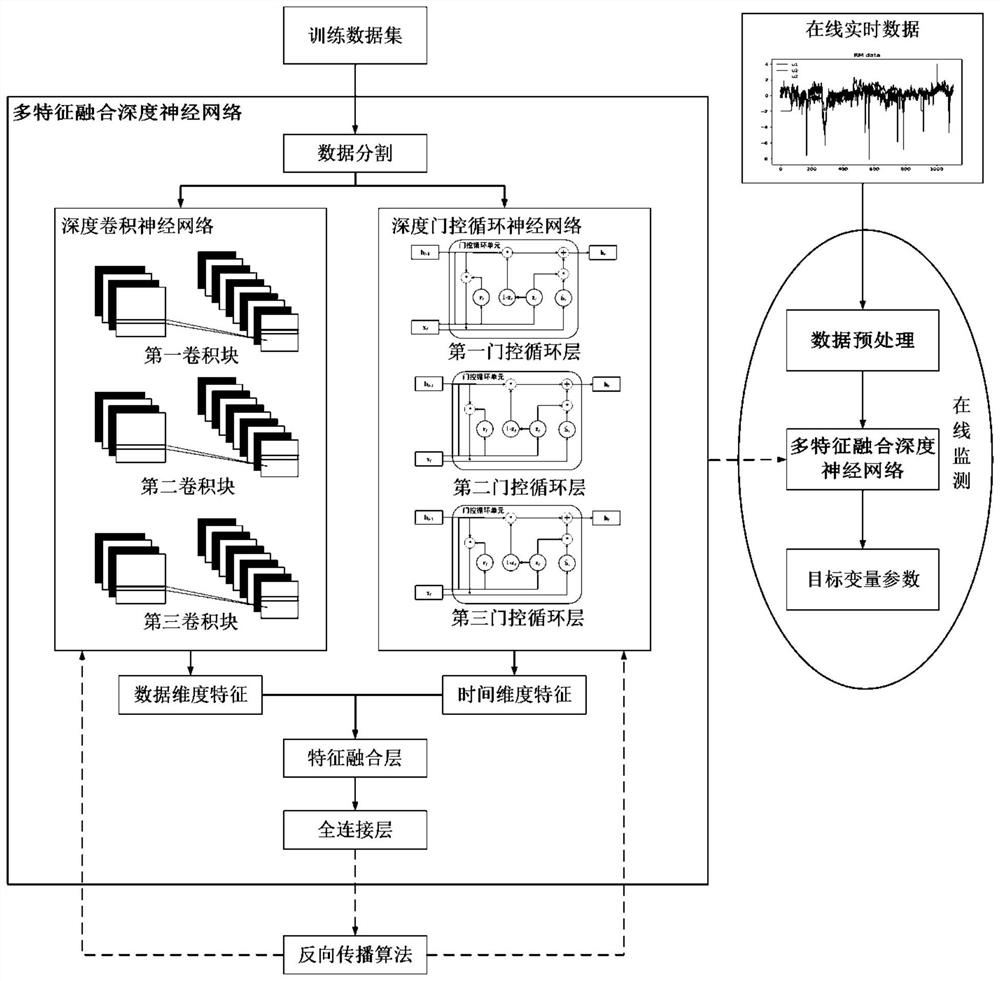

Industrial production process target data prediction method of multi-feature fusion deep neural network

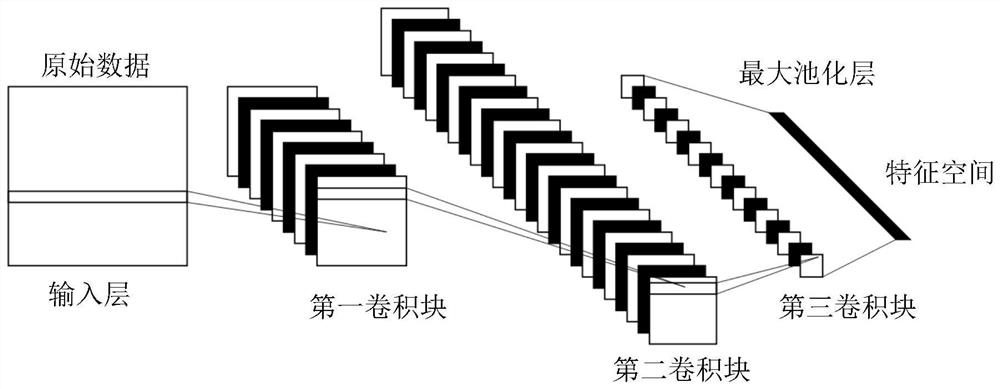

A deep neural network, multi-feature fusion technology, applied in the field of process industry production, can solve the problems of data dimension information being easily lost, gated recurrent neural network is not good at capturing data dimension, and the prediction effect is not ideal, etc., to achieve fast model update. , Improve the prediction accuracy and the effect of good accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with drawings and embodiments.

[0069] The embodiment implemented according to the complete method of the content of the present invention and its implementation process are as follows:

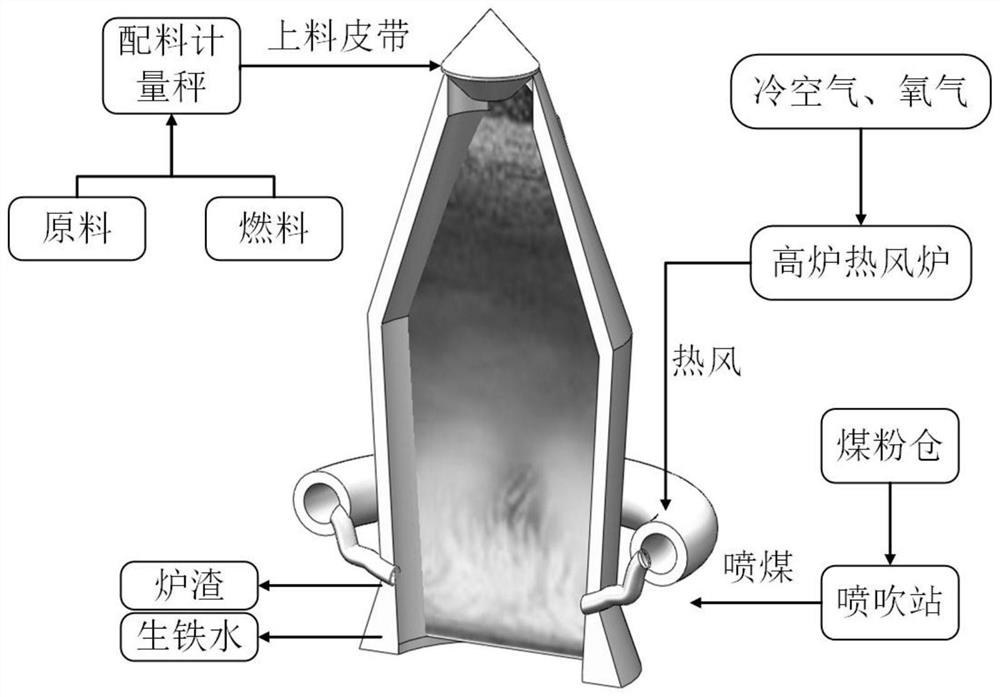

[0070] Specific Implementation The process industry data for the specific implementation of the present invention is the data measured by the blast furnace ironmaking process industrial production line of Baosteel Ironworks to implement the method of the present invention. Taking the process of predicting the silicon content of molten iron as an example, based on the specific processing process of the data, the key parameter prediction of the process industry is described in detail.

[0071] In specific implementation, the present invention regularly uses new fault-free data to update model parameters, so as to avoid failure of the model due to accumulated errors and decrease of prediction accuracy. Abnormal data ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com