Dynamic bearing intelligent sensing type pedestrian sole automatic cleaning device

A dynamic load-carrying, automatic cleaning technology, applied in household cleaning devices, cleaning equipment, cleaning of boots and shoes, etc., can solve the problems of large space occupation, troublesome installation, operation and maintenance, low intelligence, etc., and achieves safe, energy-saving and convenient use. Low purchase and maintenance costs, improved sanitation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

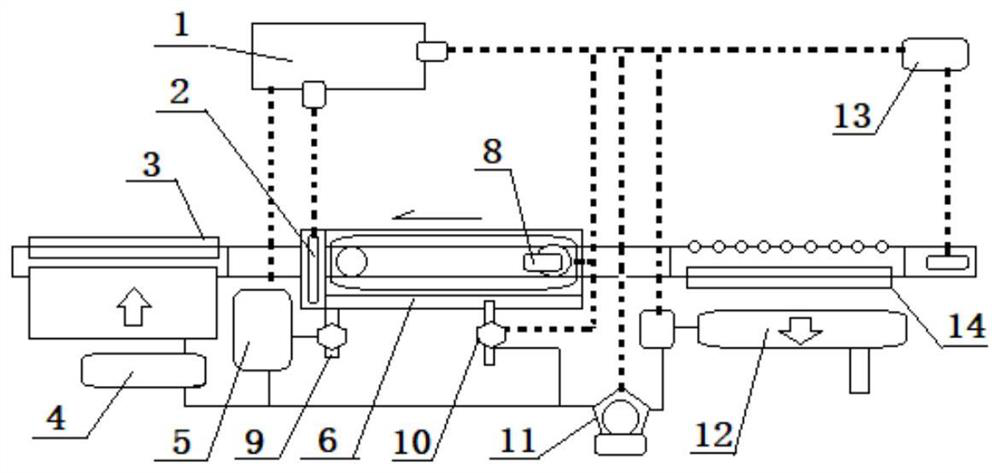

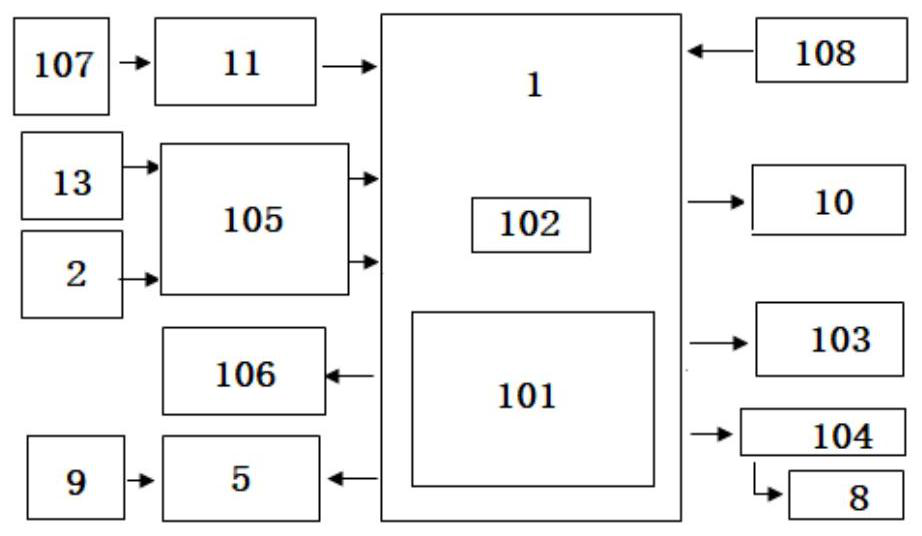

[0041] Embodiment 1: as attached figure 1 As shown, a single-chip microcomputer 1 and a power supply 11 are installed in the control equipment, and the cleaning equipment actuator includes a negative pressure dust collection box 14, an infiltration tank 6 and a dry air cushion 3 arranged in a linear order, wherein a radar sensor is installed on the negative pressure dust collection box 14 13. Install a water level sensor 2 and a cleaning motor 8 in the infiltration tank 6, and install a sewage discharge motor 5 on the sewage outlet at the bottom of the infiltration tank 6; as attached figure 2 As shown, a main controller 101 and a MOS tube 102 are installed in the single-chip microcomputer 1, and a button 108 connected to the single-chip microcomputer 1 is installed on the control device. The power supply 11, the radar sensor 13, and the water level sensor 2 are connected to the single-chip microcomputer 1. Water inlet solenoid valve 10, cleaning motor 8 and blowdown motor 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com