Preparation method and control method of micro-droplets

A technology of micro droplets and droplets, which is applied in the preparation of microspheres, microcapsule preparations, and the granulation of liquid into bead droplets, etc., can solve the problems of fragility of nozzles, high energy consumption, and high cost, and achieve controllable costs and simple and effective methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

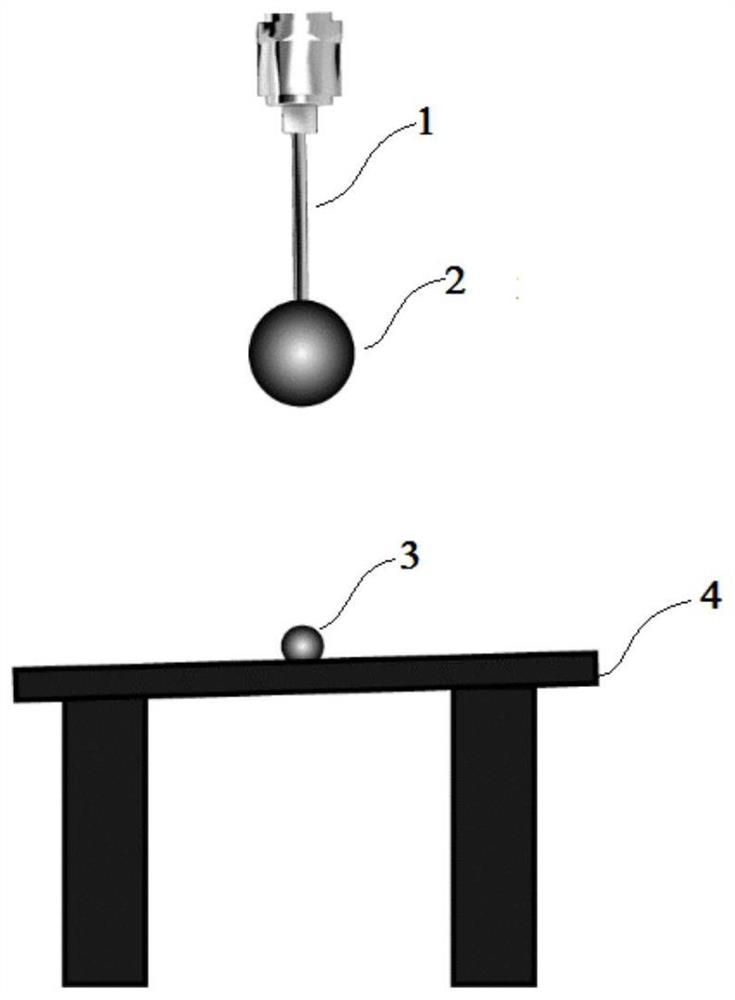

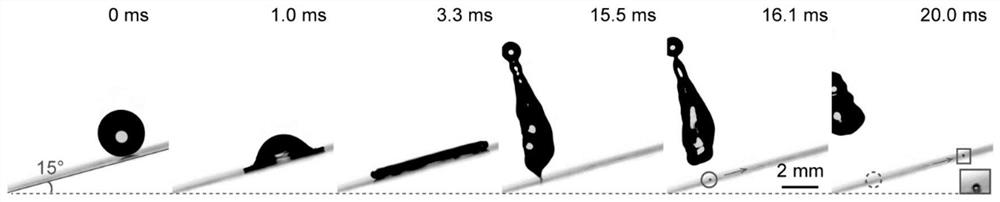

[0030] A controllable micro-droplet generation and manipulation method of the present invention, the schematic diagram of the micro-droplet generation device can be found in figure 2 shown. The device used in this method mainly includes a suspended platform for placing a superamphiphobic surface 4, a needle 1 for generating impacting droplets 2, and a high-speed photographic device for recording the process of producing microdroplets. Among them, the superamphiphobic surface to be impacted in this embodiment is a superamphiphobic surface of silica prepared with candle ash as a template, and thin glass with a thickness of 170 μm is selected as the preparation substrate. The preparation process steps are as follows:

[0031] Move the thin glass back and forth evenly over the burning candle flame to deposit a layer of candle ash, and then place it in a vacuum desiccator with 4ml tetraethyl silicate (TEOS) and 4ml ammonia water in the desiccator, respectively on both sides of th...

Embodiment 2

[0038] A controllable droplet generation and manipulation method of the present invention, embodiment 1 of a droplet generation device. The superamphiphobic surface to be impacted in this example is a silica superamphiphobic surface prepared with candle ash as a template, and thin glass with a thickness of 170 μm is used as the preparation substrate. The preparation process steps are as follows:

[0039] Move the thin glass back and forth evenly over the burning candle flame to deposit a layer of candle ash, and then place it in a vacuum desiccator with 4ml tetraethyl silicate (TEOS) and 4ml ammonia water in the desiccator, respectively on both sides of the sample. After the desiccator was sealed and evacuated, it was deposited by vapor phase deposition for 20 hours to obtain a composite surface filled with candle ash carbon particles and silicon dioxide particles. The sample was then placed in a muffle furnace for annealing at a high temperature of 540°C for 4 hours to remov...

Embodiment 3

[0046] A controllable droplet generation and manipulation method of the present invention, embodiment 1 of a droplet generation device. The superamphiphobic surface to be impacted in this example is a silica superamphiphobic surface prepared with candle ash as a template, and thin glass with a thickness of 170 μm is used as the preparation substrate. The preparation process steps are as follows:

[0047] Move the thin glass back and forth evenly over the burning candle flame to deposit a layer of candle ash, and then place it in a vacuum desiccator with 4ml tetraethyl silicate (TEOS) and 4ml ammonia water in the desiccator, respectively on both sides of the sample. After the desiccator was sealed and evacuated, it was deposited by vapor phase deposition for 20 hours to obtain a composite surface filled with candle ash carbon particles and silicon dioxide particles. The sample was then placed in a muffle furnace and annealed at a high temperature of 560°C for 2 hours to remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com