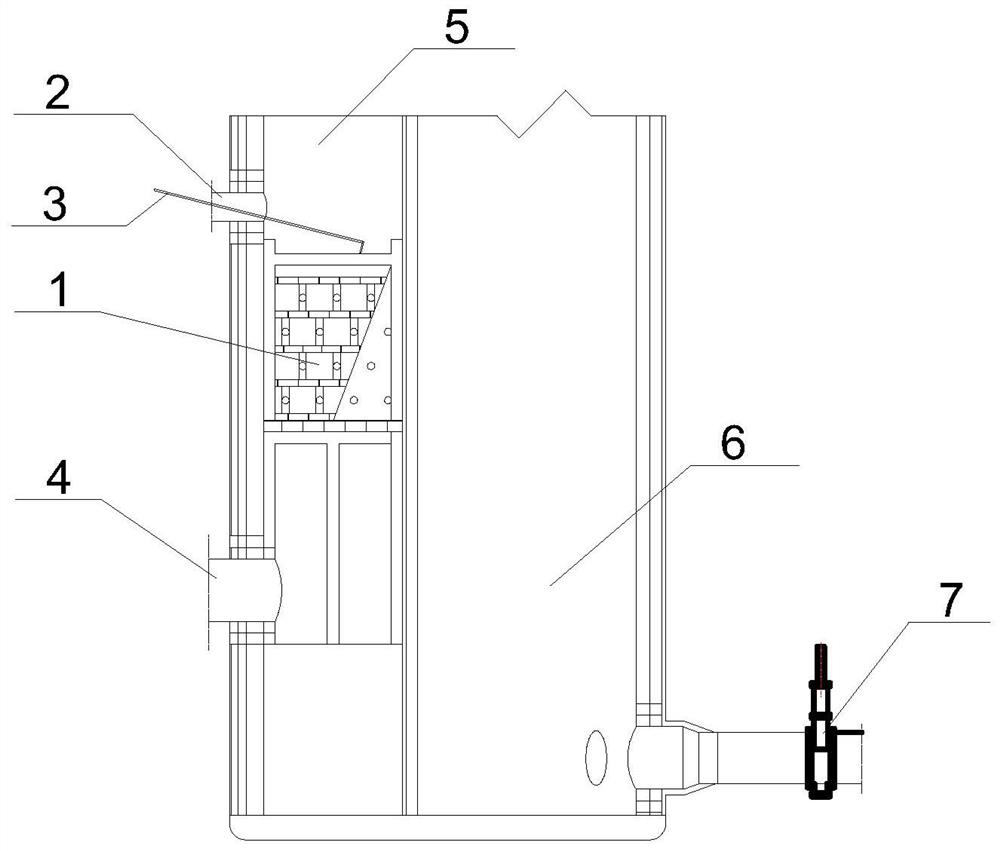

[0031] Such as Figure 1-5 As shown, a quick cleaning method and tool for a hot blast stove burner, comprising the following steps:

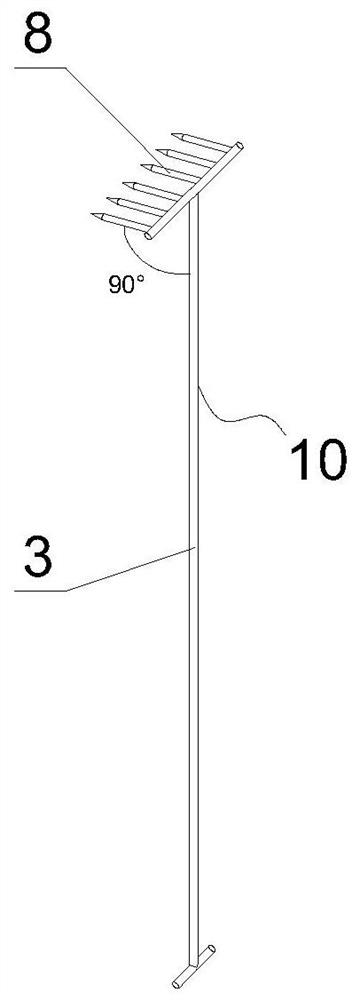

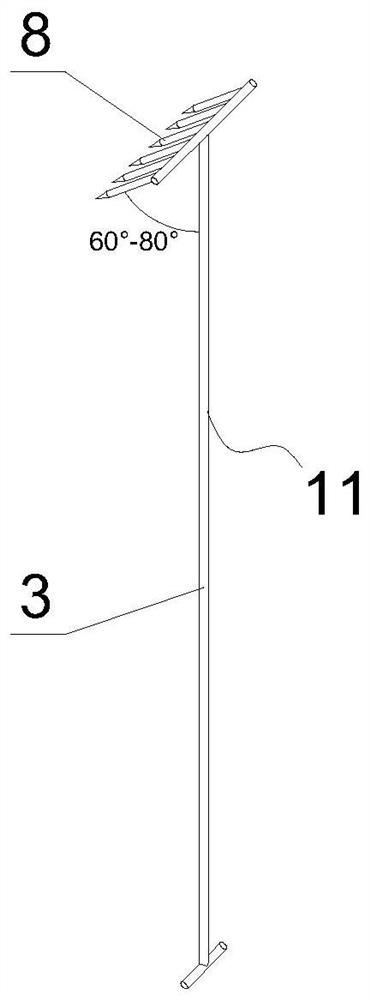

[0032] S1, make cleaning tool, cleaning tool comprises the first comb rake 10, the second comb rake 11 and the first plate rake 12, the second plate rake 13: the first comb rake 10 and the second comb rake 11 are all made of straight bar 3 and Composed of the first rake body 8, the first rake body 8 is comb-shaped, the difference is that the straight bar 3 of the first comb rake 10 is perpendicular to the first rake body 8, and the straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com