Preparation method of a two-dimensional nanosheet structure transition metal-n-c material and its application in lithium-sulfur batteries

A two-dimensional nano-transition metal technology, applied in the direction of lithium batteries, structural parts, battery electrodes, etc., to achieve the effects of enhanced conductivity, uniform nitrogen doping, and accelerated charge transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Weigh 3g of sodium chloride, 0.7g of glucosamine hydrochloride and 0.1g of ferric nitrate, dissolve them in 20mL of deionized water, stir and react for 40min, freeze at -12°C for 24h to form an ice crystal template, and freeze-dry for 12h to obtain carbonized Precursor.

[0018] In a tubular heating furnace, the carbonized precursor was heated to 800 °C for 3 h at a rate of 2 °C / min in an argon atmosphere, cooled to room temperature and then acid-washed with 1 mol / L HCl solution to wash away the salt template and load. The iron nanoparticles were freeze-dried to obtain a two-dimensional nanosheet structure Fe-N-C material. After the assembled battery test, the performance can reach 805mAh g under the test condition of 0.1C -1 .

Embodiment 2

[0020] Weigh 5g of sodium chloride, 1g of glucosamine hydrochloride and 0.3g of cobalt chloride, dissolve them in 30mL of deionized water, stir and react for 30min, freeze at -18°C for 12h, and freeze-dry for 12h to form an ice crystal template to obtain carbonized Precursor.

[0021] In a tubular heating furnace, the carbonized precursor was heated to 900 °C for 3 h at a rate of 2 °C / min in an argon atmosphere, and was cooled to room temperature and then acid-washed with 1 mol / L HCl solution to wash away the salt template and load. Cobalt nanoparticles were freeze-dried to obtain a two-dimensional nanosheet structure Co-N-C material. After the assembled battery test, the performance can reach 974mAh g under the test condition of 0.1C -1 .

Embodiment 3

[0023] Weigh 5g of sodium chloride, 0.5g of glucosamine hydrochloride and 0.1g of cobalt nitrate, dissolve in 25mL of deionized water, stir and react for 30min, freeze at -18°C for 12h, and freeze-dry for 12h to form an ice crystal template to obtain carbonized Precursor.

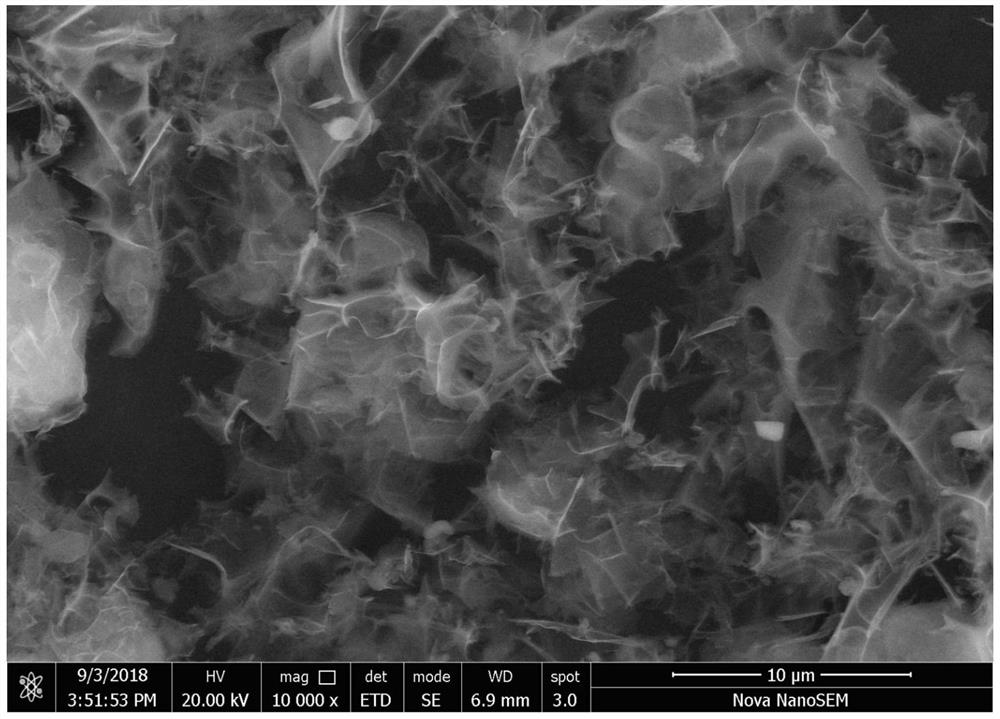

[0024] In a tubular heating furnace, the carbonized precursor was heated to 900 °C for 2 h at a rate of 2 °C / min in an argon atmosphere. After cooling to room temperature, it was acid-washed with 1 mol / L HCl solution to wash away the salt template and load. Cobalt nanoparticles, freeze-dried, and finally obtained a uniformly distributed ultrathin two-dimensional nanosheet structure Co-N-C material. After the assembled battery test, the performance can reach 1100mAh g under the test condition of 0.1C -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com